INTRODUCTION

Aspergillus flavus, A. parasiticus, A. nominus and a few other Aspergilli which produce aflatoxins (AFs) are closely related omnipresent microfungi that contaminate seeds and plant debris of many crops in the field during harvest, storage, and processing (Cvetnic & Pepeljnjak, 2007).

Aflatoxins are a group of carcinogenic my cotoxins causing various acute and chronic intoxications in humans and animals in addition to causing liver cancer. Dietary exposure to aflatoxins and human aflatoxicosis in the developing countries is extensively reviewed (Williams et al., 2004). Aflatoxins have immunotoxic, mutagenic and carcinogenic effects, and they were classified as group 1 carcinogenes in 1993 by the International Agency for research of Cancer. Aflatoxin B1 is the most frequently encountered of the group and the most toxic (Ghali et al., 2008; Matic et al., 2008).

In the recent years, many dietary strategies involving microorganisms have been under investigation. Many species of bacteria and fungi have been shown to enzymatically degrade mycotoxins (Ciegler et al., 1966; Bata & Lasztity, 1999). Saccharomyces cerevisiae has been utilized in food fermentation for several centuries. In the African and Asian countries, fermentation is used as a predominant mode of food processing and preservation. Many yeast species, especially S. cerevisiae, play a predominant role in food fermentation along with lactic acid bacteria (Jespersen, 2003).

Mycotoxin binding by S. cerevisiae and lactic acid bacteria has been reviewed recently (Shetty & Jespersen, 2006). Cell wall of S. cerevisiae consists of network of β-1,3 glucan back bone with β-1,6 glucan side chains, which is in turn attached to highly glycosylated mannoproteins which make the external layer (Kollar et al., 1997). The proteins and glucans provide numerous easily accessible binding sites with different binding mechanisms such as hydrogen bonding, ionic or hydrophobic interactions (Huwig et al., 2001, 1). Binding of different mycotoxins such as aflatoxin, ochratoxin and zearalenone to yeast cell surface has been reported earlier and the binding has been attributed to cell wall glucans in case of ochratoxin and zearalenone (Raju & Devegowda, 2000; Bejaoui et al., 2004; Yiannikouris et al., 2004, 1). However, there are no systematic studies on individual strains of S. cerevisiae binding aflatoxin.

Kusumaningtyas et al. (2006) reported that aflatoxin B1 contaminations in feed were reduced by S. cerevisiae addition.

Feeding of S. cerevisiae to poultry showed beneficial effects against aflatoxin-induced toxicities (Stanley et al., 1993). When dried yeast and yeast cell walls were added to ration along with aflatoxin B1, a significant reduction in the toxicity was observed (Santin et al., 2003; Baptista et al., 2004).

The aim of this study was to investigate influence of baker's yeast in two different concentrations on the production of the aflatoxin B1 by Aspergillus flavus.

MATERIALS AND METHODS

Mould

Three isolates of Aspergillus flavus that showed ability to produce aflatoxin B1 in high concentrations (2400, 1800 and 1300 μg.kg-1) were used for investigation. Aflatoxigenic nature of these isolates was confirmed by VICAM's AflaTest during the earlier examinations (Šaric & Škrinjar, 2007). Isolates were maintained on Sabouraud Maltose Agar (Merck, Germany) at 4 °C. Manual prepared yeast extract-sucrose (YES) broth served as aflatoxin production medium.

Baker's Yeast

The commercial baker's yeast (Saccharomyces cerevisiae) collected from different shops in Novi Sad was activated in 100 ml of Sabouraud maltose broth. The next step after the incubation period (48 h, 25 °C) was determination of cell number using the hemocytometer chamber. Working concentrations of yeast cells suspension in sterile physiological saline were 109 and 106 per one ml.

Influence of two concentrations of yeast cells suspension on three isolates of Aspergillus flavus was investigated. Three controls without addding of baker's yeast were also prepared.

Measurement of aflatoxin B1

Erlenmeyer flasks containing 100 ml of YES broth were inoculated with 5 ml of fungal spores suspension (108 spores.ml-1) and with 1 ml of yeast cells suspension at appropriate concentrations (109.ml-1 and 106.ml-1). Spore population was counted using a standard Koch method. The flasks were then incubated at 25 ± 2 °C for 12 days in an incubator shaker. Aflatoxin B1 measurement was determined at the end of the incubation period by VICAM's AflaTest (Vicam, 1999).

