Egg Quality and Food Safety of Table Eggs

Published: July 26, 2013

By: J.R. Roberts (University of New England) and K.K. Chousalkar (University of Adelaide,)

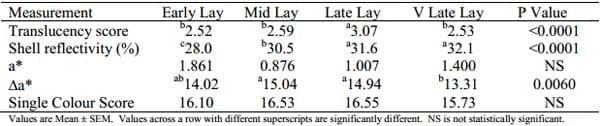

This study is an update of data presented previously (Roberts & Chousalkar, 2012) from a study which investigated egg quality at different stages of lay. Although eggs produced in Australia are considered medium to low risk for food borne illness, the egg industry in Australia is periodically implicated in cases of food poisoning. Egg shell defects may potentiate the movement of bacteria into the egg. Two egg shell characteristics were targeted: the extent of cuticle cover and the incidence of translucency. Eggs were collected from commercial caged layer flocks at different stages of lay: early (<25-40 wks), mid (40-55 wks), late (55-65 wks) and very late (>65 wks). Eggs were candled and scored for translucency. Cuticle cover was estimated using MST cuticle stain and a Konica Minolta hand-held spectrophotometer (L*a*b* colour scale). Traditional measures of egg quality were determined using specialised equipment (TSS, U.K.) Shell ultrastructural features were scored following plasma ashing of shell samples and viewing under a benchtop scanning electron microscope. Translucency score increased in late lay and then decreased in the very late flocks, which had been moulted (Table 1). As flock age increased, egg shell quality and egg internal quality decreased although quality was improved to some extent in late lay flocks following an induced moult. Cuticle cover, as measured by a* or the single score (Leleu et al., 2011) was not significantly affected by flock age although the difference between before and after staining, ?a*, was highest for the mid and late lay flocksindicating a trend to better cuticle cover at these ages. The incidence of unfavourable shell ultrastructural features was higher for older flocks and the incidence of favourable ultrastructural features was lower. The differences in mammillary layer characteristics among flock ages is consistent with the findings of previous researchers (Brackpool, 1995; Solomon, 1991) and with the traditional measures of shell quality. The limited number of correlations between egg shell translucency scores and the scores obtained from examination of the mammillary layer of the egg shells suggest that the ultrastructure scoring system only partly accounts for the phenomenon of shell translucency. Cuticle blue dye was a reliable indicator of the presence of cuticle.

Table 1 - Egg Quality Measurements

ACKNOWLEDGEMENT: This research was conducted within the Poultry CRC, established and supported under the Australian Government's Cooperative Research Centres Program. The participation of Rowly Horn and egg industry producers is very much appreciated.

Leleu S, Messens W, De Reu K, De Preter S, Herman S, Heyndrickx M, DE Baerdemaeker J, Michiels CW, Bain M (2011) J. Food Prot. 74(10), 1649–1654.

Roberts JR, Chousalkar KK (2012) Proc. Aust. Poult. Sci. Symp. 23, 241-244.

Content from the event:

Related topics:

Authors:

University of New England

Recommend

Comment

Share

26 de septiembre de 2013

dear author, I am happy to see your article and target is if shell quality of eggs are not taken care there may be invasion of bacterial population which are not safe for human consumption.

-egg shell quality has good genetic support for finding out shell thickness and selections are made accordingly for improvement or retaining the good status.

-Nutritional impact and seasonal impact are always play a role to show the shell status .

-it has been also thought to market the liquid egg and frozen egg instate of whole eggs which attract losses due to shell quality.

-in cage layer the changes of bacterial invasion in to egg due to poor cuticle would be less than the deep litter system.

-But shell thickness of egg remain the vital point always.the farmer has to review every week to manage the nutrition to over come such situation.

-May i know how you suggest to over come for high yielding layers who lay around 330eggs per 72wk of age. I feel it is the farmer who need to update his feed and feed quality for best caco3 assimilation over the egg shell structure to maintain the status which will increase the keeping quality in cage layer system.

-if you say no cage then there is less keeping quality for some period and may lead to bacterial fermentation of the albumin and yolk.

-Let us concentrate with liquid egg marketing which will solve more such points-situations.thank you sir.dr m rath

Recommend

Reply

Would you like to discuss another topic? Create a new post to engage with experts in the community.

.jpg&w=3840&q=75)