INTRODUCTION

Currently the potential impact of manure on the environment represents one of the world agriculture's major challenges. Once dominated by many small operations as part of traditional crop-livestock farms, livestock production has become highly concentrated in large operations. This development has separated animal production from crop production. Thus, the amount of manure produced often exceeds local demand for use as fertilizer.

When properly managed, manure can be used as a nutrient source for crops and to improve soil properties through accretion of soil organic matter. On the other hand, improperly managed manure can pose a threat to soil, water and air quality, and to human and animal health. Treatment technologies can play an important role in the management of livestock manure by providing a more flexible approach to land application and acreage limitations and by solving specific problems such as odors, pathogens, water pollution, ammonia emissions, greenhouse gas emissions, and phosphorus and heavy metal contamination of soils. Treatment can be enhanced with the use of biological, chemical, and physical methodologies, especially in combination as part of holistic systems that 1) are integrated with the needs of the land and other agri-food activities, and 2) maximize the value of manure through energy production, nutrient concentration and recycling, GHG reductions and environmental credits, and other beneficial by-products. The challenge for many countries is how to implement such technologies both on a wider scale and economically (Vanotti et al., 2009a).

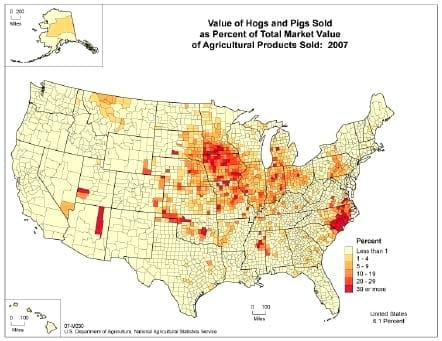

In the U.S., the structure of animal agriculture has changed significantly over the last two decades. Animal feeding operations are developed with larger number of animals concentrated in fewer farms. Between 1998 and 2009, the number of hog operations fell by about 60 percent, from 61,971 to 24,393, and the average inventory (hog sales and contract removals) per farm grew from 2,589 to 7,930 head (USDA, 2011). In 2007, the U.S. swine industry produced $18,000 million, an increase of 46% from 2002. Confined swine are generally concentrated in the Midwest and North Carolina (Figure 1). More than 50% of the total value of U.S. sales of hogs and pigs comes from three states: Iowa, North Carolina and Minnesota (USDA, 2007).

Figure 1: Value of hogs and pigs sold as percent of total market value of agricultural products (USDA, 2007)

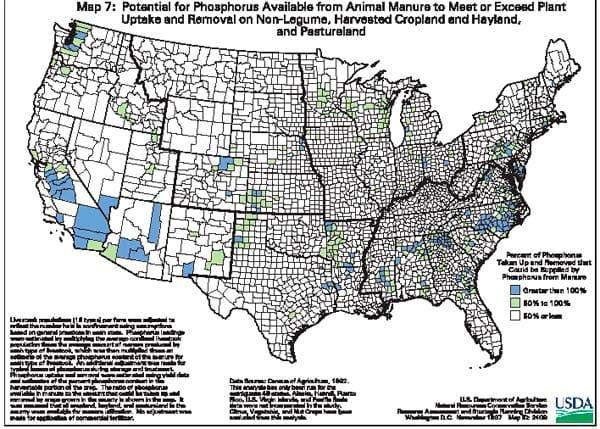

Over 1,100 million tons of livestock manure are generated in the U.S. annually containing 12,900 million pounds of nitrogen and 3,800 million pounds of phosphorus. About half of this is produced by livestock held in confinement. Consolidation of operations resulted in an increased volume of manure being produced on farms with less cropland per animal for utilization of the manure as plant fertilizer (USDA, 2011). Many areas produced more manure nutrients than available cropland can assimilate due to a net import of nutrients as feed (USDA, 2001). For example, Figure 2 shows the potential for phosphorus available from animal manure (includes hogs, cows, chickens and turkeys) to meet or exceed plant uptake and removal.

