Natural betaine as an effective rumen modulator

Published: April 6, 2021

By: Ana Gavrau, Global Technical Product Manager, AGRANA Sales & Marketing GmbH

Considering the livestock production, natural betaine plays a key role in the metabolism of monogastric animals. However, the role of betaine in ruminants and the rumen activity is underexplored until now.

Therefore, AGRANA invested in a research project to study the effect of natural betaine on the rumen activity.

In collaboration with the University of Veterinary Medicine, Vienna a recent study in vitro was carried out.

The aim was to test natural betaine as a possible effective rumen modulator under normal physiological and stressed rumen conditions. Liquid betaine with 40% betaine content (AcitBeet® L) was used as a natural source of betaine. The research work revealed new insights and scientific connections, which are briefly summarized below.

Ruminants are dependent upon ruminal microbes that enable the formation of short-chain fatty acids (SCFAs) and microbial protein synthesis by fermenting feedstuffs. SCFAs and microbial proteins are the main source of energy and protein in ruminants. Therefore, proper fermentation in ruminants is crucial and climatic and dietary shifts can suppress fermentation. Rumen osmolality and temperature are important physicochemical parameters that impact fermentation by affecting the activity, survival and balance of the ruminal microbial population.

It has been shown, that high-concentrate feeding, especially in high-yielding cows, elevates the temperature and osmolality of the rumen content. It is assumed that osmotic pressure influences the voluntary dry matter intake. As a result of such physicochemical changes, the metabolism and growth of ruminal microbes are placed under thermal and hyperosmotic stress. Depending on the severity, this can compromise the stability of the rumen ecosystem and thus animal health, and ultimately the farmer’s revenue.

Not only climatic stress, but also feeding with a high proportion of grain, can lead to a number of physiological challenges in cattle. The composition of the diet is the largest determining factor for the microbial stability of the rumen and therefore it is of greatest importance for rumen fermentation. The modulating potential of the active ingredients in the rumen via the diet, is a promising way to improve ruminal fermentation and to ensure the required energy supply.

Actibeet® natural betaine as potential rumen modulator

Natural betaine, as a non-ionic osmolyte and a methyl group donor is well studied and successfully used in the feed of monogastric animals. Betaine is a proven nutritional aid against heat and osmotic stress. As an excellent organic osmolyte, betaine protects the enzymatic and cellular integrity and functionality. Furthermore as a methyl group donor, betaine provides methyl groups for synthesis of numerous substances, as an intermediate product in protein and energy metabolism. Betaine is also used very efficiently in industrial fermentation processes in order to increase the output of the final product (vitamins or aminoacids). The above mentioned characteristics make betaine suitable to normalise microbial cell physiology, perturbed during heat and osmotic stress.

In ruminants, microbial metabolism of natural betaine is known, but the extent to which ruminal microbes use betaine has been underexplored. Microorganisms can use betaine as an osmolyte to adapt to external stressors and as a potential methyl group donor. Because of these properties, betaine could modulate ruminal fermentation. Therefore, it might be more significant to ruminal microbes during stress than previously thought.

In collaboration with the team of Professor Qendrim Zebeli from the University of Veterinary Medicine Vienna, Austria, in vitro study was carried out recently.This study aimed to test natural betaine from ActiBeet® L as a possible effective rumen modulator under normal physiological and stressed rumen conditions.

Methods

A rumen simulation technique (RUSITEC) was used to evaluate the effects of betaine supplementation on rumen fermentation variables, microbiome and nutrient digestibility under normal, heat-stressed and hyperosmotic-stressed rumen conditions. The basal diets were high in non-fibre carbohydrates, representing a common diet for high-yielding dairy cattle. ActiBeet® L with a betaine content of 40%, was used as a natural betaine source. Three different betaine doses of betaine from ActiBeet® L were used: 0% (control), 0.3% of diet dry matter (low), and 1.7% of diet dry matter (high). Each dose was tested under two incubation temperatures: normal rumen and heat-stressed rumen temperature and two osmotic conditions, including normal rumen osmolality and hyperosmotic conditions. The osmolarity and pH-value of incubation fluid for normal and hyperosmotic conditions were successfully determined through the amount of concentrate in the diet and modified buffer. There were six runs in total, each run included the adaptation and measurement periods to determine fermentation characteristics. All trial data were analysed by the MIXED procedure of SAS.

