Predictive microbiology and machine learning by optimization productive process: Metanalysis

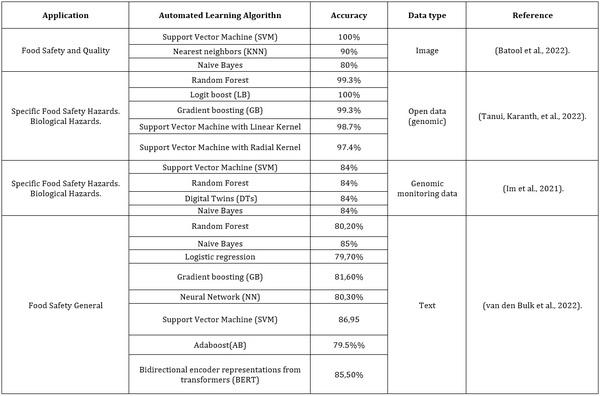

Batool, A., Ganguli, S., Almashaqbeh, H. A., Shafiq, M., Vallikannu, A. L., Sankaran, K. S., Ray, S., & Sammy, F. (2022). An IoT and Machine Learning-Based Model to Monitor Perishable Food towards Improving Food Safety and Quality. Journal of Food Quality, 2022. https://doi.org/10.1155/2022/6302331

Beck, K. L., Haiminen, N., Chambliss, D., Edlund, S., Kunitomi, M., Huang, B. C., Kong, N., Ganesan, B., Baker, R., Markwell, P., Kawas, B., Davis, M., Prill, R. J., Krishnareddy, H., Seabolt, E., Marlowe, C. H., Pierre, S., Quintanar, A., Parida, L., … Weimer, B. C. (2021). Monitoring the microbiome for food safety and quality using deep shotgun sequencing. Npj Science of Food, 5(1). https://doi.org/10.1038/s41538-020-00083-y

Buyrukoğlu, S. (2021). New hybrid data mining model for prediction of Salmonella presence in agricultural waters based on ensemble feature selection and machine learning algorithms. Journal of Food Safety, 41(4). https://doi.org/10.1111/jfs.12903

Cammarota, G., Ianiro, G., Ahern, A., Carbone, C., Temko, A., Claesson, M. J., Gasbarrini, A., & Tortora, G. (2020). Gut microbiome, big data and machine learning to promote precision medicine for cancer. NATURE REVIEWS GASTROENTEROLOGY & HEPATOLOGY, 17(10), 635–648. https://doi.org/10.1038/s41575-020-0327-3

Chaix, E., Couvert, O., Guillaume, C., Gontard, N., & Guillard, V. (2015). Predictive Microbiology Coupled with Gas (O2/CO2) Transfer in Food/Packaging Systems: How to Develop an Efficient Decision Support Tool for Food Packaging Dimensioning. Comprehensive Reviews in Food Science and Food Safety, 14(1), 1–21. https://doi.org/10.1111/1541-4337.12117

Batool, A., Ganguli, S., Almashaqbeh, H. A., Shafiq, M., Vallikannu, A. L., Sankaran, K. S., Ray, S., & Sammy, F. (2022). An IoT and Machine Learning-Based Model to Monitor Perishable Food towards Improving Food Safety and Quality. Journal of Food Quality, 2022. https://doi.org/10.1155/2022/6302331

Beck, K. L., Haiminen, N., Chambliss, D., Edlund, S., Kunitomi, M., Huang, B. C., Kong, N., Ganesan, B., Baker, R., Markwell, P., Kawas, B., Davis, M., Prill, R. J., Krishnareddy, H., Seabolt, E., Marlowe, C. H., Pierre, S., Quintanar, A., Parida, L., … Weimer, B. C. (2021). Monitoring the microbiome for food safety and quality using deep shotgun sequencing. Npj Science of Food, 5(1). https://doi.org/10.1038/s41538-020-00083-y

Buyrukoğlu, S. (2021). New hybrid data mining model for prediction of Salmonella presence in agricultural waters based on ensemble feature selection and machine learning algorithms. Journal of Food Safety, 41(4). https://doi.org/10.1111/jfs.12903

