Carcass characteristics and organ weights of broiler chickens fed varying inclusion levels of cassava (Manihot esculenta Crantz) peel products-based diets

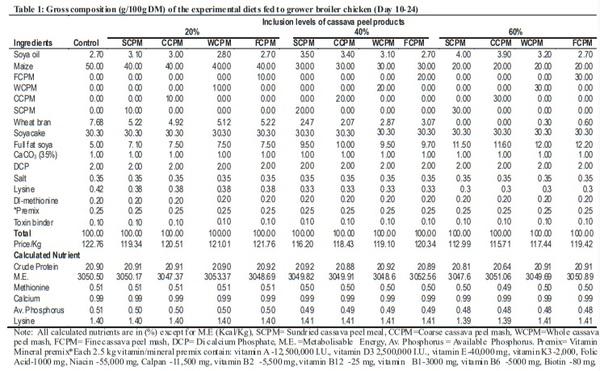

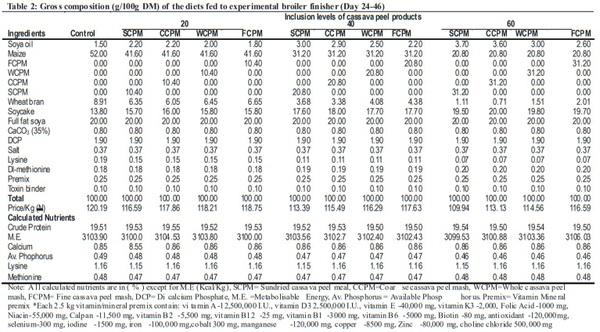

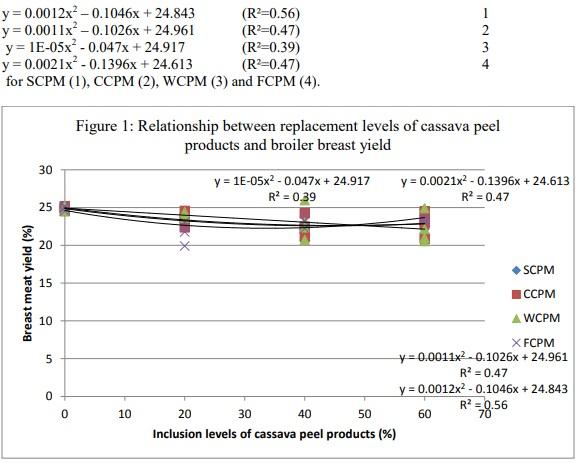

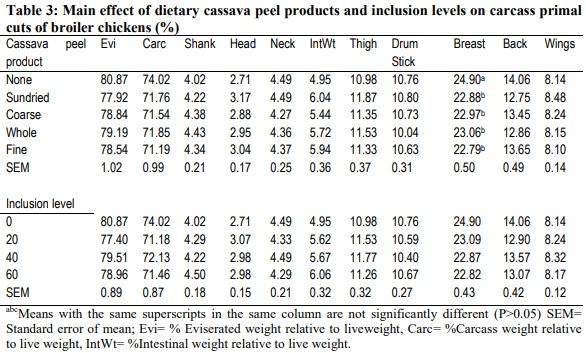

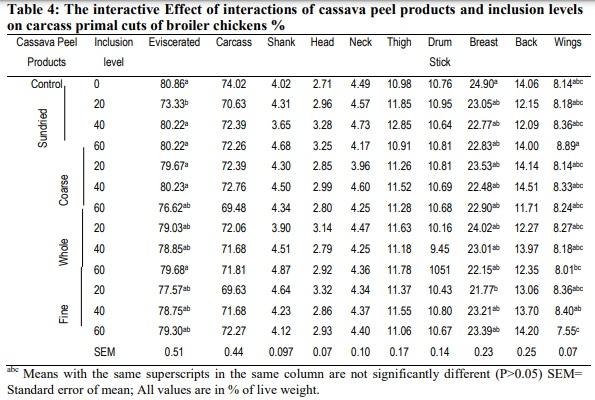

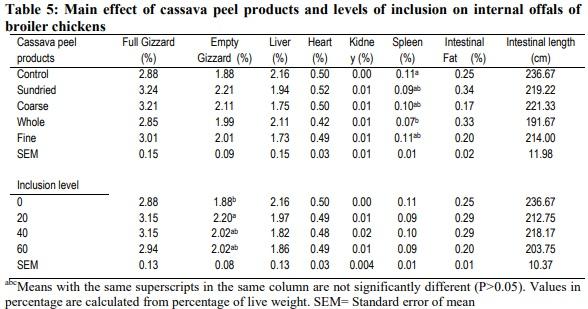

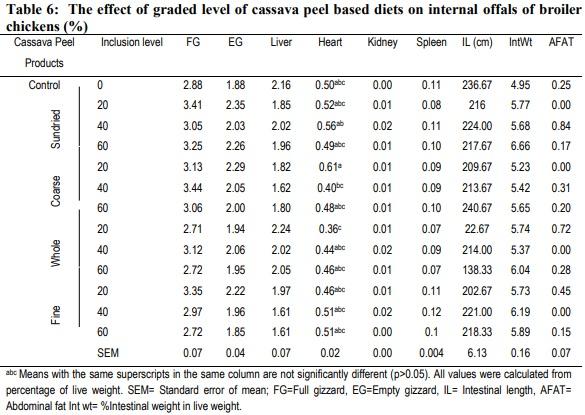

The effect of feeding four cassava peel products-based diets on carcass characteristics and organ weights of broiler chickens were investigated with 455, 10-day old Ross 308 broiler chickens randomly divided into thirteen groups of 35 birds each. Each group was replicated five times and a replicate comprised seven chicks. The design was 1+ (4 x 3) augmented factorial arrangement in a completely randomized design. The experimental diets were sundried cassava peel meal (SCPM), coarse cassava peel mash (CCPM), whole cassava peel mash (WCPM) and fine cassava peel mash (FCPM) each at three dietary inclusion levels to replace maize at 20, 40 and 60%, while the control diet was a maize-based diet. The diets were fed ad libitum to the respective grower (10-24 days) and finisher (25-46 days) experimental chickens. Results showed no significant effect (p>0.05) of feeding chickens with cassava peel-based diets on carcass primal cuts and internal offals except breast meat