Fuel Ethanol Coproducts for Livestock Diets

Published: December 2, 2014

By: Kurt A. Rosentrater (Distillers Grains Technology Council, and Department of Agricultural and Biosystems Engineering, Iowa State University), Kenneth Kalscheur (USDA, Agriculture Research Service), Alvaro Garcia (Dairy Science Department, South Dakota State University), Cody Wright (Department of Animal and Range Science, South Dakota State University)

Introduction

The objective of this article is to briefly describe the most common ethanol coproducts, how they are produced, and typical nutrient compositions. Rapid growth of the ethanol industry in the United States over the last decade has generated large quantities of ethanol coproducts, which are now commonly available as feedstuffs for livestock. These coproducts are often added to livestock diets as a source of protein and energy. The protein supplied can be degraded in the rumen to a variable extent, depending on the coproduct, while energy is provided by fat and highly fermentable fiber. Mineral concentrations in the coproducts can sometimes be variable, which must be considered when formulating diets for livestock to prevent excessive dietary mineral concentrations. As the ethanol industry continues to evolve, new or altered coproducts are beginning to appear in the marketplace. There is a need to nutritionally define these products and to determine their best use in livestock diets.

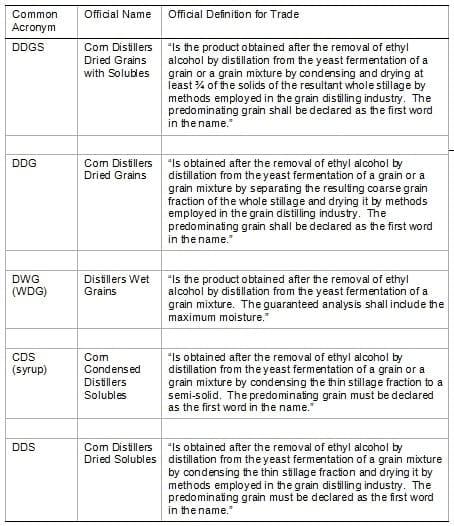

Ethanol production (wet milling and dry grind)

Two main techniques are used to produce ethanol from cereals, especially maize (corn): wet milling and dry grind processing. The corn wet milling process has been thoroughly reviewed by Johnson and May (2003). This process (Figure 1) consists of steeping the raw corn to moisten and soften the kernels, milling, and then separation of the kernel components through various processes including washing, screening, filtering, and centrifuging. Historically, the primary end products obtained from corn wet milling are industrial corn starch which is utilized for sweeteners, corn oil, and ethanol (Johnson and May, 2003). Additional end-products from the wet milling process include several feed coproducts, including corn gluten feed (CGF), corn gluten meal (CGM), corn germ meal (CGM), and condensed fermented corn extractives (CFCE) (Loy and Wright, 2003). The coproduct streams from corn wet milling account for approximately 30% of the raw corn input (typically 24% is converted into CGF while about 6% ends up asCGM); nearly 66% of the corn kernel is actually converted into starch, and 4% ends up as corn oil (Johnson and May, 2003). These coproducts, however, are distinct entities compared to distillers grains, which are coproducts from dry grind processing.

