The effect of supplementing xylanase (Xylamax) on performance of commercial broilers fed decreasing levels of metabolizable energy

Published: April 26, 2021

By: S. V. Rama Rao¹, G. Shah¹, JJ Wang², ¹Directorate of Poultry Research, Hyderabad, India, ²BioResource International, Inc., Durham, NC, USA

Introductions:

Non-starch polysaccharides (NSPs) encapsulated in feed grains' cell walls contain valuable nutrients that may be wasted since some animals' endogenous enzymes cannot digest them. Xylanase feed additives degrade grain cell walls, releasing entrapped nutrients to the animal.

The soluble portion of NSPs increase digesta viscosity, slowing the passage of feed through the digestive system and preventing an animal's natural enzymes from acting upon nutrients in the diet. Certain xylanase feed additives may act to reduce digesta viscosity, improving overall digestion and gut health.

The purpose of this experiment was to evaluate the effect of supplementing Xylamax (1,4-beta-xylanase) on performance of commercial broilers fed decreasing levels of metabolizable energy, under Indian conditions, when broilers were fed corn-soybean meal based diets from 0 to 42 days of age.

Materials and Methods:

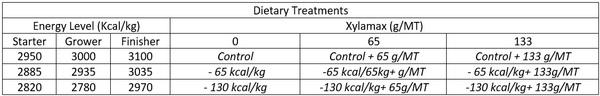

2700 Cobb 400 broiler chickens were randomly assigned to 1 of 9 dietary treatments, with 12 replicate pens of 25 birds each. The nine dietary treatments were arranged in a 3 x 3 factorial of metabolizable energy (ME) and Enerxyme inclusion. Birds were reared for 42 days and fed corn-SBM mash diets ad libitum. Feed energy content was adjusted using vegetable oil. ME values of the control treatments were 2,950, 3,000 and 3,100 kcal/kg in the pre-starter (0-14 days), starter (15-28 days) and finisher (29-42 days), respectively. While two other ME levels were 65 kcal/kg and 130 kcal/kg less than the control.

Key Parameters evaluated:

- Body weight gain (BWG)

- Feed Intake (FI)

- Feed conversion ratio (FCR)

Results and Discussion:

The birds fed the 133 g/MT Xylamax diet and diets supplemented at the inclusion rate of 65 g/MT Xylamax diet had similar results in the trial. The following data is for birds fed the 65 g/MT Xylamax diet.

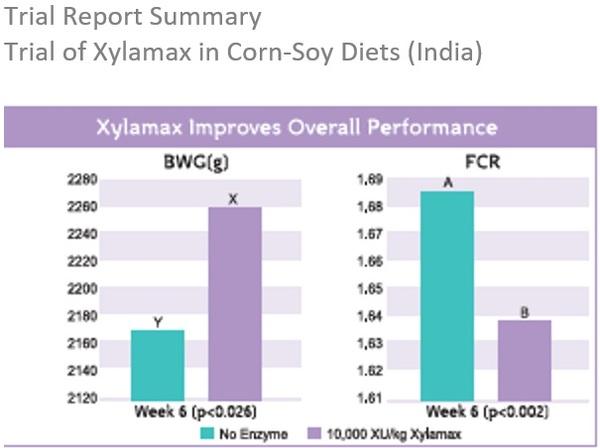

Overall Performance affected by Xylamax

Overall, birds fed Xylamax showed significantly higher BWG (p<0.026) and FCR (p<0.002). On average, BWG improved by 90 g and FCR improved by 5 points.