Short-chain fatty acids gains with betaine addition

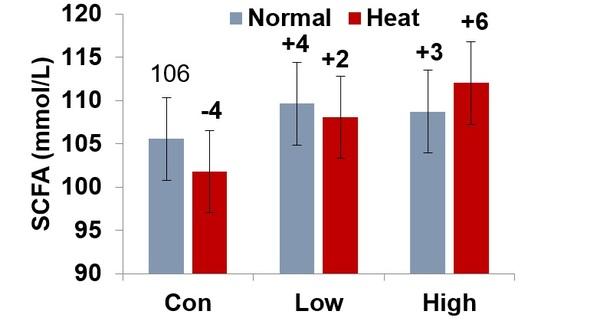

The major finding was, that betaine supplementation increased the concentration of short-chain fatty acids (SCFAs) in heat-stressed rumen conditions (Figure 1):

Figure 1. The concentration of total SCFAs in incubation fluid (mmol/l)

SCFAs are a major source of energy in ruminants providing up to 75% of the metabolizable energy. Without betaine, the heat-stressed condition clearly decreased the SCFA concentration, which indicates that heat stress leads to a depression in milk production. The negative effect of heat stress on suppressed SCFA concentration disappeared when betaine was supplemented to the ration and the concentration of the SCFAs increased linearly with betaine dosage. From our data, the biggest difference on SCFA between treatments, was +10 mmol/L (High dose vs. Control), both under heat stressed rumen condition (Figure 1a).

Considering a rumen capacity of 100 L, the increased level would be equal to 1000 mmol/d, therefore more SCFA available for maintenance and production. From this point of view, our data suggest that betaine can support the milk production during heat stress.

Considering a rumen capacity of 100 L, the increased level would be equal to 1000 mmol/d, therefore more SCFA available for maintenance and production. From this point of view, our data suggest that betaine can support the milk production during heat stress.

More propionate under hyperosmotic rumen conditions

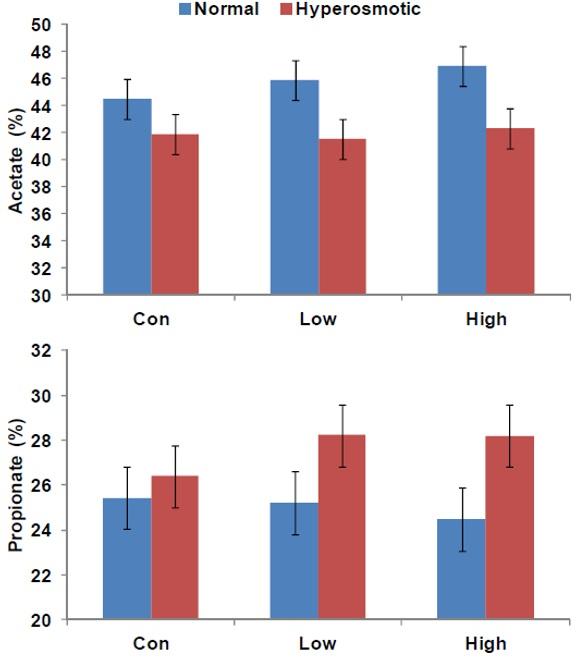

Under the normal rumen condition betaine is converted to acetate, which is the building block for milk fat synthesis. Under the hyperosmotic rumen condition, betaine shifted the SCFA towards more propionate.

The addition of betaine in high dose leads to an increased propionate proportion, resulting in a pronounced decrease in acetate: propionate ratio (Figure 2):

The addition of betaine in high dose leads to an increased propionate proportion, resulting in a pronounced decrease in acetate: propionate ratio (Figure 2):

Figure 2. The proportion of acetate and propionate (mol/100 mol) as affected by betaine supplementation and osmotic‐stressed rumen conditions.