Figure 2. County level excess phosphorus from confined livestock production (USDA, 2001).

Site-specific, Comprehensive Nutrient Management Plans (CNMP) are being developed for all animal feeding operations (AFO) to minimize potential water pollutants from confinement facilities and land application of manure and organic by-products (USDA-NRCS, 2008). Using environmentally safe alternatives to land application of manure could be an integral part of the overall CNMP. These alternative uses are needed in areas where nutrient supply exceeds the nutrient requirements of crops, and/or where land application would cause significant environmental risk. More efficient and costeffective methods are needed for manure handling, treatment, and storage. Areas in need of targeting include (USDA-NRCS, 2008):

(1) Improved systems for solids removal from liquid manure;

(2) Improved manure handling, storage, and treatment methods to reduce ammonia volatilization;

(3) Treatment systems that transform and/or capture nutrients, trace elements, and pharmaceutically active compounds from manure;

(4) Improved composting and other manure stabilization techniques; and

(5) Treatment systems to remediate or replace anaerobic lagoons.

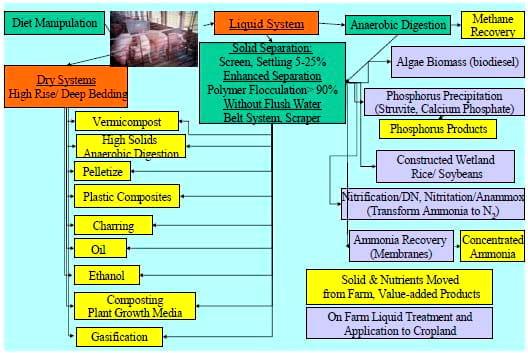

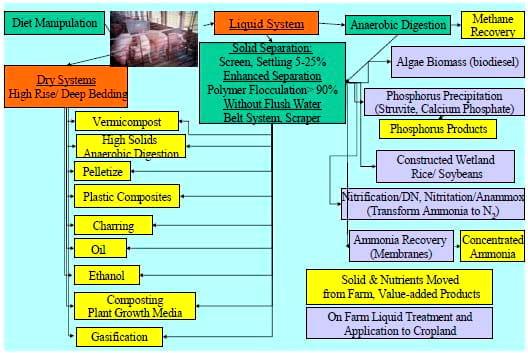

Figure 3: Alternative technologies for manure management.

Advanced treatment technologies are being developed to address manure problems in confined swine production (Figure 3). Some are in the research stage and others in the commercialization stage after years of extensive on-farm testing. The examples show a shift from municipal treatment methods in the near past to a new body of knowledge with methods adapted to the specific characteristics of these wastes and a different purpose for treatment. The flow diagram in Figure 3 illustrates three main alternative approaches to manure management. The first approach is to develop dry systems such as the deep bedding where fresh manure is mixed with a bulking agent or use inclined belts under the slatted floor to separate urine and solids so that all or part of the manure leaving a building is directly handled as a solid. The second approach is to improve or retrofit existing liquid systems so that volatile solids and organic nutrients are separated from the fresh manure and transported and/or treated with a variety of technologies to generate value-added products. Solid-liquid separation of the raw manure increases the capacity of decision making and opportunities for treatment. The separation up-front allows recovery of the organic compounds, which can be used for the manufacture of compost materials and other valueadded products or energy production. These products include stabilized peat substitutes, humus, bio-chars, organic fertilizers, soil amendments, and energy. The remaining liquid needs to be treated on the farm. A variety of biological, physical or chemical processes can be used to achieve specific nutrient management goals and environmental standards.

A third approach is to use anaerobic digesters (AD) to recover methane and energy from the carbon in the liquid manure (EPA, 2012). The biogas recovery systems collect methane from the manure and burn it to generate electricity or heat. Production of biogas from manure using anaerobic digesters is projected to be important worldwide. However, in areas of intensive livestock production, new technologies need to be developed in conjunction with AD to address surplus nitrogen and nitrogen removal and/or recovery of concentrated phosphorus from AD effluents in a form that can be removed from the watershed.