Cammarota, G., Ianiro, G., Ahern, A., Carbone, C., Temko, A., Claesson, M. J., Gasbarrini, A., & Tortora, G. (2020). Gut microbiome, big data and machine learning to promote precision medicine for cancer. NATURE REVIEWS GASTROENTEROLOGY & HEPATOLOGY, 17(10), 635–648. https://doi.org/10.1038/s41575-020-0327-3

Chaix, E., Couvert, O., Guillaume, C., Gontard, N., & Guillard, V. (2015). Predictive Microbiology Coupled with Gas (O2/CO2) Transfer in Food/Packaging Systems: How to Develop an Efficient Decision Support Tool for Food Packaging Dimensioning. Comprehensive Reviews in Food Science and Food Safety, 14(1), 1–21. https://doi.org/10.1111/1541-4337.12117

Committee on the Review of the Use of Scientific Criteria and Performance Standards for Safe Food., & Institute of Medicine (U.S.). (2003). Scientific criteria to ensure safe food. National Academies Press.

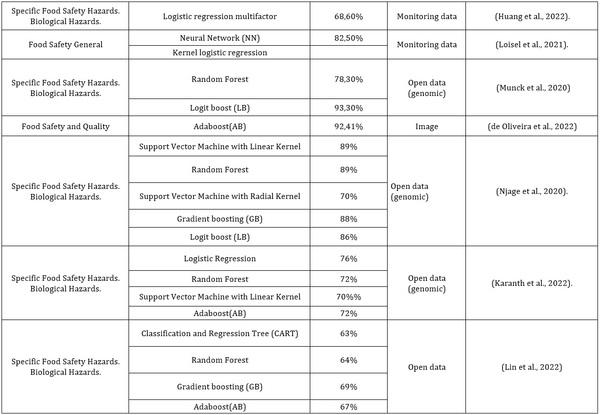

de Oliveira, A. N., Bolognini, S. R. F., Navarro, L. C., Delafiori, J., Sales, G. M., de Oliveira, D. N., & Catharino, R. R. (2022). Tomato classification using mass spectrometry-machine learning technique: A food safety-enhancing platform. Food Chemistry, 398. https://doi.org/10.1016/j.foodchem.2022.133870

Fratamico, P. M., Bhunia, A. K., & Smith, J. L. (James L. ). (2005). Foodborne pathogens : microbiology and molecular biology. Caister Academic Press.

Garcia, S. N., Osburn, B. I., & Cullor, J. S. (2019). A one health perspective on dairy production and dairy food safety. In One Health (Vol. 7). Elsevier B.V. https://doi.org/10.1016/j.onehlt.2019.100086

Golden, C. E., Rothrock, M. J., & Mishra, A. (2019). Using Farm Practice Variables as Predictors of Listeria spp. Prevalence in Pastured Poultry Farms. Frontiers in Sustainable Food Systems, 3. https://doi.org/10.3389/fsufs.2019.00015

Gonçalves-Tenório, A., Nunes Silva, B., Rodrigues, V., Cadavez, V., & Gonzales-Barron, U. (2018). Prevalence of pathogens in poultry meat: A meta-analysis of European published surveys. Foods, 7(5). https://doi.org/10.3390/foods7050069

González, S. C., Possas, A., Carrasco, E., Valero, A., Bolívar, A., Posada-Izquierdo, G. D., García-Gimeno, R. M., Zurera, G., & Pérez-Rodríguez, F. (2019). ‘MicroHibro’: A software tool for predictive microbiology and microbial risk assessment in foods. International Journal of Food Microbiology, 290, 226–236. https://doi.org/10.1016/j.ijfoodmicro.2018.10.007

Goodswen, S. J., Barratt, J. L. N., Kennedy, P. J., Kaufer, A., Calarco, L., & Ellis, J. T. (2021). Machine learning and applications in microbiology. In FEMS Microbiology Reviews (Vol. 45, Issue 5). Oxford University Press. https://doi.org/10.1093/femsre/fuab015