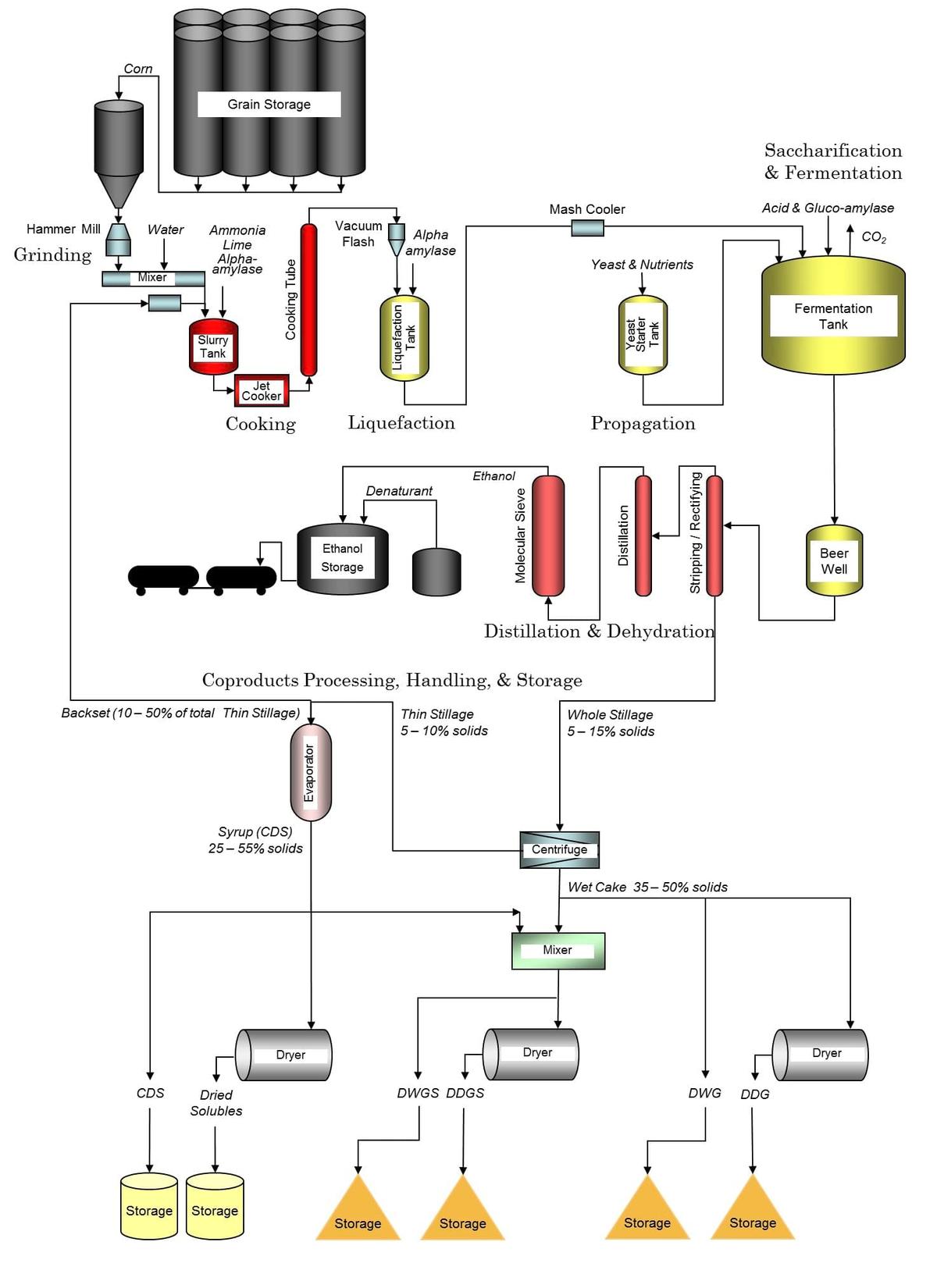

Because of its lower investment and operational requirements, and advances in fermentation technology, dry grind processing (Figure 2 and Figure 3) has become the primary method for ethanol production in the U.S. In this approach, the entire corn kernel is used during the fermentation process (Bothast and Schlicher, 2005). Corn is screened and then hammer-milled to a medium/coarse to fine grind meal. The resulting flour is combined with water to form a slurry, and enzymes are added to begin to break the starch down into glucose molecules. The resulting mash is then cooked and sterilized to kill non-desirable bacteria and to gelatinize the starch. Once cooled, enzymes continue to break down the starch, yeast (Saccharomyces cerevisiae) is added to the mash, and the glucose is then converted to ethanol and carbon dioxide during yeast metabolism (i.e., fermentation). After fermentation, ethanol is extracted in the distillation process, and the remaining water and solids are collected and referred to as whole stillage (Figure 3). Whole stillage can be pressed, but it is more commonly centrifuged to separate the coarse solids from the liquid. The liquid is referred to as distillers solubles or thin stillage. Thin stillage is frequently concentrated in evaporators to become condensed distillers solubles (CDS), also referred to as syrup. The wet coarse solids, or wet cake, collected from the centrifuge are known as distillers wet grains (DWG). Distillers wet grains and CDS can be combined to form distillers wet grains with solubles (DWGS), which can then be dried to produce DDGS.