In addition to nutrients (e.g., nitrogen and phosphorus), manure and wastewater from animal feeding operations have the potential to contribute other pollutants such as organic matter, sediments, pathogens, heavy metals, and ammonia to the environment. The remainder of this paper will address development of manure treatment technologies that could be part of the basis for such solutions.

ENVIRONMENTAL SUPERIOR TECHNOLOGY

Anaerobic lagoons are widely used to treat and store liquid manure from confined swine production facilities. Lagoon use and scale of production have a strong positive association: 41 percent of operations in the U.S. with at least 1,000 head used a lagoon, compared with only 22 percent of small scale operations (USDA, 2011). Environmental and health concerns with the lagoon technology include emissions of ammonia, odors, pathogens, and water quality deterioration (Vanotti and Szogi, 2008). Thus, there is a major interest in developing alternative swine manure treatment systems that can also address these environmental and health problems. In the U.S., North Carolina represents a state and region in which pork production activity has received national and international attention over the past two decades due, in part, to the rapid growth of this industry during the late 1980s to mid 1990s and subsequent attention directed to environmental, social, and political issues related to this growth, and, more recently, research and policy initiatives to develop ?Environmentally Superior Technologies? (EST) to address these issues (Williams, 2006). Widespread objection to the use of anaerobic lagoons for swine manure treatment in North Carolina prompted a government-industry-university framework to develop alternative technologies that would eliminate anaerobic lagoons as a method of treatment. This framework established an agreement between government and swine industry to develop and demonstrate environmentally superior waste management technologies.

An EST is defined as any technology or combination of technologies that is permittable by the appropriate governmental agencies, is determined to be technically, operationally, and economically feasible, and meets the following five environmental performance standards (Williams, 2006):

(1) Eliminate the discharge of animal waste to surface waters and groundwater through direct discharge, seepage, or runoff;

(2) Substantially eliminate atmospheric emissions of ammonia;

(3) Substantially eliminate the emission of odor that is detectable beyond the boundaries of farm;

(4) Substantially eliminate the release of disease-transmitting vectors and airborne pathogens; and

(5) Substantially eliminate nutrient and heavy metal contamination of soil and groundwater.

Five of the 18 technologies tested under this agreement were shown to be capable of meeting the environmental performance criteria necessary for the technologies to be considered EST (Williams, 2006, 2007). One of the EST selected technologies treated the liquid manure on-farm using a system that combined three of the technologies shown in Figure 3: enhanced separation with flocculants, nitrification/ denitrification, and soluble phosphorus removal modules. The solids separation provided dewatered manure solids amenable for transport off farm and generation of value-added products with additional treatment. The other four technologies awarded EST certification further processed separated manure solids using composting, high-solids anaerobic digestion, or gasification processes that produced a variety of products such as class A composts, organic fertilizers, and energy.

Consequently, in July 2007 the State of North Carolina enacted Senate Bill 1465 that made permanent the five environmental performance standards of an EST as a requirement for the construction of new swine farms or expansion of existing swine farms in North Carolina (General Assembly of North Carolina, 2007). It also established a Lagoon Conversion Program that provides financial incentives to assist producers in the conversion of anaerobic swine lagoons to technologies that meet EST environmental standards.

EST DEMONSTRATION PROJECT AND ENVIRONMENTAL BENEFITS

Scientists at the ARS Center at Florence and industry cooperators designed and demonstrated a second generation treatment system for swine waste that achieved environmental standard performance of an Environmentally Superior Technology, yet it was much more economical than earlier versions. The system combined solid-liquid separation using polymer flocculation, biological ammonia treatment using nitrification/denitrification, and phosphorus removal using a module that recovered the phosphates and killed the pathogens. The system produced a deodorized and disinfected liquid effluent (Vanotti et al., 2009b). It also recycled clean water to flush the barns. The treated water was stored in the former lagoon and used for crop irrigation. The solids were removed from the farm, composted, and used for the manufacture of valueadded products (Vanotti., 2005). It was the first complete system certified by the State of North Carolina as an EST due to its efficacy in reducing problems of ammonia emissions, excess nitrogen, phosphorus, pathogens, odors, and heavy metals.