Greener, J. G., Kandathil, S. M., Moffat, L., & Jones, D. T. (2022). A guide to machine learning for biologists. In Nature Reviews Molecular Cell Biology (Vol. 23, Issue 1, pp. 40–55). Nature Research. https://doi.org/10.1038/s41580-021-00407-0

Hibbing, M. E., Fuqua, C., Parsek, M. R., & Peterson, S. B. (2010). Bacterial competition: Surviving and thriving in the microbial jungle. In Nature Reviews Microbiology (Vol. 8, Issue 1, pp. 15–25). https://doi.org/10.1038/nrmicro2259

Hiura, S., Koseki, S., & Koyama, K. (2021). Prediction of population behavior of Listeria monocytogenes in food using machine learning and a microbial growth and survival database. Scientific Reports, 11(1). https://doi.org/10.1038/s41598-021-90164-z

Huang, L., Jia, Z., & Hwang, C. A. (2022). Growth and No-Growth boundary of Listeria monocytogenes in beef – A logistic modeling. Food Research International, 152. https://doi.org/10.1016/j.foodres.2021.110919

Im, H., Hwang, S.-H., Kim, B. S., & Choi, S. H. (2021). Pathogenic potential assessment of the Shiga toxin-producing Escherichia coli by a source attribution-considered machine learning model. https://doi.org/10.1073/pnas.2018877118/-/DCSupplemental

Jiang, Y., Luo, J., Huang, D., Liu, Y., & Li, D. D. (2022). Machine Learning Advances in Microbiology: A Review of Methods and Applications. In Frontiers in Microbiology (Vol. 13). Frontiers Media S.A. https://doi.org/10.3389/fmicb.2022.925454

Kang, Z., Zhao, Y., Chen, L., Guo, Y., Mu, Q., & Wang, S. (2022). Advances in Machine Learning and Hyperspectral Imaging in the Food Supply Chain. In Food Engineering Reviews. Springer. https://doi.org/10.1007/s12393-022-09322-2

Karanth, S., Tanui, C. K., Meng, J., & Pradhan, A. K. (2022). Exploring the predictive capability of advanced machine learning in identifying severe disease phenotype in Salmonella enterica. Food Research International, 151. https://doi.org/10.1016/j.foodres.2021.110817

Koseki, S. (2016). Predictive Modeling for Estimation of Bacterial Behavior from Farm to Table. Food Safety, 4(2), 33–44. https://doi.org/10.14252/foodsafetyfscj.2016006

Koseki, S., Koyama, K., & Abe, H. (2021). Recent advances in predictive microbiology: theory and application of conversion from population dynamics to individual cell heterogeneity during inactivation process. In Current Opinion in Food Science (Vol. 39, pp. 60–67). Elsevier Ltd. https://doi.org/10.1016/j.cofs.2020.12.019

Koutsoumanis, K. P., Lianou, A., & Gougouli, M. (2016). Last developments in foodborne pathogens modeling. In Current Opinion in Food Science (Vol. 8, pp. 89–98). Elsevier Ltd. https://doi.org/10.1016/j.cofs.2016.04.006

Lin, Z., Qin, X., Li, J., Zohaib Aslam, M., Sun, T., Li, Z., Wang, X., & Dong, Q. (2022). Machine learning approach for predicting single cell lag time of Salmonella Enteritidis after heat and chlorine treatment. Food Research International, 156. https://doi.org/10.1016/j.foodres.2022.111132

Liu, Z., Mutukumira, A. N., & Chen, H. (2019). Food safety governance in China: From supervision to coregulation. Food Science and Nutrition, 7(12), 4127–4139. https://doi.org/10.1002/fsn3.1281

Loisel, J., Duret, S., Cornuéjols, A., Cagnon, D., Tardet, M., Derens-Bertheau, E., & Laguerre, O. (2021). Cold chain break detection and analysis: Can machine learning help? In Trends in Food Science and Technology (Vol. 112, pp. 391–399). Elsevier Ltd. https://doi.org/10.1016/j.tifs.2021.03.05