Propionate is an important glucogenic precursor in ruminants and is used for lactose production, which is a key determinant for milk yield. Therefore, the results suggest that betaine could be used to promote energy supply from propionate and increase hepatic gluconeogenesis in times of osmotic‐stressed rumen conditions.

For practical purpose

The in vitro dosage, (tested for grain-rich diets for high yielding dairy cattle), after factor correction, can be translated into the following practical dose:

6 g of betaine /cow / d, as practical low dose;

36 g of betaine / cow / d, as practical high dose.

For the optimum betaine dose rate the interaction between diet, productivity, climatic conditions (temperature and humidity) must be considered.

Conclusion

Hyperthermal and hyperosmotic stress are typical stressors caused by feeding, as well as a high ambient temperature. Both stress conditions can lead to poor fermentation and subsequently adverse effects on ruminant productivity. According to our data, heat and hyperosmotic stress clearly suppresses rumen fermentation and natural betaine promotes microbial fermentation activity, making it an effective rumen modulator.

Betaine supplemented to grain-rich diets enhances microbial fermentation leading to more SCFA production during heat stress and it minimizes the effect of hyperosmotic stress by decreasing the acetate to propionate ratio. The increase in propionate percentage upon betaine addition under the hyperosmotic stress suggests, that betaine supports fermentation by means of dominating microbes.

Under normal physiological condition betaine is converted in the rumen to acetate, which is the building block for milk fat synthesis. Under hyperosmotic rumen condition in this trial, betaine shifted the SCFA towards more propionate. Propionate is the most important glucogenic precursor required for lactose synthesis and is responsible for milk yield. From this point of view, our data suggest that betaine can support the milk production during heat and hyperosmotic stress.

Betaine, as a substrate and methyl donor for microbes directly modulates ruminal fermentation and as a compatible osmolyte betaine can enable microbial tolerance to stressors.

The rumen microbes may take a full benefit of available betaine and use it against thermal and hyperosmotic stress in a way that helps to maintain their fermentation activities, crucial for ruminant health and productivity.

The rumen microbes may take a full benefit of available betaine and use it against thermal and hyperosmotic stress in a way that helps to maintain their fermentation activities, crucial for ruminant health and productivity.

ActiBeet® natural source of betaine

Actibeet® L - a liquid, natural betaine was introduced by AGRANA in the animal feed sector in 2015.

With the new crystallization facillity, AGRANA is expanding its product portfolio by natural crystalline betaine: ActiBeet® 96 and ActiBeet® 97.

Natural betaine is only produced in three plants worldwide. The construction of the new betaine crystallisation plant, which is located next to the sugar refinery in Tulln on the Danube in Austria, more exactly in Lower Austria, was just completed last summer. In addition to the traditional sugar production, molasses has been desugarized for many years in Tulln, where sugar beet syrup is obtained all year round from the raw material molasses. One of the co-products - liquid betaine - is the raw material for the betaine crystallization system. This manufacturing facility is operated as a joint venture between AGRANA and US based company - The Amalgamated Sugar Company (TASCO). TASCO is the global leader in the technology for extracting high-quality crystalline betaine from sugar beet molasses. The construction of the crystallization plant took exactly one year. The financing of the new plant, entailed the investment of around € 40 million. The new plant has a production capacity of around 8,500 metric tons of crystalline betaine per year.

In order to meet customer requirements, investments were made not only in the crystallization system, but also in the storage capacity of the raw material, the bottling facility and an elevated warehouse. In addition to betaine for the feed and fertilizer sector, Beta Pura GmbH also produces betaine for the food and personal care sector. Due to high product value and the ongoing trend of consumer preference for natural products and strictly tested quality, make ActiBeet® the smart betaine choice and suitable for the global market.

References

References are available on request: ana.gavrau@agrana.com

Definitions

Osmolality: osmoles of solute per kilogram of solvent (Osm/kg)

Osmolarity: osmoles of solute per liter of solution (Osm/L)

Related topics:

Authors:

AGRANA GROUP

Recommend

Comment

Share

Would you like to discuss another topic? Create a new post to engage with experts in the community.

.jpg&w=3840&q=75)