Explore all the information on

Feed pelletizing

Welcome to the page about Feed pelletizing of Engormix; a source of knowledge on Feed pelletizing.

Introduction Globally, feeding cost and the price of poultry product have recently increased due to increasing competition between human and animals for the same feed resources. Agriculture by-products are valuable feedstuffs that can be used in animal nutrition (Al-Harthi et al. 2018a, 2018b). In animal nutrition feed processing and feed additives as well have been used for improving the feeding values of feeds particularly of agricultural byproducts (Dozier et al. 2010;...

Comments : 0

Recommendations: 0

True that pellet should be hard enough to sustain handling process up to feeding. At the same time, too hard pellet may be not preferred by birds. Can anyone suggest the specification for good quality pellets for chicken? ...

Comments : 1

Recommendations: 0

FIGAP 2026: The Scientific And Technological Exhibition Of The Livestock Industry

Suggested link

1. Introduction The pelleting operation is one of the most expensive processes with regards to the fixed and variable costs. For this reason, efficient pellet production is aimed and pellet press should deliver a high yield of dust-free and resistant pellets to optimize the feed mill operations. Besides the types of ingredients,...

Comments : 0

Recommendations: 1

Integrators usually operate the mills at full capacity and outputs rather than trying to obtain the optimum pellet quality. The advantages of feeding a pelleted feed over mash have been documented in the industry for many years. The advantages include the following: Increased bulk density Less bridging/hang-up in bins Less dust Reduced ingredient segregation Less feed...

Comments : 13

Recommendations: 0

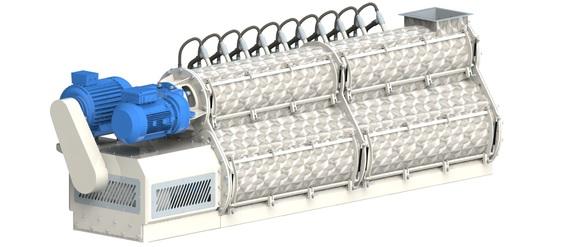

Pre- Pelleting Process in Aquafeed Production Josef Barbi (E.S.E. & Intec)

Suggested link

WILMINGTON, Del – DuPont Nutrition & Biosciences announced today the launch of the industry-leading novel phytase enzyme, Axtra® PHY GOLD. The enzyme offers superior performance compared to other phytases on the market, delivering greater feed cost savings to producers. Axtra® PHY GOLD will be available in the United States, Mexico and India and eventually worldwide, pending regulatory authorizations.

Recent scientific studies demonstrate that Axtra® PHY...

Comments : 0

Recommendations: 0

Introduction Pelleting is a feed processing method shown to improve handling and transportation characteristics of feeds, while reducing ingredient segregation during handling, decreasing dust levels, and improving feed utilization in swine. The use of flat die technology (cold pelleting) has received little attention at this point compared to thermal pelleting for commercial feed applications. Its unique advantage of layout (flat-bed compared to standard ring die) requires only...

Comments : 0

Recommendations: 1

Webinar: Accurate values drive better profit in poultry nutrition.

Suggested link

Dr. Kim Koch (North Dakota State University) talked about pellet mills and production, during the 22nd Annual Distillers Grains Symposium in Des Moines, Iowa....

Comments : 5

Recommendations: 3

One problem in fish-farming is the lack of knowledge on how to produce floating pellets for Tilapia feeds. I would like to hear different skills from others on what feed ingredients are good for floating pellet production. Thanks for your time ...

Comments : 0

Recommendations: 0

1. Introduction Pelleting is the most used thermal processing method in poultry industry. The aim of pelleting processing is to agglomerate ingredients particles by mechanical action, in combination with moisture, pressure and temperature. Broilers fed pelleted diets present greater feed intake, better feed conversion ratio and greater weight gain [1-3]. The positive effect of pelleting on broiler performance is partly due to improved nutrients digestibility [4], increased feed...

