Introduction

Barley ranks fourth in global cereal production after corn, wheat and rice. About 65% of the world’s barley produced is fed to animals, including poultry.

Australia is a significant global producer of barley, ranking in the top five countries with about 5% of global production and is among the top three barley exporters accounting for about 30% of malt and 20% of feed barley trade. Australia is a reliable supplier of two row spring barley that is suitable for a wide range of malting, brewing and animal feed applications. Australian barley production averages about 8 million metric tonne (Mmt) per year, comprised of about 5.5 Mmt of feed and 2.5 Mmt of malt grades. Typically, about 1.3 Mmt of the feed barley is consumed domestically and 4.2 Mmt exported.

Nutritional attributes of Australian feed barley for layers

The two most important nutritional attributes of grains for accurate feed formulation and value assessment for layers are metabolisable energy (ME) and protein, or more specifically, digestible essential amino acids from the protein (standardised ileal digestible or ‘SID’).

The chemical composition and energy content of Australian grains, including barley was surveyed extensively under the ‘Premium Grains for Livestock Program’ (PGLP). NIR calibrations were developed from PGLP data, now commercialised internationally as ‘AusScan’.

Starch

As with other cereals, starch is the main component of, and contributor to ME in barley grain. Barley has a lower starch content than corn and wheat. The starch content of Australian feed barley typically ranges from about 49 to 56% as-fed. Starch levels have been shown to vary from season to season and region to region. Reasons for variation include variety, soil type, fertiliser application, rainfall (yield) and general growing conditions. Low starch (possibly as low as 40%) and hence lower ME barley is usually associated with frosted and drought-affected crops. Australian research reported feed barley with high screenings did not have lower starch and ME than barley with low screenings.

Fibre

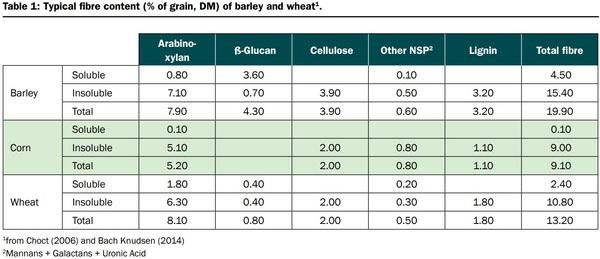

Non-starch polysaccharides (NSP) are the most significant fibre components of grains. Barley has a higher fibre content (NSP plus lignin),

both soluble and insoluble than corn and wheat (Table 1).

Soluble NSP are anti-nutritional in poultry diets because of their ability to absorb water and increase viscosity of digesta (gut contents). Barley, wheat and rye, the ‘viscous grains’ have high levels of soluble NSP in contrast to non-viscous grains such as corn and sorghum. The predominant soluble NSP are β-glucans in barley and arabinoxylans in wheat. However, barley soluble arabinoxylan content is significant.

Starch, β-glucans and cellulose are all glucose polymers but with different glucose linkages that affect solubility and hydrolysis by digestive enzymes. Glucose linkages are α-1,4 with α-1,6 side branches in starch, β-1,4 in cellulose and both β-1,3 and β-1,4 in barley β-glucans. Other NSP, such as arabinoxylans contain sugars other than glucose. β-glucans in yeast cell walls are recognised as immunemodulating. However, yeast β-glucans have β-1,3 linkages with β-1,6 side branches, different to the β-1,3 and β-1,4 linkages of barley. The immune-modulating effects of barley β-glucans in poultry have not been studied adequately.

The insoluble fibre content of barley is higher than corn and wheat because most barley, including Australian feed barley, has a hull, unlike ‘naked’ grains such as corn, wheat and sorghum. Insoluble fibre is nutritionally inert and does not contribute to ME. However, as a source of structural fibre, it is important for gut development and health. Studies show insoluble fibre in layer diets reduces the incidence of feather pecking and barley has higher levels than corn and wheat.

Enzymes

Although β-glucans are the major soluble NSP in barley, arabinoxylans are significant. The adverse effects of soluble NSP in barley are reduced or eliminated by β-glucanase and xylanase enzymes. β-glucanase products used in many barley studies also have xylanase activity as well and may explain inconsistent responses to β-glucanase. Adult birds seem to tolerate β-glucans well, with no performance improvements reported in many studies. However, water consumption increases, resulting in wetter manure and more dirty eggs. To alleviate these problems, β-glucanase is commonly added to layer feeds, often at lower levels than in broiler feeds.

Metabolisable energy (ME)

Most barley ME determinations have used test diets without enzymes, fed to growing broilers. 2,750 kcal/kg as-fed is the most common ME book value. Limited studies comparing the same samples of barley generally report higher ME without enzymes for adult cockerels (intact and caecectomised) and hens than for broilers. This is presumed to be due to differences in the ability of young and mature digestive tracts to handle digesta viscosity. When enzymes are included, ME differences are smaller (i.e. the ME enzyme response is greater with young than old birds).

