Explore all the information on

Feed mills

Welcome to the page about Feed mills of Engormix; a source of knowledge on Feed mills.

Jürgen Joachim, Managing Director at Graf Equipment, gave a presentation on pellet mills, dies, rolls and their performance, during FIGAP 2016, in Guadalajara, Mexico....

Comments : 3

Recommendations: 1

On Engormix's Spanish speaking community a great discussion has been originated a few months ago and is covering the experiences in the use of a pellet mill having 2 or 3 roll assemblies. A few manufacturer names came into the picture as CPM and Andritz being the most popular. A great debate between available surface area in the pelleting chamber verse pellet mill capacity has been created and there are some good comments/experiences from either end users or equipment manufacturers. It is my...

Comments : 1

Recommendations: 2

...

Comments : 1

Recommendations: 0

Josef Barbi , President of E.S.E. Intec talks about the equipment that they will be manufacturing from IDAH, in order to provide this machinery for customers in United States, Latinamerica, Europe, Africa and Middle East markets....

Comments : 2

Recommendations: 0

Dr. Blake Wilson (Adisseo) commented on the quality of ingredients and the value of networking in this Swine It interview with host Laura Greiner. ...

Comments : 0

Recommendations: 0

"You cannot improve what you do not control. You cannot control what you do not measure. You cannot measure what you do not define". (anonymous) It is very difficult to know where to begin a discussion about feed mill efficiency. Perhaps a good place to start would be a definition of efficiency. The Encarta Dictionary: English (North America) defines efficiency as 1. Competence, the ability to do something well or achieve a desired...

Comments : 7

Recommendations: 1

Even though this machinery has improved greatly over the centuries, modern cleaning and milling actually takes longer than ancient forms of flour making. Stone mills were in use for centuries and flour was principally a food for the wealthy. However, in the late 1800s, huge improvements in industry and the creation of the roller mill made it possible for nearly everyone to integrate flour into their diet without trouble. Modern technology takes a bit longer to prepare the flour because it is...

Comments : 0

Recommendations: 0

Poultry feed production

Seventy percent of broiler feed in Pakistan is produced in modern feedmills equipped with pelleting technology. Small feedmillers volume of business has been squeezed and in future may become non-profitable due to small volumes and higher cost of raw materials. Poultry feed production over the past 10 years is shown in tables 1 and 3. Table 1. Poultry feed production (000 tonnes)

...

Comments : 3

Recommendations: 2

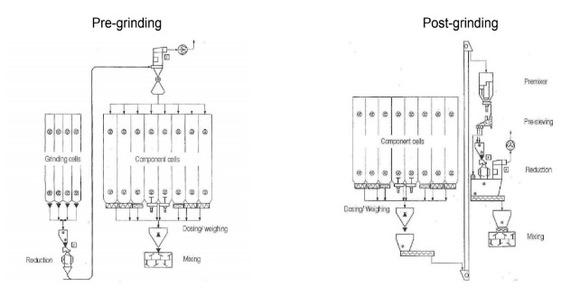

Post-grinding can be defined as the grinding step after all the ingredients of the feed are mixed just before the mash enter the pre-conditioner for steam/water injection. It has been done initially on the Pet Food and Aquafeed industries but now it has become...

Comments : 2

Recommendations: 3

Among the various stages of the pelleting process, grinding is one of those that consume more energy, but it’s essential for pelletizing because it allows to create a homogeneous mixing and to reduce the volumes. In fact, in the compound-feed production process 60% of the total energy consumption is used for pelleting, 16% for milling, 14% for conveying, 7% for receiving, 2% for mixing and 1% for delivery. Particle size reduction is the first step in the feed manufacturing process and,...

Comments : 9

Recommendations: 1

Introduction As particle size research has continued to evolve, so has the nutritionist’s understanding of what is needed to optimize animal performance. There is a push to begin manufacturing diets of specific particle sizes to account for differences among species and growth phases. This may appear to be a relatively easy task for the feed mill; however, as the grinding limitations of the feed mill are exposed, it becomes more difficult to find a resolution...

Comments : 2

Recommendations: 0

Ingredients come to the feed processor from a variety of sources. Many of these, particularly the coarse cereal grains, require some degree of processing before they are ready to be blended into an animal ration. The process of particle size reduction improves ingredient performance during mixing and, in most cases, the nutritive value of an ingredient can be improved or more nearly realized. There are many ways to reduce the particle size of feed ingredients. Two of the most common...

Comments : 0

Recommendations: 6

Dr P. E Vijay Anand from the U.S. Soybean Export Council speaks abou how we can make aquaculture feed milling better in the future, especially in the coming three or four years at the 2nd Global Milling Conference Programme, India 2014....

Comments : 3

Recommendations: 1

Hello everyone. We hope you are well. I would like to know if any of you have documented the procedure or recommendation for adjusting the average particle diameter at the outlet of a roller or hammer mill. At Farmonitoring Agrotech (startup) we are developing the image processing granulometry method, which can obtain average size in 3 minutes. We have obtained differences of less than 30 microns with respect to the normal sieving method. What we want to improve now is the adjustment or...

Comments : 0

Recommendations: 0

Dear all, Any idea how can we increase production output (rate) of pellet mill considering non variable motor (fixed)? Common low rate those have dairy (high grains) type. Thanks. ...

Comments : 0

Recommendations: 0

Feed manufacturers are often forced by circumstances to focus on short-term concerns such as: How many tonnes were produced this week, how many customers do I have, or how much down time did I have this week? While important, short-term problems can cause manufacturers to focus on solving problems rather than pursuing the company’s mission. Manufacturers who regularly examine their company’s mission tend to have a sense of who they are and where they are going. How many feed...

Comments : 2

Recommendations: 0

An optimal grinding requires the right amount of intake of air, which is cleaned in the nozzle filters. This also guarantees an economic use of the hammer mill. The air is necessary to quickly transport the fine product from the area of the hammers through the grinding sieve and, at the same time, to cool the product. By the ventilator, mounted in front of the filter a vacuum is generated and the air is sucked into the air inlet funnel of the hammer mill infeed device,...

Comments : 0

Recommendations: 0

DES MOINES, Iowa, May 24, 2018 /PRNewswire/ -- Kemin Industries, a global nutritional ingredient company that uses science to touch more than 3.8 billion people every day with its products and services, has launched a rebranding of its liquid programmes for the Kemin Animal Nutrition and Health business in order to better address unique solutions for Kemin customer needs.

For several decades, Kemin has had a strong focus on offering liquid solutions for different...

Comments : 0

Recommendations: 0

Todd Applegate (University of Georgia) spoke on the effects of whole corn on ileal and cecal microbiota, as well as the importance of collaborative work in today's poultry industry, during IPPE 2018 in Atlanta, USA....

Comments : 1

Recommendations: 6

There are two key reasons for high-energy consumption, low throughput and a rise in temperature of ground materials coming from a hammer mill. They are: 1. Poor hammer milling capacity Large amounts of colliding energy is wasted as heat due to the high rate of eccentric collision. This only makes materials spin and bounce around in grinding chamber, and does not lead to further size reduction. 2. Poor screening capacity ...

Comments : 4

Recommendations: 0

.jpg&w=3840&q=75)