AflaTest from VICAM is the trusted aflatoxin test that produces precise numerical results (Vicam, 1999). Using monoclonal affinity chromatography, AflaTest can isolate aflatoxins B1, B2, G1, and G2 from feeds, foods and grains at levels as low as 0.1 ppb. Results may be recorded using digital fluorometer readout with automatic printing devices (Vicam, 1999). AOAC es-tablished reliability and assurance of the Afla test (AOAC, 1995).

RESULTS AND DISCUSSION

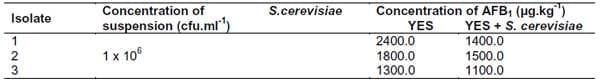

Table 1. The production of aflatoxin B1 (AFB1) by Aspergillus flavus in YES broth with S. cerevisiae cells suspension in concentration of 1 x 106 cfu.ml-1

Results in table 1. show that in comparison to the control the addition of S. cerevisiae suspension in concentration of 1 x 106 cfu.ml-1 decreases production of AFB1 by isolate 1 for 41.6% and by isolate 2 for 16.6%. In the case of isolate 3, aflatoxin production was reduced for 15.4%.

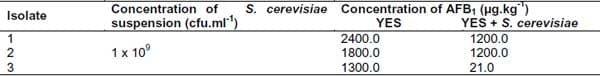

Table 2. The production of aflatoxin B1 (AFB1) by Aspergillus flavus in YES broth with S. cerevisiae cells suspension in concentration of 1 x 109 cfu.ml-1

Results in table 2. shows that in comparison to the control the addition of S. cerevisiae suspension in concentration of 1 x 109 cfu.ml-1 decreases production of AFB1 by isolate 1 for 50.0 and by isolate 2 for 33.3%. In the case of isolate 3, aflatoxin production was reduced for 98.4%.

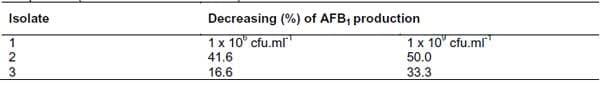

Table 3. Decreasing (%) of aflatoxin B1 (AFB1) production using different concentrations of S. cerevisiae cells suspension (1 x 106 and 1 x 109 cfu.ml-1)

As can be seen from table 3 the higher concentration of S. cerevisiae cells suspension showed stronger, but different effect on the production of AFB1 by three investigated isolates of A. flavus.

The different production of AFB1 by three isolates of A. flavus under the same conditions is consequence of distinction in genetic predisposition of these three isolates. The different reduction of the AFB1 content, except by genetic diversity of three isolates of A. flavus, could be explained by competition for nutrient sources between A. flavus and S. cerevisiae and by different ability of three examinated isolates to adapt to the same conditions in YES broth.

CONCLUSION

The obtained results show that the commercial baker′s yeast (Saccharomyces cerevisiae) reduced production of AFB1 by all investigated isolates of A. flavus. Since the higher concentration of S. cerevisiae cell suspension showed stronger effect on reduction of AFB1 content, it can be concluded that AFB1 reduction depend on concentration of baker′s yeast. Regarding the obtained results of preliminary examinations, further investigations should be undertaken in order to established a relationsheep between antimycotoxigenic activity and characteristic of cell wall of used species of S. cerevisiae. It also should be examine a production of biomass of these three A. flavus isolates in the medium with present of various con-centrations of S. cerevisiae cell suspen-sion.

ACKNOWLEDGMENTS

This work is a part of the Project (TR – 20068) supported by the Ministry of Science and Technological Development, Republic of Serbia.

REFERENCES

AOAC Official Methods of Analysis (1995). Natural toxins. In: Scott PM (ed), AOAC Inter-national, Virginia, Arlington.

Baptista, A.S., Horii, J., Calori-Domingues, M.A., Gloria, E.M., Salgado, J.M., Vizioli, M.R. (2004). The capacity of manno-oligosaccharides, ther-molysed yeast and active yeast to attenuate aflatoxicosis. World Journal of Microbiology and Biotechnology, 20, 474–481.

Bata A. & Lasztity, R. (1999). Detoxification of mycotoxin contaminated food and feed by micro-organisms. Trends in Food Science and Te-chnology, 10, 223–228.

Bejaoui, H., Mathieu, F., Taillandier, P., Lebrihi, A. (2004). Ochratoxin A removal in synthetic and natural grape juices by selected oenological Sa-ccharomyces strains. Journal of Applied Micro-biology, 97, 1038–1044.