Overall Performance affected by Energy Level and Xylamax

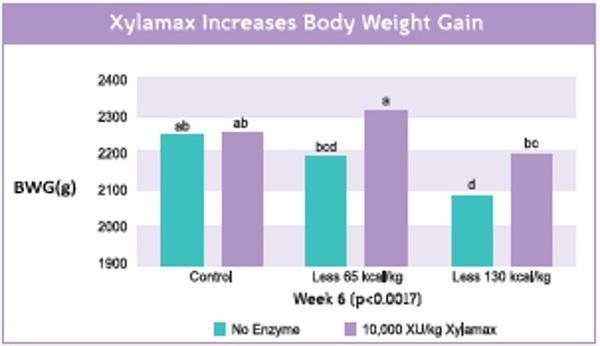

Body Weight Gain (BWG)

As expected, without supplementation of Xylamax the BWG decreases as the level of energy in the feed drops. There was almost a linear response to the diet energy levels with no Xylamax inclusion. With the supplementation of Xylamax in diets with decreased energy, the improved BWG to be similar to standard energy diets.

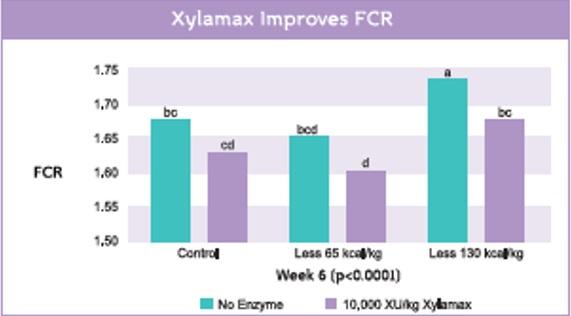

Feed Conversion Rate (FCR)

Adding Xylamax to diets regardless of the energy level provided an improvement in FCR. Maximizing feed cost savings by removing 130 kcal/kg of energy and then supplementing Xylamax to that diet yielded an FCR that was similar to the high energy diet with no Xylamax. By removing 65 kcal/kg at of energy and supplementing Xylamax provides a moderate level of feed cost savings but also showed an improvement in the FCR of those birds when compared to the un-supplemented, high-energy diet.

Conclusion:

Based on this trial, Xylamax works well in poultry production conditions and can be used in two ways:

Reformulation: Reduce dietary energy by 130 kcal/kg and supplement Xylamax at 65 g/MT of diet to maintain performance similar to standard dietary energy level.

On-top: Supplementing Xylamax at 65 g/MT of diet in the existing formulation improves FCR by at least 4 points.

Key Findings:

Birds fed diets supplemented with 65 g/MT Xylamax

- Demonstrated 4 to 6 points of FCR improvement

- Improved BWG by 5% to 7%

- Utilized 130 kcal/kg more energy than birds fed diets not containing Xylamax

Related topics:

Authors:

Influencers who recommended :

Sandra Rodrigues, Frank IveyRecommend

Comment

Share

15 de junio de 2021

Dr. S.V. Rama Rao¹, and the research team of the project, I congratulate the work carried out, where the treatments, the repetitions and the number of birds per experimental unit have been defined. As proposed, I suggest that in the discussion of the results, the positive effect of the enzyme on the possible improvement of the microbiota, resulting from the hydrolysis of PNA with the production of oligosaccharides, should also be considered. As the improvement of the microbiota also has a positive influence on the digestibility of nutrients, which contributes to increasing the energy available to the birds. And finally, due to the composition of the rations, wouldn't the use of the mannanase enzyme be interesting?

Recommend

Reply

30 de marzo de 2022

Xylanase enzyme in Poultry feed improves gut health and enhances flock productivity .

1. Xylans are the most prevalent type of NSP in poultry feed grains, representing up to 43% of the total NSP content.

2. Research confirms that 450-500 kcal/kg of valuable energy in a typical poultry diet is not digestible.

a) The addition of enzyme feed additives has been shown to make up to 30% (135 kcal/kg) of this energy digestible (Cowieson, 2010).

3. Xylanase enzymes hydrolyze glycosidic bonds in xylans that make up cell walls, resulting in the release of the encapsulated nutrients.

4. Feed enzyme appli- cation in diets for poultry is also one of the most researched fields in poultry science today, with over 2 500 independ- ent enzyme trials conducted with broilers alone (Rosen, 2010).