Ma, L. I., Kornacki, J. L., Zhang, G., Lin, C.-M., & Doyle, M. P. (2007). Development of Thermal Surrogate Microorganisms in Ground Beef for In-Plant Critical Control Point Validation Studies. In Journal of Food Protection (Vol. 70, Issue 4). http://meridian.allenpress.com/jfp/article-pdf/70/4/952/1678375/0362-028x-70_4_952.pdf

Mateo, E. M., Gómez, J. V., Tarazona, A., García-Esparza, M. Á., & Mateo, F. (2021). Comparative analysis of machine learning methods to predict growth of f. Sporotrichioides and production of t-2 and ht-2 toxins in treatments with ethylene-vinyl alcohol films containing pure components of essential oils. Toxins, 13(8). https://doi.org/10.3390/toxins13080545

Mcmeekin, T. A., Mellefont, L. A., & Ross, T. (2007). Predictive microbiology: Past, present and future. In Modelling Microorganisms in Food (pp. 7–21). Elsevier Ltd. https://doi.org/10.1533/9781845692940.1.7

Melnyk, K., Klus, S., Montavon, G., & Conrad, T. O. F. (2020). GraphKKE: graph Kernel Koopman embedding for human microbiome analysis. Applied Network Science, 5(1). https://doi.org/10.1007/s41109-020-00339-

Munck, N., Njage, P. M. K., Leekitcharoenphon, P., Litrup, E., & Hald, T. (2020). Application of Whole-Genome Sequences and Machine Learning in Source Attribution of Salmonella Typhimurium. Risk Analysis, 40(9), 1693–1705. https://doi.org/10.1111/risa.13510

Njage, P. M. K., Leekitcharoenphon, P., Hansen, L. T., Hendriksen, R. S., Faes, C., Aerts, M., & Hald, T. (2020). Quantitative microbial risk assessment based on whole genome sequencing data: Case of listeria monocytogenes. Microorganisms, 8(11), 1–24. https://doi.org/10.3390/microorganisms8111772

Pérez-Lavalle, L., Carrasco, E., & Valero, A. (2020). Microbiological criteria: Inestablishmentprinciplesfood qualityfor theirandandapplicationsafety. Italian Journal of Food Safety, 9(1). https://doi.org/10.4081/ijfs.2020.8543

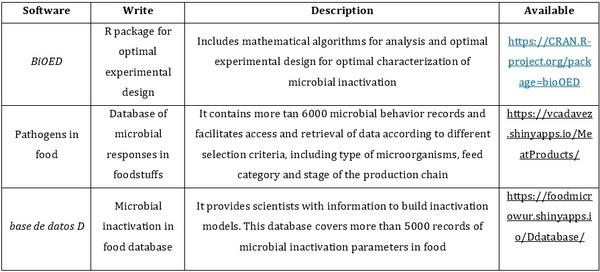

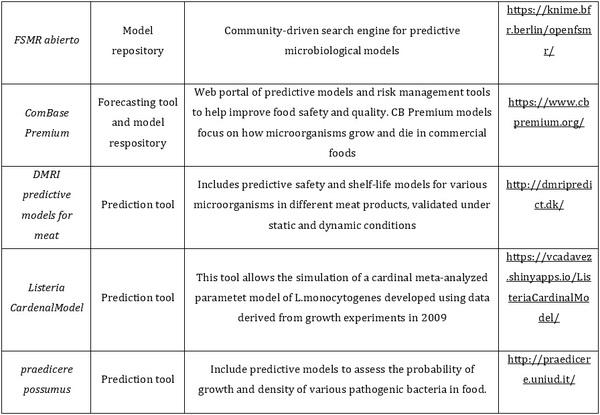

Possas, A., Valero, A., & Pérez-Rodríguez, F. (2022). New software solutions for microbiological food safety assessment and management. In Current Opinion in Food Science (Vol. 44). Elsevier Ltd. https://doi.org/10.1016/j.cofs.2022.100814