As a rule of thumb, each 1.0 bushel of corn (56 lb;25.4 kg) will be converted into approximately2.8 gal(10.6 L) of ethanol,18 lb(8.2 kg) of carbon dioxide, and18 lb(8.2 kg) of nonfermentable solids (which are then sold as feed coproducts). Or, put another way, each kernel of corn will result in about 1/3, 1/3, and 1/3 of the resulting products, respectively. Numerous companies are developing modifications to this dry grind process that may result in the development of new coproducts that can be used in livestock diets.

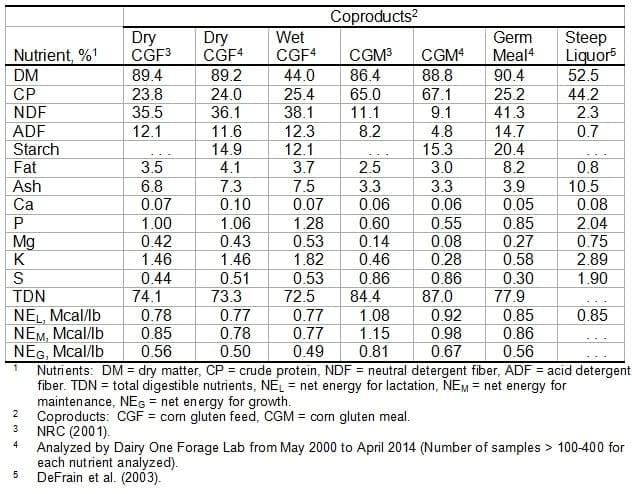

Wet milling coproducts

Processes in wet milling plants are considerably different than those in dry grind ethanol plants. This results in coproducts with differing nutrient profiles. The primary coproducts that from wet milling include corn gluten feed (CGF), corn gluten meal (CGM), corn germ meal (CGM), and condensed fermented corn extractives (CFCE; also referred to as corn steep liquor) (Loy and Wright, 2003). Typical nutrient compositions of wet milling coproducts are presented in Table 1.

Corn gluten feed

Corn gluten feed (CGF; Figure 4) is comprised primarily of the portion of the kernel that remains after the starch, gluten, and germ have been removed. It is produced by combining the remaining corn bran with steep liquor, and is commonly available as either dry or wet CGF. Nutrient composition can vary among different plants, depending on the amount and type of steep liquor added to the bran (Wickersham et al., 2004). For example, CGF is commonly reported as having approximately 24% crude protein (CP) (NRC, 2001), although others have reported 16.5% CP (Wickersham et al., 2004). The protein in CGF is predominantly rumen-degradable protein (RDP), and is thought to contain a similar percentage of crude protein (as RDP) as does soybean meal. Corn gluten feed has long been recognized as a source of digestible fiber, making it a common ingredient in ruminant diets. The digestible neutral detergent fiber (NDF) is often used as a replacement for corn. One concern regarding the use of CGF in ruminant diets is the high concentration of phosphorus (often greater than 1%). Excretion of phosphorus can be increased if diets are formulated in excess of the animal’s phosphorus requirement.

Corn gluten meal

Corn gluten meal (CGM; Figure 5) is comprised primarily of the gluten protein stream which is separated from the starch after the removal of the germ and fiber. It is high in CP and low in fiber (Table 1), making it a common ingredient in non-ruminant livestock diets. If fed to ruminants, it is important to note that its CP is highly undegradable in the rumen. Mineral concentrations can be high inCGM, especially sulfur.