Figure 4: Second-generation environmentally superior waste treatment system in North Carolina cleaning the waste from seven barns (5,200 finishing pigs).

The second generation system was installed full-scale on a 5,200-head finishing swine operation and demonstrated during three production cycles (15-months) under steady-state conditions (Figure 4).

Water Quality Improvements

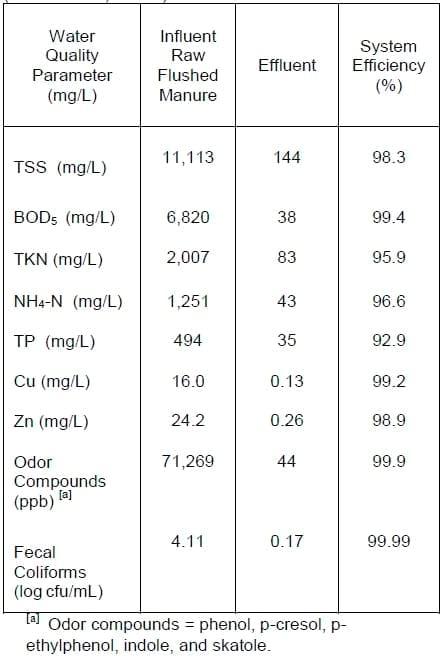

Table 1 shows the values of various water quality indicators as the liquid passed through each treatment module in the EST system and the overall efficiency of concentration reduction for these parameters. In cleaning up manure wastewater, the system removed 99.99 percent of pathogens, 99 percent of odor-causing components, 95 percent of total phosphorus, 97 percent of ammonia, and more than 99 percent of heavy metals copper and zinc. The cleaned water was stored in the old waste lagoon. As a result, it was cleaned quickly (Figure 5).

Table 1. Wastewater treatment plant performance and system efficiency at Tyndall farm, North Carolina (Vanotti et al., 2009b).

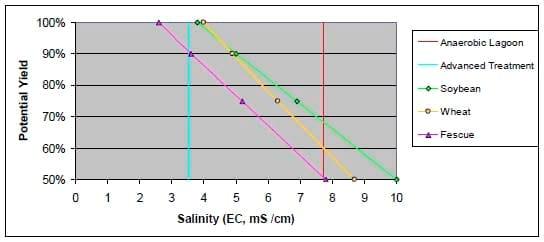

The treated liquid can be used effectively for irrigation of crops. Data in Figure 6 show that the lower salinity of the treated liquid enables its use for crop irrigation with optimized yields.

Air Quality Improvements

The quality of the air was improved significantly. Odor compounds (phenol, p-cresol, p-ethylphenol, indole, and skatole) were reduced 99.9% (Loughrin et al, 2008). Compared to the previous lagoon technology, the ammonia emissions were reduced 94.7% during the warm season and 99.0% during the cool season using the new system (Aneya et al., 2008).

Figure 5: Clean-up of the environment with the new technology. Top picture shows the previous waste lagoon at the time the new plant was started. Bottom picture shows the same lagoon 10 months later.

Figure 6: Potential yields of soybean, wheat and fescue using irrigation with treated effluent versus anaerobic lagoon effluent (EC data from Vanotti and Szogi, 2008; yields from FAO).

