Explore all the information on

Feed processing and manufacturing

Welcome to the page about Feed processing and manufacturing of Engormix; a source of knowledge on Feed processing and manufacturing.

Joe Moritz (West Virginia University) talked about pelleting, thermal processing and other relevant aspects of feed manufacturing, during the Multi-State Poultry Feeding and Nutrition Conference in Indianapolis, USA. ...

Comments : 2

Recommendations: 7

Anthony Quant (Kalmbach Feeds) talked about grinding, batching, pelleting and mixing, among other aspects of feed control, during the Multi-State Poultry Feeding and Nutrition Conference in Indianapolis, USA....

Comments : 5

Recommendations: 6

Hello, Any advice on cleaning procedure for pad mixers. Mixer has a small door and wont allow human access inside. Is the specific cleaning material I can fill the mixer with and keep mixer on for a while for cleaning? Mixer is 500 kg mixer for pelletizer. Thanks in advance. ...

Comments : 0

Recommendations: 0

What is the difference between the flat die and the ring die? 1. Feeding mode The flat die granule machine enters the pressing chamber vertically by the weight of the material itself, and can be uniformly fed. The ring die granule machine adopts forced feeding, high-speed rotary centrifugal distribution into the granulating chamber, and distributes the material through the scraper. Uneven material 2. The pressure is in the mold of the same diameter. The diameter of the flat-die pressure...

Comments : 0

Recommendations: 0

.jpg&w=3840&q=75)

Lifecycle data on the sustainability of rendered products

Suggested link

How to granulate the flat die machine? Where are the advantages? During the granulation process, the rotary hopper located in the upper part of the flat die granule spreads the material evenly on the surface of the die, and then the material is pressed into the die hole by the rotating pressure roller and extruded from the bottom. The rod-shaped feed extruded from the hole is cut into the required length by a cutting roll and then discharged through the discharge port. advantage: 1. Simple...

Comments : 0

Recommendations: 0

Grinding. Grinding must be carried out reasonably and fully before using the new flat die machine (or replacing a new set of abrasive tools). The grinding method of the test machine is: generally, 5 kg of bran, 5 kg of engine oil, and 25 kg of fine river sand are mixed and put into the machine, and the raw materials are put into normal production after repeated extrusion for nearly 60 minutes. The finished granules prepared by grinding have smooth surface, no cracks, no granules, internal...

Comments : 0

Recommendations: 0

Working principle and introduction of flat mold

How the pellet machine works (pressing powdered raw materials into cylindrical pellets) Based on the principle of circular motion, the template and pressure roller are specially treated with high-quality alloy steel. The spindle and flat die drive the pressure roller under the action of friction force. The material is gelatinized at high temperature between the pressure roller and the template, and the protein is coagulated and...

Comments : 0

Recommendations: 0

Peter Ferket (NC State University) explained the benefits of this specific encapsulating technique of vitamin and mineral premixes, during IPPE 2019 in Atlanta, USA....

Comments : 2

Recommendations: 6

.jpg&w=3840&q=75)

Lifecycle data on the sustainability of rendered products

Suggested link

I am having issue with jelly corn on the roller of the flakes, which is causing me to stop production and clean the roller to be able to continue production tempering corn 4 hours steam conditioning 30 min roller gap 0.3 mm mill capacity 5ton/hr. Any suggestions? ...

Comments : 13

Recommendations: 0

1. Introduction Starch and its derivatives are used as ingredients and it is the main component in bakery products. It is also added in low quantities as additives to improve the sensory characteristics of a large number of manufactured foods. The products resulting from the hydrolysis of starches (glucose syrup or maltose, maltodextrins) and isomerization (iso-glucose or fructose) are used in the industries of candy, sweets, chocolates, cakes, pastries, as...

Comments : 0

Recommendations: 1

The American Feed Industry Association and Feedstuffs are proud to announce four category winners for the 2018 Feed Facility of the Year (FFY) program. AFIA congratulates Famo Feeds of Freeport, Minn., as the winner of the commercial dry livestock feed plant category; Koch Foods of Morton, Miss., as the winner of the integrator category;...

Comments : 0

Recommendations: 0

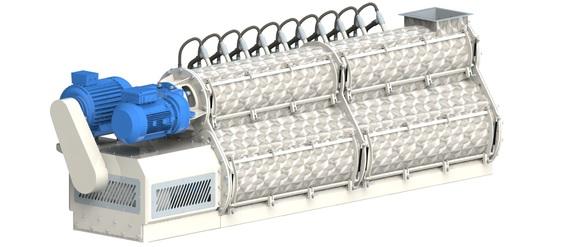

Conditioning is a process of hydrothermal treatment of powdery materials before pelleting of pellet feed. Domestic and foreign studies show that conditioning is one of the important factors affecting the quality of pellet feed, and it accounts for about 20% in the overall quality of pellet feed.

Learn more about #the role of conditioner in pellet feed processing# at: http://www.zhengchang.com/eng/index.aspx?cat_code=Zhengchang%20News...

Comments : 3

Recommendations: 0

.jpg&w=3840&q=75)

Lifecycle data on the sustainability of rendered products

Suggested link

COMPLETE OIL MILL PLANT DESIGN AND OPTIMIZATION ...

Comments : 7

Recommendations: 3

Dear sir In my plant, Andritz pellet mill 60 tph , the die was not freely rotate by hand when the machine was stopped,(The main bearing changed 3 months back, main motor amps normal, out put also good) Kindly gives your advice Arul Anand M ...

Comments : 1

Recommendations: 0

Eric Stibora, Director of Capital Sales at Anderson International Corp, highlights the main aspects of the press technology that this company based in the United States offers over the world, during IPPE 2018, in Atlanta, USA....

Comments : 4

Recommendations: 1

Does yeast pro ingredients expand pellet diameter? During compression process of pelleting, discharged pellet copied the shaped of the die hole pattern with relief....

Comments : 0

Recommendations: 0

.jpg&w=3840&q=75)

Lifecycle data on the sustainability of rendered products

Suggested link

Josef Barbi, president of E.S.E. & INTEC, speaks about the new Obial Silos created with metal Magneli and used in agriculture to store grain and cereals.

...

Comments : 1

Recommendations: 2

Pellets cost money, and good pellets cost more money. Operators are constantly challenged for maximizing production while improving product quality. Feed formulation, particle size, die selection, cooling, etc. can help them meet this challenge, but controlling the conditioning system is a pre-requisite for the production of quality pellets and optimizing production. The conditioning process is the most important component of any feed pelleting system, as far as pellet...

Comments : 14

Recommendations: 0

Amanda Cresanto, Responsible for The Expander Product Line at Anderson International Corp, describes the main improvements made to the Expander-Extruder-Cooker™, which is a pressure cooker designed to cook feed materials for improved digestibility and utilization in animals, during IPPE 2018, in Atlanta, USA....

Comments : 16

Recommendations: 1

Feed manufacturers are often forced by circumstances to focus on short-term concerns such as: How many tonnes were produced this week, how many customers do I have, or how much down time did I have this week? While important, short-term problems can cause manufacturers to focus on solving problems rather than pursuing the company’s mission. Manufacturers who regularly examine their company’s mission tend to have a sense of who they are and where they are going. How many feed...

Comments : 2

Recommendations: 0

.jpg&w=3840&q=75)