Corn germ meal

Corn germ meal results from the solvent extraction of the oil from whole corn germ. It is often high in fiber with moderate levels of CP, fat, and starch (Table 1). Corn germ meal is highly digestible and is a common ingredient in non-ruminant diets. Of the minerals, phosphorus can be particularly high in corn germ meal because the phosphorus in corn is concentrated in the germ. It should be noted that new fractionation processes in dry grind ethanol plants are also producing a corn germ product. Nutrient composition of corn germ meal from wet milling and corn germ from dry grind processing can be considerably different; therefore it is important to obtain a nutrient analysis of the feedstuff prior to its use.

Corn steep liquor

Corn steep liquor (also known as condensed fermented corn extractives, or CFCE) is the liquid fraction obtained from the corn steeping process. Corn steep liquor is a mixture of soluble protein, carbohydrates, vitamins, and minerals (Table 1). The nitrogen fraction is generally high in free amino acids and small peptides. Of the minerals, steep liquor is often high in phosphorus, potassium, and sulfur.

Dry grind coproducts

Distillers grains are coproducts from dry grind ethanol plants, and can be produced as distillers dried grains (DDG or DDGS; Figure 3 and 6) or distillers wet grains (DWG or DWGS), with or without solubles (Figure 3 and 7). It should be noted that the official AAFCO (2014) definitions (Table 5; which are required for trade) for ethanol coproducts places the form (wet or dried) after the word “distillers” and before the word “grains”. Even so, DWGS and WDGS are often used interchangeably in the feed industry. Many cereal grains, such as sorghum, wheat, or barley can be used to produce ethanol, although corn is the predominant grain used in theUnited States. In the AAFCO definitions of various types of distillers grains, the predominating grain must be the first word in the name.

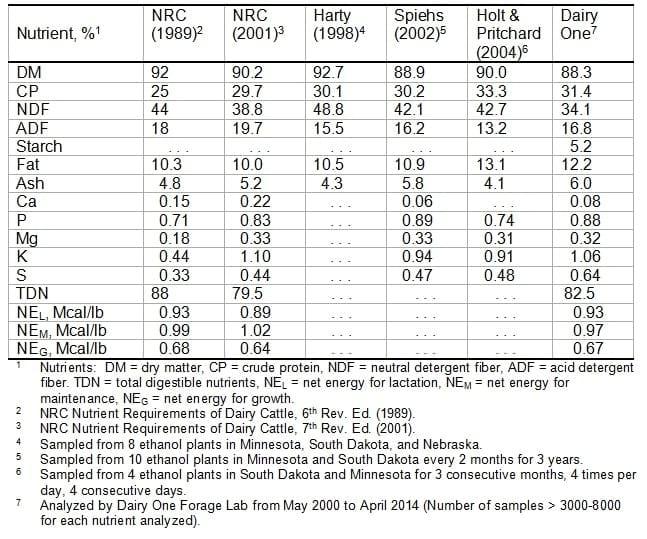

Knowing accurate nutrient composition of ethanol coproducts is critical when formulating diets for livestock. Conducting nutrient analyses of purchased ethanol coproducts is highly recommended, although it is not always practical for every shipment or delivery. Nutrient information should be provided by the ethanol plant in the form of a “feed tag”. Tables 2, 3, and 4 provide typical nutrient compositions of ethanol coproducts from various ethanol plants located mostly in the upper MidwestU.S. The NRC values are book values published in the Nutrient Requirements of Dairy Cattle (1989, 2001). In addition, many researchers at various universities, such as Iowa State University, South Dakota State University (Holt and Pritchard, 2004), University of Minnesota (Harty et al., 1998; Spiehs et al., 2002), and University of Wisconsin (Kaiser, 2005) have analyzed distillers grains samples from numerous ethanol plants in Minnesota, Nebraska, South Dakota, and Wisconsin. Nutrient composition of ethanol coproducts is influenced by factors such as the type and quality of the grain, milling and fermentation processes, drying temperatures, the amount of solubles added back to the wet coproducts before drying, and the amount of distillers oil removed from the stillage streams.