and spleen. Breast meat yield (24.90%) of chicks on maize-based diet was significantly higher (p<0.05) than others. Effect of interaction of cassava peel products and inclusion levels on eviscerated weight and breast weight was significant (p<0.05). The eviscerated weight (80.86%) and breast meat yield (24.90%) of chickens on control were higher (p<0.05). In conclusion, replacement of up to 60% dietary maize with cassava peel products had similar effect on broiler carcass yield and productivity but breast yield. Also, further processing of WCPM to FCPM and CCPM did not confer any advantage on chick productivity.

1. Nworgu, F. C., Egbunike, G. N. and

Ogundola, F. I. (2000). Performance and nitrogen utilization of broilers fed full fat extruded soybean meal and full fat soybean. Tropical Animal Production

Investigation. 2000; 3:47–54.

2. Ogunwole, O. A., Lawal, H. O., Idowu, A.

I., Oladimeji, S. O., Abayomi, F. D., and

Tewe, O. O. (2016). Carcass characteristics, proximate composition and residual retinol in meat of broiler chickens fed β-carotene cassava (Manihot Esculenta

Crantz) grits based diets. Journal of

Oladimeji et al

156

Animal Production Research; 28(2):102-

117. ISSN 0189-0514.

3. Oyebimpe, K., A. O. Fanimo, O. O.

Oduguwa and W. O. Biobaku (2006).

Response of broiler chickens to cassava peel and maize offal in cashew nut mealbased diets. Archivos de Zootecnia. 55 (211): 301-304.