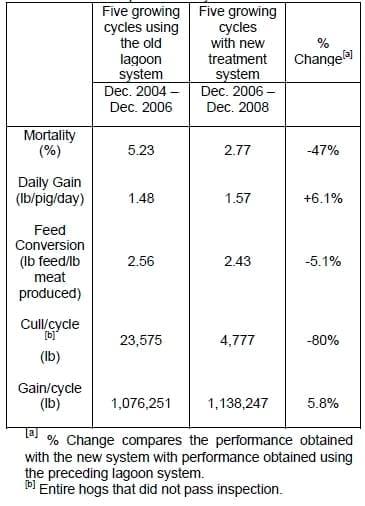

Animal Productivity and Health Improvements

Substantial animal production advantages can be realized by improvements in manure management. Barker (1996) documented with many examples the direct linkage between improved manure management and animal productivity and health. Indicators of better productivity and health were healthier pigs, reduced mortality, increased daily gain, improved feed conversion, and substantial economic benefits to the producer. The reuse of cleaner, sanitized water (ammonia free) to refill barn pits reduced ammonia concentration in the air and improved the growing environment. Ambient ammonia levels in the barns dropped an average of 75 percent, from 11.3 to 2.8 ppm. As a result, animal health and productivity were enhanced (Table 2). Daily weight gain increased 6.1 percent, and feed conversion improved 5.1 percent. Animal mortality decreased 47 percent, and cull weight was reduced 80 percent (Table 2). The farmer sold an average of 5,265 pigs per growing cycle, which resulted in a 1,138,247- pound net gain per cycle. Using the EST system instead of the lagoon system, the farmer sold 61,996 pounds more hogs—a 5.8 percent increase—per growing cycle. Results obtained in this demonstration project are consistent with the observations of Barker (1996) on the substantial animal production advantages that can be realized by improvements in manure management in swine production buildings.

Table 2. Improvement of animal productivity and health indicators obtained with the new waste treatment system compared with the previous lagoon system at the same farm. Data are means of production records obtained in seven barns during five production cycles before conversion and five production cycles after conversion.

Value-added Products

Composting of the separated manure solids was done in a centralized facility (Vanotti et al., 2006). In this facility, the solids were combined with cotton gin waste to optimize the composting process. The produced composts conserved 95-100% of the nitrogen and other nutrients and met EPA Class A biosolids quality standards due to low pathogen levels. The high-quality composts are used for the commercial manufacture of soil amendments, organic fertilizers, and potting soil.

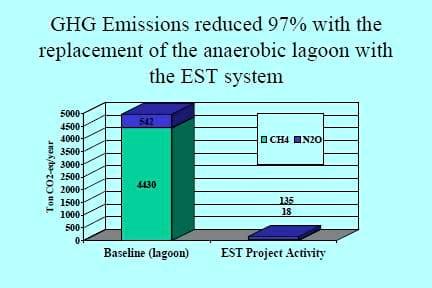

Mitigation of GHG Emissions

In addition to the strict environmental standards with which EST's need to comply (i.e., the elimination of pathogens, ammonia emissions, odor, heavy metals, phosphorus, discharge to surface and groundwater, etc.), they can also be very effective reducing GHG emissions (both methane and nitrous oxide), even more than anaerobic digesters per-se. Using protocols adopted though the United Nations Framework Convention on Climate Change (UNFCCC), we estimated a 96.9% reduction in GHG emissions by replacement of the traditional lagoon-spray field technology with this cleaner EST technology that uses solids separation, composting, and biological N treatment (Figure 7).

The new system was discussed in a chapter of ?Manufacturing Climate Solutions: Carbon-Reducing Technologies and U.S. Jobs, published in 2008 by Duke University (Gereffi et al., 2008). The report was commissioned by the AFL-CIO and the Environmental Defense Fund and featured technologies that could help reduce greenhouse gas emissions and create green jobs in the United States.

Figure 7: Reduction of greenhouse gas emissions (methane and nitrous oxide) after replacement of lagoon system with environmentally superior waste treatment system in North Carolina.