Distillers dried grains with solubles

Distillers dried grains with solubles (DDGS) is produced by mixing DWG with CDS and then drying the mixture. Ethanol coproducts have changed significantly since the 1990’s, when they were primarily derived primarily from the alcoholic beverage (i.e., whiskey) industry. Since the mid-1990’s, there has been tremendous growth in the fuel ethanol industry. The DDGS produced from these plants is sometimes referred to as “new generation” DDGS. Nutrient composition of these new DDGS materials has improved over the last 10 years. For example, DDGS produced from modern dry grind ethanol plants typically contains more protein and energy than previous reference values (NRC, 1989). The newest dairy NRC (2001), for example, lists DDGS crude protein (CP) at 29.7%, which is quite close to current values seen in industry (Table 2). Average CP for DDGS is around 30%, but these studies illustrate that CP values ranging from 27 to 34% are not unusual. DDGS is also a good source of rumen-undegraded protein (RUP). Most reported values range from 47% to 57% RUP; although research in recent years suggests that RUP may actually be higher than that. For example, some studies have determined the RUP of multiple sources of DDGS, which ranged from 59.1 to 71.7% (Kleinschmit et al., 2007).

The fatty acid composition in distillers grains (wet or dry) reflects the composition of corn oil, and typically have a high level of unsaturation, predominantly linoleic acid (C18:2). Additionally, distillers grains provide substantial concentrations of minerals, which can pose challenges to nutrient management plans when fed above animal requirements. Most traditional distillers grains contain between 0.6% and 0.9% (dry matter basis) phosphorus, and animal requirements for this mineral are easily attained when distillers grains are included in the diet. The other mineral that can be highly variable is sulfur. High sulfur concentrations in feed and water can result in central nervous system disorders (known as polioencephalomalacia) in cattle, which can lead to poor performance or even death. Therefore sulfur levels need to be monitored for total dietary intake.

Distillers wet grains (with or without solubles)

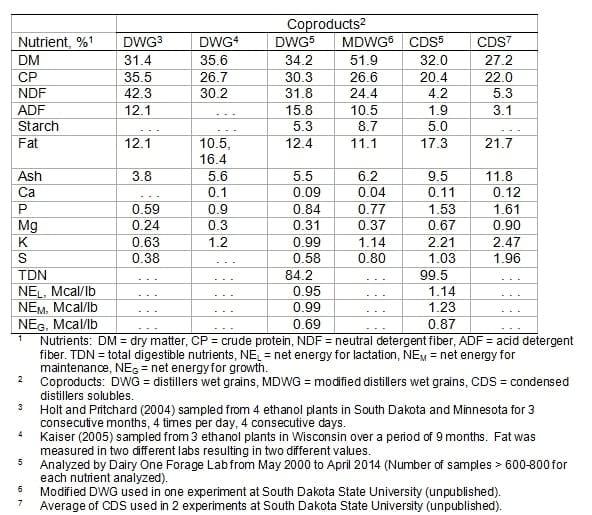

Distillers wet grains, with or without solubles (DWG or DWGS), is sold prior to drying. Traditional distillers wet grains contains 30 to 35% DM (dry matter) (Table 3) and, on a dry basis, is similar in nutrient composition to DDG or DDGS. As shown in Table 3, the nutrient composition of DWGS can vary considerably, as reported by various studies (Holt and Pritchard, 2004; Kaiser, 2005). These wet coproducts are often considerably lower in price, on a dry matter basis, compared to DDGS, but the livestock producer must determine if they can be successfully used in his/her operation. There are benefits to using wet coproducts in cattle diets, particularly because of high palatability, and the fact that they can condition diets that are particularly dry. Total mixed rations that contain 10-20% DWG or DWGS on a DM basis can maintain greater homogeneity as dry particles are distributed in the mix. From a practical standpoint, this will result in less particle separation and less sorting by livestock. Methods to preserve, equipment to handle, and facilities to store wet coproducts on the farm are among the challenges that producers must determine if they can manage.