Sabater, C., Cobo-Díaz, J. F., Álvarez-Ordóñez, A., Ruas-Madiedo, P., Ruiz, L., & Margolles, A. (2021). Novel methods of microbiome analysis in the food industry. In International Microbiology (Vol. 24, Issue 4, pp. 593–605). Springer Science and Business Media Deutschland GmbH. https://doi.org/10.1007/s10123-021-00215-8

Sakowski, E., Uritskiy, G., Cooper, R., Gomes Maya and McLaren, M. R., Meisel, J. S., Mickol Rebecca L. and Mintz, C. D., Mongodin, E. F., Pop, M., Rahman, M. A., Sanchez, A., Timp, W., Vela, J. D., Wolz, C. M., Zackular, J. P., Chopyk, J., Commichaux, S., Davis, M., Dluzen, D., Ganesan, S. M., … Preheim, S. P. (2019). Current State of and Future Opportunities for Prediction in Microbiome Research: Report from the Mid-Atlantic Microbiome Meet-up in Baltimore on 9 January 2019. MSYSTEMS, 4(5). https://doi.org/10.1128/mSystems.00392-19

Sarker, I. H. (2021). Data Science and Analytics: An Overview from Data-Driven Smart Computing, Decision-Making and Applications Perspective. In SN Computer Science (Vol. 2, Issue 5). Springer. https://doi.org/10.1007/s42979-021-00765-8

Stavropoulou, E., & Bezirtzoglou, E. (2019). Predictive modeling of microbial behavior in food. In Foods (Vol. 8, Issue 12). MDPI Multidisciplinary Digital Publishing Institute. https://doi.org/10.3390/foods8120654

Tanui, C. K., Benefo, E. O., Karanth, S., & Pradhan, A. K. (2022). A Machine Learning Model for Food Source Attribution of Listeria monocytogenes. Pathogens, 11(6). https://doi.org/10.3390/pathogens11060691

Tanui, C. K., Karanth, S., Njage, P. M. K., Meng, J., & Pradhan, A. K. (2022). Machine learning-based predictive modeling to identify genotypic traits associated with Salmonella enterica disease endpoints in isolates from ground chicken. LWT, 154. https://doi.org/10.1016/j.lwt.2021.112701

van den Bulk, L. M., Bouzembrak, Y., Gavai, A., Liu, N., van den Heuvel, L. J., & Marvin, H. J. P. (2022). Automatic classification of literature in systematic reviews on food safety using machine learning. Current Research in Food Science, 5, 84–95. https://doi.org/10.1016/j.crfs.2021.12.010

Vega, N. M., Allison, K. R., Samuels, A. N., Klempner, M. S., & Collins, J. J. (2013). Salmonella typhimurium intercepts Escherichia coli signaling to enhance antibiotic tolerance. Proceedings of the National Academy of Sciences of the United States of America, 110(35), 14420–14425. https://doi.org/10.1073/pnas.1308085110

Wessels, K., Rip, D., & Gouws, P. (2021). Salmonella in chicken meat: Consumption, outbreaks, characteristics, current control methods and the potential of bacteriophage use. In Foods (Vol. 10, Issue 8). MDPI AG. https://doi.org/10.3390/foods10081742

Whon, T. W., Shin, N.-R., Kim, J. Y., & Roh, S. W. (2021). Omics in gut microbiome analysis. JOURNAL OF MICROBIOLOGY, 59(3), 292–297. https://doi.org/10.1007/s12275-021-1004-0

Zhao, Y., Federico, A., Faits, T., Manimaran, S., Segre, D., Monti, S., & Johnson, W. E. (2021). animalcules: interactive microbiome analytics and visualization in R. MICROBIOME, 9(1). https://doi.org/10.1186/s40168-021-01013-0

Hai this is Andrea Jenner, how are you I just read your article entitled “Predictive Microbiology and Machine Learning by Optimization Productive Process: Metanalysis” and I felt it was amazing, so I request you to send your new article for our journal PriMera Scientific Surgical Research and Practice (ISSN: 2836-0028).

Hoping for the positive response.

.jpg&w=3840&q=75)