MORE ECONOMICAL AMMONIA REMOVAL WITH ANAMMOX

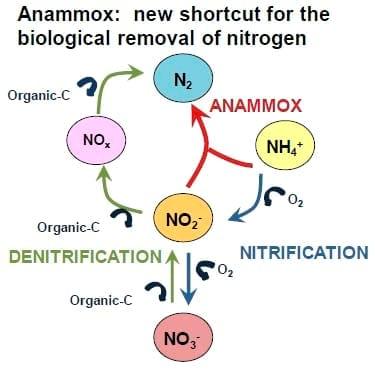

Anammox bacteria have been discovered recently; it provides an environment-friendly and lower-cost alternative to nitrification/denitrification for biological removal of the ammonia (Figure 3). Anammox bacteria gain their energy for growth from the oxidation of ammonium with nitrite to make dinitrogen gas without the need of carbon (Figure 6). It is especially suited for the ammonia treatment in anaerobic digester effluents. Livestock producers that would like to remove nitrogen from the effluent of anaerobic digesters – for example to comply with surplus nitrogen regulations or to take advantage of environmental nutrient credit programs – are often limited by the low amount of endogenous carbon available for traditional denitrification, since the carbon is consumed in the biogas production. In the future, we will be able to use deammonification treatment with new anammox bacteria to solve this problem (Figure 8).

We evaluated deammonification treatment using a single, fluidized, aerobic tank by mixing a high performance nitrifying sludge and anammox bacteria (Vanotti et al., 2012). Compared to traditional nitrification/denitrification, the partial nitritation/anammox process in a single tank showed several advantages: 1) reduced 56% of the oxygen requirements to remove the ammonia; 2) it eliminated carbon needs for denitrification; and 3) it removed nitrogen at higher rates, further reducing equipment costs. Therefore, deammonification can be a key technology for development of more economical and energyefficient biological ammonia removal systems in the near future.

Figure 8: Deammonification involves two steps: ammonia oxidizing bacteria that convert about half of the wastewater ammonia (NH4+) into nitrite (NO2-) (partial nitritation), and new anammox bacteria that utilize the remaining ammonia (NH4 +) and nitrite (NO2 -) to produce harmless N2.

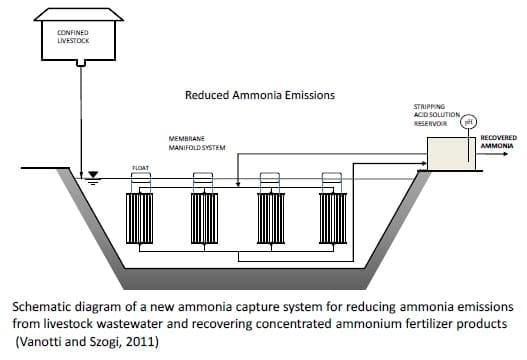

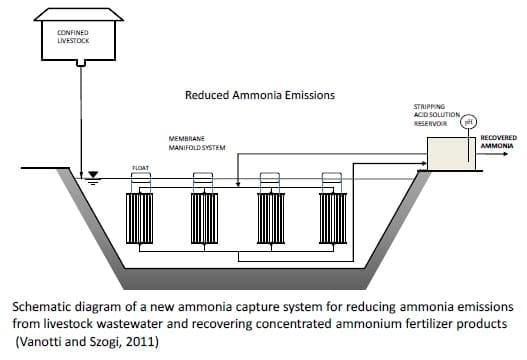

AMMONIA RECOVERY

The recovery of nitrogen (N) from wastes will be important in agriculture because of the high cost of commercial N fertilizers and the environmental damage of the release of reactive nitrogen. We are developing new systems and methods that use gas-permeable membranes to recover significant amounts of ammonia when operated in liquid manure such as lagoon and solids-separated swine wastewater (Vanotti and Szogi, 2011). The new process includes the passage of gaseous ammonia through a microporous hydrophobic membrane and subsequent capture and concentration in a stripping solution on the other side of the membrane. Membrane manifolds are submerged in the liquid, and the gaseous ammonia is removed from the liquid before it escapes into the air (Figure 9).