5. Energy is usually the most expensive nutritional component of poultry diets.

a) Therefore, a higher efficiency in its utilisation will result in lower feed cost.

6. Feed digestion occurs mainly in the small intestine of poultry (duodenum, jejunum, ileum) as evidenced by the amount of time the digesta material remains in these areas of the bird’s gut.

a) The majority of absorption of nutrients also occurs in the small intestine due to the presence of a higher number of villi, the site of nutrient absorption.

b) For any enzyme to deliver maximum results, it needs to work optimally at the 5.7-7.0 pH range occurring in the small intestine (Sturkie, 2000).

c) In the field of nutrition and food technology, the most significant aspects will be the use of enzymes, the evaluation of non-nutritional factors, which may maximise ingredient utilisation by the birds.

7. Enzymes will be increasingly used,

a) as they improve ingredient digestibility and nutrient absorption (Cowan et al., 1996),

b) as well as reduce the detrimental effects of anti-nutritional factors, thereby allowing higher flexibility in the use of feedstuffs as well as reducing feed costs (Ferket, 2009)

c) and pollutant excretion in animal waste (Penz-Jr and Bruno, 2010).

d) In addition enzymes lowers feed costs, this will also reduce nitrogen excretion in the environment (Nahm, 2002).

8. A highly viscous composition of the digested material in the bird’s intestine causes a decrease in the passage rate through the gastrointestinal tract.

a) As a result, nutrient diffusion and absorption in the foregut is reduced, and unabsorbed nutrients are allowed to enter the hindgut where they facilitate the proliferation of detrimental bacteria.

b) High digesta viscosity further impairs poultry nutrition by reducing feed intake.

9. Xylanase improves gut health in poultry and is a Energy Booster and has ability to improve digestibility of plant-based feed ingredients and to reduce digesta viscosity is well-accepted.

a) Xylanase appear to be partially related to their indirect impact on mucosal morphology of the small intestine of birds.

10. In the intestine, undigested NSPs, including arabinoxylans, stimulate the proliferation of pathogenic bacteria

a) Xylanase reduces nutrient availability for cecal pathogens

and it not only reduces digesta viscosity through the hydrolysis of soluble arabinoxylans in the small intestine;

11. This process can also improve gut health by generating xylo-oligosaccharides (XOS), which are fermented, particularly in the foregut.

a) These have a prebiotic effect that selectively stimulates the growth of beneficial gram-positive bacteria in the foregut .

b) This greater level of beneficial microbial activity and growth in turn boosts production of volatile fatty acids, which can then be absorbed and utilised by the animal as an energy source.

12. Xylanase reduces oxidative stress in the gut and It reduces mucin secretion.

a) Mucin is an excellent nutrient source for some pathogenic bacteria such as E. coli and Clostridium perfringens.

b) Necrotic Enteritis, characterized by Clostridium perfringens, costs the global poultry industry about $2 billion annually (Ducatelle and Immerseel, 2010).

c) Necrotic Enteritis causes necrotic lesions in the intestinal tract, poor digestion, reduced weight gain, increased FCR, and even death.

13. Xylanase significantly reduces wet litter.

a) Xylanase improves laying performance in layers , Breeders and boosts energy in Broilers.

14. Xylanase improves flock uniformity and also reduces the impact on feedstuff variability.

To maximize release of encapsulated nutrients in feed grains, the correct type of xylanase enzyme is required.

15 XylaOpt of ABTL is a Themostable Xylanase enzyme feed additive which minimizes gut viscocity and reduce wet litter.

16. XylaOpt enhances significantly laying performance of Layers , Breeders and Broilers.

a) The recommended inclusion levels of XylaOpt is 100 gms to 150 gms / ton of feed .

Recommend

Reply

Would you like to discuss another topic? Create a new post to engage with experts in the community.