4. Tewe, O. (1983). Thyroid cassava toxicity in animals. Pages 114-118 in Cassava toxicity and thyroid: research and public health issues. Proceedings, International

Workshop on Cassava Toxicity, edited by

F. Delange and R Ahluwalia, 31 May-2

June 1982, Ottawa, Canada. IDRC-207e:

Ottawa

5. Adeyemo, I. A. and Sani, A. (2013).

Haematological parametres and serum biochemical indices ofbroiler chickens fed

Aspergillus niger hydrolyzed cassava peel meal based diet. IJRRAS 15 (3) J u n e 2 0

1 3 www.arpapress.com/Volumes/Vol

15Issue3/IJRRAS_15_3_24.pdf

6. Abu, O. A., Olaleru, I. F., Oke, T. D.,

Adepegba,V. A. and Usman, B. (2015)

Performance of broiler chicken fed diets containing cassava peel and leaf meals as replacements for maize and soya bean meal. International Journal of Science and

Technology, 4 (4), 169-173.

7. Okike I., A. Samireddypalle, L.Kaptoge,

C. Fauquet, J. Atehnkeng,

R.Bandyopadhyay, P.Kulakow, A.

Duncan, T. Alabi, and M. Blummel. (2015). Technical innovations for smallscale producers and households to process wet cassava peels into high-quality animal feed ingredients andaflasafe™ substrate.

Food chain 5(1-2):71-90. Practical Action

Publishing, 2015, www.practicalactionpublishing.org. http://dx.doi.org/10.3362/2046-

1887.2015.005, ISSN: 2046-1879 (print)

2046-1887 (online)

8. El-Waseif, M. A. and Gabal M. S. A. (2017). Carcass traits, cuts yield, raw meat quality and burger quality characteristics of different marketing ages and sex broiler chickens. Egyptian Journal of Food

Science. 45 (2017):17-28.

9. Omode, A. A., E. U. Ahiwe, Z. Y. Zhu, F.

Fru-Nji and P. A. Iji (2018). Improving cassava quality for poultry feeding through application of biotechnology. In: Cassava.

Published by Intech. Retrieved from http://dx.doi.org/10.5772/intechopen.7223

6.

10. Zhai W., Araujo L., Burgess, S. C. and

Corzo A. (2012). Protein expression in pectoral skeletal muscle of chickens as influenced by dietary methionine. Poultry

Science 91:2548–2555. doi: 10.3382/ps.2012-02213.

11. Egbunike, G. N., E.A. Agiang, A.O.

Owosibo and A.A. Fatufe (2009). Effect of protein on performance and haematology of broilers fed cassava peel-based diets.

Archivos de zootecnia. Vol. 58 (224), 655-

662.

12. Diarra S. S., Sandakabatu, Perera, D.,

Tabuaciri, P. and Mohammed U. (2014).

Growth performance, carcass measurements and organ weight of broiler chickens fed cassava copra meal-based or commercial finisher diets in Samoa. Asian

Journal of Poultry Science. 8(1):16-22.

13. John, J. L. (1994). The avian spleen: A neglected organ. The Quarterly Review of

Biology. 69(3):327

14. Rathgeber B. M., Budgell K. L., Maclsaac

J. L., Mirza M. A., and K. L Doncaster (2008). Growth performance and spleen and bursa weight of broilers fed yeast betaglucan. Canadian Journal of Animal

Science. 88:469-473.

15. Platel, K. and Srinivasan K. (2004).

Digestive stimulant action of spices: A myth or reality? Indian Journal of

Veterinary Research. 119:167-179.

16. Aguilar, C. A. L., Lima K. R., Manno, M.

C., Maia J. G. S., Fernandes Neto, D. L.,

Tavares, F. B., Roque T. J. L. R.,

Mendonca R. C. A. and Carmo, E. S. N. (2014). Rosewood (Aniba rosaeodora

Ducke) oil in broiler chickens diet. Revista

Brasileira de Saude e Producao Animal.

15(1):108-119.

17. Obun C. O. (2008). Performance,

Digestibilility and carcass and organ weights of finisher broiler chicks fed graded levels of fermented locust bean (Parkia biglobosa) seed meal. Asian

Journal of Poultry Science. 2:17-23.

18. Amerah A. M., V. Ravindran, R. G.

Lentle, and D. G. Thomas (2008).

Influence of particle size on performance, energy utilization, digestive tract development, and digesta parameters of broiler starters fed wheat- and corn-based diets. Poultry Science. 87:2320-2328. doi:10.3382/ps.2008-00149

.jpg&w=3840&q=75)