Comments : 5

Recommendations: 8

Phil Wellhausen is CPM's Applications Manager in Crawfordsville, Indiana. He presents the characteristics of the 9950 Pellet Mill, its advantages and how it operates. Productivity reaches over 100 tons per hour, operating 24/7. California Pellet Mill is headquartered in the U.S. and has over 80 years of tradition in engineering and applied pelleting knowledge. ...

Comments : 1

Recommendations: 5

FIGAP 2026: The Scientific And Technological Exhibition Of The Livestock Industry

Suggested link

I have been happier the few minutes spent here. We desire more discussion on the durability of pellet feeds in water. Durability of 2 hours still floating is much desired in the fish industry. Please, how achievable. Is it possible now?

I will like to get in this discussion. Extrusion Cooking Systems in feed production for fish, chicken and other animals. How finely pulverized should ingredients be before extrusion? ...

Comments : 7

Recommendations: 0

Fundamentals on feed mash conditioning and its impacts on component modification and bio-actives recovery The feed industry has the responsibility to develop and produce feeds for livestock and aquaculture sectors to meet the growing consumer demand for safe and sustainable...

Comments : 0

Recommendations: 2

Pre- Pelleting Process in Aquafeed Production Josef Barbi (E.S.E. & Intec)

Suggested link

Joe Moritz (West Virginia University) talked about pelleting, thermal processing and other relevant aspects of feed manufacturing, during the Multi-State Poultry Feeding and Nutrition Conference in Indianapolis, USA. ...

Comments : 2

Recommendations: 7

Today’s livestock are fed complete or complementary feed given mainly in the form of pellets. This form gives better animal performance (average daily gain and feed...

Comments : 0

Recommendations: 4

Webinar: Accurate values drive better profit in poultry nutrition.

Suggested link

1. Introduction Sorghum has been described as an enigmatic grain for chicken meat production because sorghum-based broiler diets have been associated with sub-optimal performance of chickens under Australian conditions (Selle et al., 2013). Six red 'tannin-free' grain sorghum varieties harvested on the Liverpool Plains of New South Wales in 2009 were extensively characterised and compared in broilers offered sorghum-casein diets (Khoddami et al., submitted for publication). On...

Comments : 0

Recommendations: 0

Because of its high density, large capacity and good palatability, the feed pellet machine is very popular among farmers and feed processing manufacturers. The production volume and mechanical performance of the pellet machine are closely related to the production efficiency. In actual operation, many farmers use pellets because of low production, high wear and tear, and frequent replacement of parts. In terms of factors that restrict the yield of pellets, please explain: 1. If the machine...

Comments : 0

Recommendations: 0

Introduction The efficient use of feed is extremely important in broiler production. Investigations have to be continued to decrease cost of broiler production and improve broiler performance. Pellet feed has been shown to have the greatest potential to improve feed conversion ratio (FCR) and reduce cost compared to mash feed (Maiorka et al. 2005, Salari et al. 2006, Amerah et al. 2008). These improvements have been associated with changes in nutrients, digestibility and less...

Comments : 1

Recommendations: 1

Dear all, In the aim to create a full ration mix that includes ( pellets + flakes + forage ) What is the best type of mixer to use in order to avoid flake and pellet from breaking. Regards ...

Comments : 0

Recommendations: 0

FIGAP 2026: The Scientific And Technological Exhibition Of The Livestock Industry

Suggested link

Conditioning is a process of hydrothermal treatment of powdery materials before pelleting of pellet feed. Domestic and foreign studies show that conditioning is one of the important factors affecting the quality of pellet feed, and it accounts for about 20% in the overall quality of pellet feed.

Learn more about #the role of conditioner in pellet feed processing# at: http://www.zhengchang.com/eng/index.aspx?cat_code=Zhengchang%20News...

Comments : 3

Recommendations: 0

Dear sir In my plant, Andritz pellet mill 60 tph , the die was not freely rotate by hand when the machine was stopped,(The main bearing changed 3 months back, main motor amps normal, out put also good) Kindly gives your advice Arul Anand M ...

Comments : 1

Recommendations: 0

.jpg&w=3840&q=75)