Barley extract viscosity has been shown to decrease, and ME increase for typically 3 to 4 months after harvest, due to endogenous enzyme activity during storage. However, time after harvest is probably not pertinent to laying hens, or to Asian markets because barley exported from Australia would have matured by the time it was used.

Studies indicate an appropriate average ME value of Australian feed barley for laying hens is 2,850 kcal/ kg as-fed without enzymes and 2,900 kcal/kg as-fed with enzymes.

Protein/amino acids

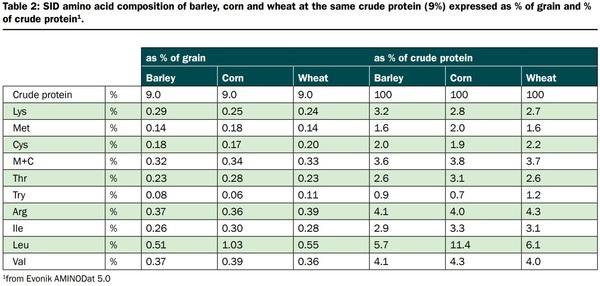

Barley typically contains more protein than corn, 2% or more, but less than wheat. Australian feed barley protein averages about 10% as-fed, range typically 8 to 12% as fed. Barley, corn and wheat protein differ in amino acid composition (amino acid as % of crude protein). The amino acid composition of a grain type is not a constant ratio to protein and in general, the essential amino acid content decreases as the protein content increases (AMINODat 5.0).

Protein digestibility of all cereal grains is high but digestibility coefficients reported for barley are lower than for corn and wheat. Differences between barley, corn and wheat are mainly due to the anti-nutritional effects of soluble NSP in barley and wheat. There is considerable evidence that feed enzymes increase digestibility and

reduce, if not eliminate digestibility differences between corn and viscous grains such as barley and wheat. Barley at 9% crude protein is lower in (AMINODat 5.0) SID methionine, M+C, threonine, isoleucine, leucine and valine than 9% corn but higher in lysine and tryptophan (Table 2). Other SID essential amino acids are similar. However, barley with its typically 2% higher crude protein than corn contributes more of all SID essential amino acids except for methionine and leucine. The SID leucine: isoleucine ratio of barley protein (about 2:1) is closer to ‘ideal’ (< 1.6:1) than that of corn protein (3.4:1).

Oil / linoleic acid

The oil and linoleic acid content of barley is a little higher than wheat but lower than corn. Even in high barley layer feeds, linoleic acid levels would be above 1%, sufficient to meet requirement.

Vitamins and minerals

Differences in vitamin and mineral content between barley, corn and wheat are minor and commercially irrelevant. Barley has a similar phytic acid content to corn and wheat.

Pigments

The carotenoid pigments present in yellow corn are absent in barley as in wheat. If barley replaces corn, pigments sources may need to be included to meet market requirements for yolk colour.

Pigment sources include corn gluten meal, corn DDGS, natural products (marigold and capsicum extracts) and synthetic products (apo-ester and canthaxanthin).

Mycotoxins

Australian grains, including feed barley are recognised as low mycotoxin because of dry conditions at harvest and good storage post-harvest.

Processing

Barley is suitable for, and commonly included in mash feeds for layers. Large particle size from coarse grinding or rolling is desirable for palatability and digestive function.

Gelatinisation temperature of starch is lower in barley (52-60ºC) than corn (62-72ºC) and even wheat (58-64ºC). Digesta viscosity was reported to be increased by steam cooking of barley and steam pelleting is likely to do the same.

Feeding whole grain to poultry has been a common practice for at least 30 years. Wheat is the grain most commonly fed as whole grain but barley is also fed whole to commercial layers.

Breeders

Barley is a suitable grain for all classes of poultry including broiler and layer breeders. Australian feed barley is known to have low mycotoxin contamination and may be less risky than locally produced corn for breeders.

Practical application - value and opportunity

Barley is a proven, reliable grain for commercial layer feeds. In Spain, UK, Australia and elsewhere, barley is commonly included at above 30% in commercial layer feeds, occasionally as high as 60%. Australian feed barley is an opportunity worthy of consideration in the region. Barley has high soluble NSP content (β-glucans and arabinoxylans) but at low inclusion levels in layer feeds, enzyme addition is not necessary. At moderate to high inclusion levels, enzymes (β-glucanase and maybe xylanase) should be added to reduce manure moisture and the incidence of dirty eggs, and maybe improve performance. The high insoluble fibre content of barley may reduce feather pecking and improve gut health.

*Dr Tim Walker (timwalkerau@gmail.com) is a nutritionist consultant based in Australia. References are available from the author. The support of the Australian Export Grain Innovation Centre (AEGIC)