Ciegler, A., Lillehoj, E.B., Peterson, R.E., Hall, H.H. (1996). Microbial detoxification of aflatoxin. Applied Microbiology, 14, 934–939.

Cvetnic, Z. & Pepeljnjak S. (2007). Interactions between aflatoxin B1 producer and other moulds. Arh Hig Rada Tokiskol, 58, 429-434.

Ghali, R., Hmaissia-khlifa, K., Ghorbel, H., Maaroufi, K., Hedili, A. (2008). Incidence of aflatoxins, ochratoxin A and zearalenone in tunisian food. Food Control, 19, 921-924.

Huwig, S., Freimund, O., Kappeli, Dutler, H. (2001). Mycotoxin detoxication of animal feed by different adsorbents. Toxicology Letters, 122, 179–188.

Jespersen, L. (2003). Occurrence and taxono-mic characteristics of strains of Saccharomyces cerevisiae predominant in African indigenous fermented foods and beverages. FEMS Yeast Research, 3, 191–200.

Kollar, R., Reinhold, B.B., Petrakova, E., Yeh, H.J., Ashwell, G., Drgonova, J., Kapteyn, Klis, J.C., Cabib, E. (1997). Archi-tecture of the yeast cell wall. Beta 1,6-glucan interconnects manno-protein, beta 1,3-glucan, and chitin. Journal of Biological Chemistry, 272, 17762–17775.

Kusumaningtyas, E., Widiastuti, R., Maryam, R. (2006). Reduction of aflatoxin B1 in chicken feed by using Saccharomyces cerevisiae, Rhi-zopus oligosporus and their combination. Myco-pathologia, 162, (4), 307.

Matic, J., Mandic, A., Mastilovic, J., Mišan, A., Beljkaš, B., Milovanovic I. (2008). Contamina-tions of raw materials and food products with mycotoxins in Serbia. Food Processing, Quality & Safety, 35, (2), 65-70.

Prathapkumar, H. S., Benedicte, H., Jespersen, L. (2007). Surface binding of afla-toxin B1 by Saccharomyces cerevisiae strains with potential decontaminating abilities in indigenous fermen-ted foods. International Journal of Food Micro-biology, 113, (1), 41-46.

Raju, M.V.L.N. & Devegowda, G. (2000). Influence of esterified-glucomannan on perfor-mance and organ morphology, serum bio-chemistry and haematology in broilers exposed to individual and com-bined mycotoxicosis (afla-toxin, ochratoxin and T-2 toxin). British Poultry Science, 41, 640–650.

Santin, E., Paulilo, A.C., Maiorka, A., Na-kaghi, L.S.O., Macan, M., Silva, A.V.F., Alessi, C.A. (2003). Evaluation of the efficiency of Saccha-romyces cerevisiae cell wall to ameliorate the toxic effects of aflatoxin in broilers. International Journal of Poultry Sciences, 2, 241–344.

Shetty, P.H. & Jespersen, L. (2006). Saccha-romyces cerevisiae and lactic acid bacteria as potential mycotoxin decontaminating agents. Trends in Food Science and Technology, 17, 48–55.

Stanley, V.G., Ojo, R., Woldensenbet, S., Hu-tchinson, D.H. (1993). The use of Saccharo-myces cerevisiae to suppress the effects of aflatoxins in broiler chicks. Poultry, 72, 1867–1872.

Vicam (1999). Aflatest Instruction Manual. Wa-tertown-USA, pp 76.

Williams, J.H., Phillips, T.D., Jolly, P.E., Stiles, J.K., Jolly, C.M., Aggarwal, D. (2004). Human aflatoxicosis in developing countries: a review of toxicology, exposure, potential health conse-quences, and interventions. American Journal of Clinical Nutrition, 80, 1106–1122.

Yiannikouris, J., Francois, L., Poughon, C.G., Dussap, G., Bertin, G., Jeminet, Jouany, J.P. (2004). Adsorption of zearalenone by beta-D-glucans in the Saccharo-myces cerevisiae cell wall. Journal of Food Protection, 67, 1195–1200.

Šaric Lj., Marija Škrinjar: Proizvodnja afla-tok-sina B1 od strane plesni izolovanih iz zacina koji se koriste u industriji mesa. Medunarodno 54. savetovanje industrije mesa. Zbornik kratkih sa-držaja. 129. s. Vrnjacka Banja. 18–20. juna 2007.