Figure 9: Depiction of a gas-membrane ammonia recovery system to harvest the nitrogen from manure structures and reduce ammonia emissions.

The new concept was tested using concentrated swine manure effluents containing 140 to 1,400 mg/L ammonium nitrogen (Vanotti and Szogi, 2011). The use of gas-permeable membranes to remove ammonia from liquid manure was effective, and the rate of N recovery by the gas-permeable membrane system was higher with higher ammonia concentration in the manure. While ammonia gas passed readily through the membrane pores, the soluble COD compounds did not pass, resulting in a clean and high concentration ammonia solution. By using the same stripping solution in 10 consecutive batches treating separated swine manure, the recovered N was concentrated in a clear solution containing 53,000 mg/L ammonium nitrogen. The final products are (1) reduced environmental emissions from livestock facilities and (2) concentrated liquid nitrogen that can be re-used in agriculture as a valued fertilizer or transported greater distances for alternative utilization strategies. The results obtained show that the use of gas-permeable membrane technology could be an effective approach to recover ammonia from livestock wastewater.

CONCLUSIONS

Environmental and policy issues associated with the production of pork are specific for each region; however, regardless of location, these issues generally include land application of manure and potential discharge of manure nutrients (nitrogen and phosphorus) and pathogenic bacteria to surface and groundwater; and aerial emissions of ammonia, methane, pathogens and odor.

One of the main outputs of the OECD Workshop "Livestock waste treatment systems of the future: A challenge to environmental quality, food safety, and sustainability" (Vanotti et al., 2009a) was the importance of collaborative links, cooperation and integration of research activities and practices, and on setting clear goals to solve problems. Animal production and management of its wastes are strategic for the economy, food security, public health, and environmental protection of each country. Many holistic treatment solutions to manure management are currently available; however, in each country it is important to identify the regional and/or national animal waste problems, set goals, and develop customized solutions to achieve these goals. In addition to typical goals of improved air, soil and water quality, and animal and public health, future treatment systems should also address nutrient recovery, energy, and water conservation.

REFERENCES

Aneja, V.P., Arya, S.P., Rumsey, I.C., Kim, D.S., Bajwa, K., and Williams, C.M. 2008. Characterizing Ammonia Emissions from Swine Farms in Eastern North Carolina: Reduction of emissions from waterholding structures at two candidate superior technologies for waste treatment. Atmospheric Environment, 42:3291-3300.

Barker, J.C. 1996. Effects of manure management practices on air quality and animal performance in swine production buildings. North Carolina Cooperative Extension Service. Pub. No. EBAE 180-93. https://www.bae.ncsu.edu/programs/extension/publicat/ wqwm/ebae180_93.html

General Assembly of North Carolina, Session 2007, Senate Bill 1465. Available from: http://www.ncleg.net/Sessions/2007/Bills/Senate/HTML/ S1465v7.html

Gereffi, G., Dubay, K., Lowe, M. 2008. Manufacturing Climate Solutions: Carbon- Reducing Technologies and U.S. Jobs. Center on Globalization, Governance & Competitiveness, Duke University. http://www.whitehouse.gov/assets/documents/Krupp_Ha ndout.pdf

EPA. 2012. Anaerobic Digestion of Manure. U.S. Environmental Protection Agency, AG-Star program. http://www.epa.gov/agstar/anaerobic/ad101/index.html

Loughrin, J.H., Vanotti, M.B., Szogi, A.A. and Lovanh, N. Evaluation of second-generation multistage wastewater treatment system for the removal of malodors from liquid swine waste. J. Environ. Qual. 38:1739-1748. 2009. http://naldc.nal.usda.gov/download/31763/PDF

USDA-NRCS. 2008. Conservation information guide—North Carolina A Guide To Understanding USDA NRCS Comprehensive Nutrient Management Plans. ftp://ftpfc. sc.egov.usda.gov/NC/NCweb/Technical/technicalreferences/ CNMPinformationguide08release_version.pdf