Modified distillers wet grains with solubles

Modified distillers wet grains with solubles (MDWG) are distillers grains that have either undergone partial drying or been completely dried to DDGS and then had CDS added back to achieve a higher moisture coproduct. Dry matter of MDWG is typically between 45 and 55%. Nutrient composition is typically similar to values reported for DWGS and DDGS (Table 3), but again, can vary depending on processing conditions, especially the amount of CDS added back to make the final product. Nutrient composition of MDWG can vary from plant to plant; therefore, nutrient analysis is recommended prior to use in specific diets.

Condensed distillers solubles

Condensed distillers solubles (CDS) is also commonly referred to as “syrup” or “solubles”. It contains similar DM% to that of DWG (27 to 35%). But compared to other types of coproducts, CDS is higher in fat (and consequently energy), lower in fermentable carbohydrates (such as fiber), but much higher in minerals (Table 3). Minerals such as phosphorus, potassium, and sulfur are proportionally greater in CDS compared to the solids portion of the grains. Thus, as more CDS is added back to the grains, fat and minerals increase, but CP decreases in the final coproduct. Syrup can be sold separately as-is, but often most ethanol plants just add it back in during DWG and/or DDGS processing. Condensed distillers solubles can also be dried to create dried distillers solubles, but this practice is not so common any more.

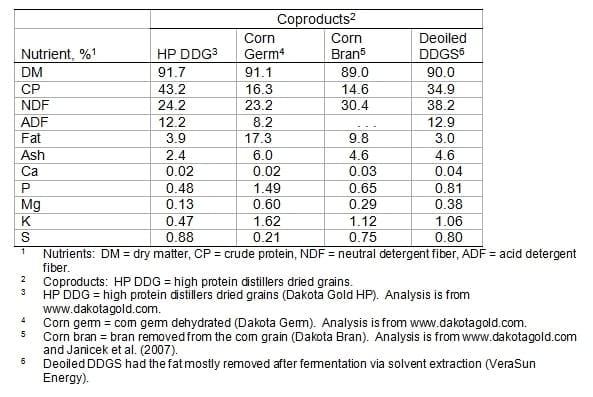

Evolving ethanol coproducts

Until recently, most coproducts resulted from either traditional corn dry grind ethanol plants or from corn wet milling plants. As new processes have been employed, however, new coproducts from the ethanol industry have emerged. Fractionation is key to the evolution of coproducts. In one approach, corn is milled into several fractions prior to fermentation so that the resulting products can be directed into different processing streams (Gibson and Karges, 2006). This pre-fermentation fractionation results in new coproducts, such as high protein DDG (HP DDG), corn germ dehydrated, and corn bran. Furthermore, syrup can also be added to the bran, resulting in a product being marketed as bran cake (Gibson and Karges, 2006). Examples of these feeds are shown in Table 4. These products are proprietary and therefore are specific to individual companies. As a result, the nutrient compositions of these streams may vary significantly, depending on the company of origin.

In pre-fermentation fractionation, each fraction contains nutrients specific to the kernel component from which they originate. The bran is the seed coat of the corn kernel; therefore it will contain more fiber, but less protein. The germ has low starch concentration, but is rich in fats and phosphorus. However, because the germ does not go through the fermentation process and is not combined with CDS, it contains substantially less sulfur than other coproducts. The HP DDG results from fermenting the separated endosperm, where most of the starch is located. In this particular product, the CDS is not added back, making it a true DDG (with no solubles) (Gibson and Karges, 2006).

Another new coproduct on the horizon is low-fat, or deoiled DDGS (Table 4), where the oil is mostly removed from the DDGS post-fermentation using solvent extraction. Oil removed from the DDGS can be sold for use in animal feed or for biodiesel production. Deoiled DDGS is low in fat (it contains 2.5 to 3%) and is proportionally higher in protein, fiber, and minerals than traditional DDGS due to the removal of the oil. Deoiled DDGS is not yet commercially available, but may be in the near future.

Because of the growing demand for oil by the animal feed and biodiesel industries in recent years, many ethanol plants (>85% by now) have installed equipment (such as heating tanks and disk stack centrifuges) to remove oil (Figure 8) after fermentation from either the whole stillage or the CDS streams. Only some of the oil is removed, though, so the resulting coproducts will have fat contents higher than deoiled DDGS, but lower than traditionally-produced coproducts (Tables 2 and 3).

Summary

Fuel ethanol coproducts have been shown to be economical ingredients for a variety of livestock diets. However, because their nutrient composition can vary somewhat amongst the plants, it is important to obtain guaranteed analyses of these coproducts when formulating them into livestock diets. In the next few years, it is expected that ethanol coproducts will continue to evolve as new ethanol production processes are developed. Thus the nutrient compositions of ethanol coproducts will likely shift compared to today’s profiles, which will make it even more important that end users understand the nutrient compositions of the materials they are using in order to determine how best they will fit into their livestock diets.

References

AAFCO. 2014. Official Publication. Association of American Feed Control Officials, Inc.,Oxford,IN.

Bothast, R. J. and M. A. Schlicher. 2005. Biotechnological processes for conversion of corn into ethanol. Appl. Microbiol. Biotechnol. 67: 19-25.

Dairy One Forage Lab. 2014. Interactive feed composition libraries. Available online: http://dairyone.com/analytical-services/feed-and-forage/feed-composition-library/interactive-feed-composition-library/. Accessed December 2014.

DeFrain, J. M., J. E. Shirley, K. C. Behnke, E. C. Titgemeyer, and R. T. Ethington. 2003. Development and evaluation of a pelleted feedstuff containing condensed corn steep liquor and raw soybean hulls for dairy cattle diets. Anim. Feed Sci. Technol. 107: 75-86.

Gibson, M. L. and K. Karges. 2006. By-products from non-food agriculture: Technicalities of nutrition and quality. Recent Advances in Animal Nutrition, pp. 209-227. Nottingham University Press, Nottingham, UK.

Harty, S. R., J-M. Akayezu, J. G. Linn, and J. M. Cassady. 1998. Nutrient composition of distillers grains with added solubles. J. Dairy Sci. 81: 1201 (Abstr).

Holt, S. M. and R. H. Pritchard. 2004. Composition and nutritive value of corn co-products from dry milling ethanol plants. South DakotaBeef Report, BEEF 2004-01, pp. 1-7. Available online: http://www.sdstate.edu/ars/species/beef/beef-reports/upload/BEEF_2004-01_Pritchard.pdf. Accessed December 2014.

Janicek, B. N., P. J. Kononoff, A. M. Gehman, K. Karges, and M. L. Gibson. 2007. Short Communication: Effect of increasing levels of corn bran on milk yield and composition. J. Dairy Sci. 90: 4313-4316.

Johnson, L. A. and J. B. May. 2003. Wet milling: the basis for corn biorefineries. Corn Chemistry and Technology, P. J. White and L. A. Johnson (eds), pp. 449-494. American Association of Cereal Chemists, Inc.,St. Paul,MN.

Kaiser, R. M. 2005. Variation in composition of distillers wet grains with solubles. Proceedings of the 4-State Dairy Nutrition & Management Conference, pp. 191-197. Dubuque,IA.

Kleinschmit, D. H., J. L. Anderson, D. J. Schingoethe, K. F. Kalscheur, and A. R. Hippen. 2007. Ruminal and intestinal degradability of distillers grains plus solubles varies by source. J. Dairy Sci. 90: 2909–2918.

Liu, K. and K. A. Rosentrater. 2011. Distillers Grains: Production, Properties, and Utilization. CRC Press,Boca Raton,FL.

Loy, D.D.and K. N. Wright. 2003. Nutritional properties and feeding value of corn and its by-products. Corn Chemistry and Technology, P. J. White and L. A. Johnson (eds), pp. 571-603. American Association of Cereal Chemists, Inc., St. Paul, MN.

National Research Council (NRC). 1989. Nutrient Requirements of Dairy Cattle, 6th rev. ed. National Academies Press,Washington,DC.

National Research Council (NRC). 2001. Nutrient Requirements of Dairy Cattle, 7th rev. ed. National Academies Press,Washington,DC.

Spiehs, M. J., M. H. Whitney, and G. C. Shurson. 2002. Nutrient database for distillers dried grains with solubles produced from new ethanol plants inMinnesotaandSouth Dakota. J. Anim. Sci. 10: 2639-2645.

Wickersham, E. E., J. E. Shirley, E. C. Titgemeyer, M. J. Brouk, J. M. DeFrain, A. F. Park, D. E. Johnson, and R. T. Ethington. 2004. Response of lactating dairy cows to diets containing wet corn gluten feed or a raw soybean hull-corn steep liquor pellet. J. Dairy Sci. 87: 3899-3911.

Table 1. Nutrient composition (dry matter basis) of corn coproducts from the wet milling industry.

Table 2. Nutrient composition (dry matter basis) of distillers dried grains with solubles (DDGS) from various published references.

Table 3. Nutrient composition (dry matter basis) of distillers wet grains with solubles (DWGS), modified distillers wet grains with solubles (MDWG), and condensed distillers solubles (CDS) from various published references.

Table 4. Nutrient composition (dry matter basis) of recently-developed corn coproducts from the ethanol industry.

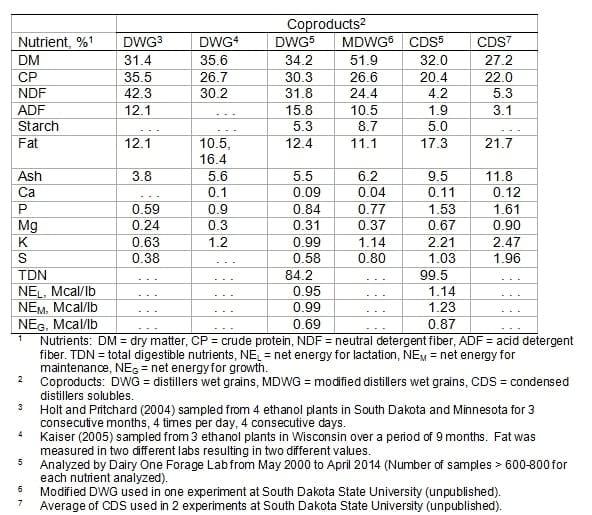

Table 5. Common and official coproduct names and definitions (as delineated by AAFCO, 2014).

Figure 1. Flow chart for processing corn by wet milling into fuel ethanol and other products (based, in part, on Loy and Wright, 2003).

Figure 2. Large-scale corn-based fuel ethanol plant (photo courtesy of K. A. Rosentrater)

Figure 3. Flow chart for processing corn by dry-grinding into fuel ethanol and coproducts (based on Liu and Rosentrater, 2011).

Figure 4. Corn gluten feed (photo courtesy of K. A. Rosentrater

Figure 5. Corn gluten meal (photo courtesy of K. A. Rosentrater).

Figure 6. Distillers dried grains with solubles (DDGS) (photos courtesy of USDA, ARS and K. A. Rosentrater).

Figure 7. Distillers wet grains (DWG) (photo courtesy of K. A. Rosentrater)

Figure 8. Distillers Oil, Feed Grade, is being extracted from nearly 85% of allU.S.ethanol plants in 2014 (photo courtesy of K. A. Rosentrater)

Related topics:

Authors:

Iowa State University

South Dakota State University

South Dakota State University

South Dakota State University

Show more

Recommend

Comment

Share

Recommend

Reply

5 de diciembre de 2014

My question is to you, dear prof.

How far will continue the racing of working on each of industrial by- products and co-products hoping to be as foodstuffs and eaten by livestock instead of feeding them as natural.

Recommend

Reply

Would you like to discuss another topic? Create a new post to engage with experts in the community.

.jpg&w=3840&q=75)