USDA. 2001. Confined Animal Production and Manure Nutrients. Agriculture Information Bulletin No. (AIB-771) http://www.ers.usda.gov/publications/aib-agriculturalinformation- bulletin/aib771.aspx

USDA-NASS. 2007. Census of Agriculture: Hog and pig farming. http://www.agcensus.usda.gov/Publications/2007/Online _Highlights/Fact_Sheets/Production/hogsandpigs.pdf

USDA-ERS. 2011. Trends and developments in hog manure management:1998-2009. USDA-ERS EIB-81. http://www.ers.usda.gov/media/106384/eib81_1_.pdf

Vanotti, M. B. 2005. Evaluation of Environmentally Superior Technology: Centralized composting unit. Phase II: Final Report for Technology Determination per Agreements between NC Attorney General & Smithfield Foods, Premium Standard Farms, and Frontline Farmers. http://www.cals.ncsu.edu/waste_mgt/smithfield_projects/ phase2report05/cd,web%20files/A1.pdf . 2005.

Vanotti, M.B., Millner, P.D., Szogi, A.A., Campbell, C.R. and Fetterman, L.M. 2006. Aerobic composting of swine manure solids mixed with cotton gin trash. ASABE Paper #064061. http://www.ars.usda.gov/SP2UserFiles/Place/66570000/ Manuscripts/2006/Man729.pdf

Vanotti, M.B. and Szogi, A.A. 2008. Water quality improvements of wastewater from confined animal feeding operations after advanced treatment. J. Environ. Qual. 37:S86-S96. http://www.ars.usda.gov/SP2UserFiles/Place/66570000/ Manuscripts/2008/Man784.pdf

Vanotti, M.B., Szogi, A.A., Bernal, M.P. and Martinez, J. 2009a. Livestock waste treatment systems of the future: A challenge to environmental quality, food safety, and sustainability. OECD Workshop. Biores. Technol. 100(22):5371-5373. http://www.ars.usda.gov/SP2UserFiles/Place/66570000/ Manuscripts/2009/Man813.pdf

Vanotti, M.B., Szogi, A.A., Millner, P.D. and Loughrin, J.H. 2009b. Development of a secondgeneration environmentally superior technology for treatment of swine manure in the USA. Biores. Technol. 100(22):5406-5416. http://www.ars.usda.gov/SP2UserFiles/Place/66570000/ Manuscripts/2009/Man812.pdf

Vanotti, M.B. and Szogi, A.A. 2011. US Patent Application SN 13/164,363, "Systems and Method for Reducing Ammonia Emissions from Liquid Effluents and for Recovering Ammonia", the Patent Assignee is the United States of America as represented by the Secretary of Agriculture.

Vanotti, M., Martinez, J., Fujii, T., Szogi, A., Hira, D. 2012. Ammonia Removal Using Nitritation and Anammox in a Single Reactor. ASABE Meeting Presentation # 121337837. Hilton Anatole Dallas, Texas July 29 – August 1, 2012

Williams, C.M., 2006. Development of Environmentally Superior Technologies: Phase 3 Report for Technology Determinations per Agreements Between the Attorney General of North Carolina and Smithfield Foods, Premium Standard Farms, and Frontline Farmers. March 8, 2006. http://www.cals.ncsu.edu/waste_mgt/smithfield_projects/ phase3report06/phase3report.htm

Williams, C.M., 2007. Phase 1 Environmentally Superior Technologies Contingent Determinations per Agreements between the Attorney General of North Carolina and Smithfield Foods, Premium Standard Farms, and Frontline Farmers: Second Generation Super Soils Technology. November 1, 2007. http://www.cals.ncsu.edu/waste_mgt/smithfield_projects/ supersoils2ndgeneration/ss2ndgenerationreport.html

This paper was presented at the XI National Congress of Swine Production (CNPP), VI Mercosur Congress of Swine Production, Salta, Argentina, August 14-17, 2012.

Watch the presentation in Spanish, clicking on the link below: