Stabilized Vitamin C Microencapsulated for Aquaculture

Published: November 21, 2019

By: Winston A. Samuels, Ph.D. Maxx Performance.

Introduction:

70% Ascorbic Acid (vitamin C) is a feed stable, microencapsulated (encapsulated) form of vitamin C for the aquaculture industry. It is also used in animal feeds. Maxx Performance’s proprietary barrier coating technology offers the best in highly stabilized vitamin C for optimum stability in the feeds for aquaculture and animals worldwide. 70% encapsulated, stabilized, vitamin C offers constant feed stability and proven enhanced bioavailability by using GRAS approved, nutrient based, coating materials. Fish can now realize the benefits of a widely known antioxidant to improve immunity, creating better tolerance of stress and diseases in a product that can either be topdressed or added straight to feeds.

Characteristics and performance

Composition:

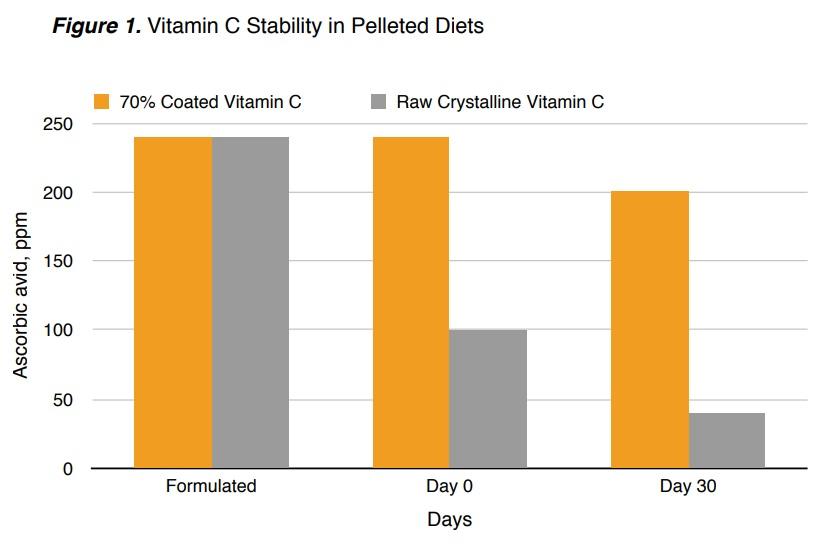

Stabilized 70% vitamin C is manufactured using 100% raw crystalline ascorbic acid which, comprises 70% of the total weight of the product. The other 30% is GRAS approved coating material, consisting of fully hydrogenated vegetable oil. The process used creates a white to off white material of free-flowing particulate granules, with a particle size of 100% through 10 mesh (1885 µ) screen (USSS). Feed processing and storage Stabilized 70% ascorbic acid is a coated source of vitamin C which allows vitamin C to survive through cold and steam pelleting conditions. In cold pelleting, there is almost 100% retention of the vitamin C through processing and delivery. During steam pelleting there is a 94% stability; (Figure 1) through the pelleting process and the ability to have up to 180 days of shelf life depending upon the steam pelleting application. Extrusion conditions are much more severe than either cold or steam pelleting, and the current 70% vitamin C product form is not a strong fit for extrusion. Under extrusion there is less than 50% retention. Products that involved other process may be more suitable for extrusion than 70% microencapsulated ascorbic acid.

Bioavailability

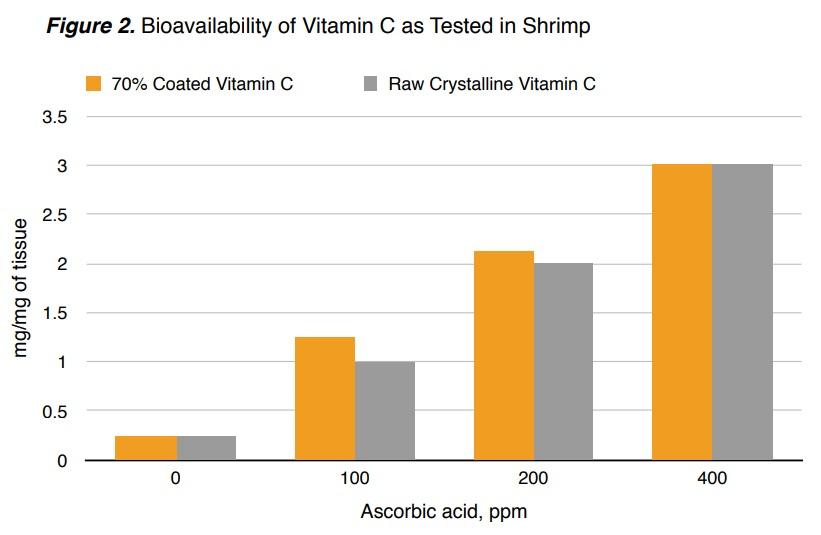

Dr. Douglas Conklin at the University of California, Davis Animal Science department, evaluated the bioavailability of 70% ascorbic acid in the diets of Penaeid shrimp. Penaeid shrimp were fed increasing amounts of either raw ascorbic acid or 70% vitamin C. None of the treatment groups was exposed to feed processing in order to prevent potential losses of the raw ascorbic acid due to feed processing. The raw dosage was adjusted for leach rate in water upon administration to obtain a true assessment of the performance of the coated microencapsulated vitamin C. By comparing tissue enrichment of ascorbic acid (Figure 2), it was determined that shrimp fed the 70% vitamin C had the same bioavailability as the raw ascorbic acid.

Use in Aquaculture

Fish cannot synthesize vitamin C so it has to be added in their feed. Some vitamin C is provided by dietary ingredients, however, under the majority of situations supplemental ascorbic acid is generally required. In supplementing ascorbic acid to fish, adjustments must be made to accommodate the losses that occur during feed processing and storage, and also losses that occur due to leaching of the ascorbic acid into the water. Chemically and physically stabilized forms of vitamin C exist to deal with these losses of vitamin C and are used widely in the aquaculture industry.

The preferred form of ascorbic acid to use depends upon feed processing conditions and the specie fed. For cold pelleting diets, Maxx Performance 70% ascorbic acid, which is physically stabilized using high quality proprietary microencapsulation coating technology is preferred over ascorbic acid with phosphate groups where enzymes present in the feed matrix can cleave the phosphate groups off chemically stabilized ascorbic acid, lowering its overall stability. For steam pelleted diets, either chemically or physically stabilized vitamin C can be effective. For this application both are comparable on a cost in use basis. However, for species with short gastrointestinal tracts, such as shrimp, 70% Ascorbic Acid, which is physically stabilized, has been shown to be completely bioavailable, whereas, chemically stabilized ascorbic acid may not be completely available due to incomplete cleavage of the phosphate esters off the ascorbic acid molecule. On the other hand, in extruded feeds, chemically stabilized ascorbic acid is likely the preferred form, as it is far more resistant to the processing conditions of extrusion than 70% ascorbic acid. Target dosages differ by specie and life cycle stage, but typically are 100 ppm.

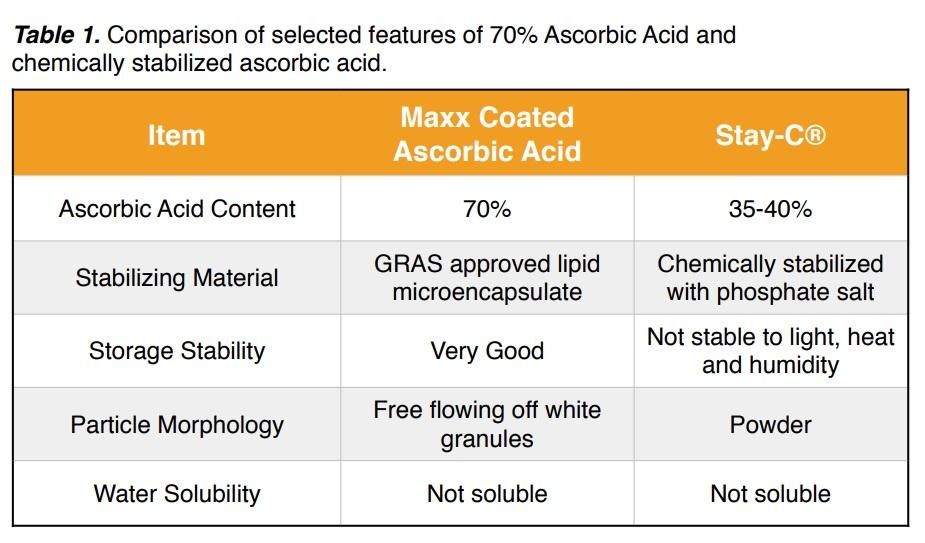

The difference between 70% physically stabilized coated vitamin C and competitive chemical products/technologies

70% ascorbic acid is typically compared against other forms of ascorbic acid. The alternative technology to microencapsulation is chemical stabilization of ascorbic acid phosphorylated sodium and calcium salts of ascorbic acid. These products are water insoluble, are resistant to feed processing conditions, and are about 35 to 40% ascorbic acid by weight.

The ascorbic acid in chemically stabilized ascorbic acid is bioavailable, as long as the animal cleaves off the phosphate salts. Cleavage of the phosphate salts typically occurs readily in most species, but may not happen completely in species with short gastro-intestinal tract such as shrimp. Since these products are chemically stabilized, the product is still exposed to environmental conditions during storage and use, and may lose stability due to heat, light, and humidity during storage, especially if the packaging material is not closed quickly and tightly following use. Subsequently, in feeds in which there are enzymatic activity present, such as cold pelleted feeds for aquaculture, environmental phosphorylase enzymes can destabilize the products rapidly, lowering the retention and supply to the fish when feeding occurs.

70% stabilized coated microencapsulated ascorbic acid is the recommended product for use in cold pelleted diets, because the enzymes in the feed matrix of cold pelleted feeds will cleave the phosphate esters of chemical stabilized ascorbic acid which significantly lowers vitamin C stability. Chemically stabilized vitamin C will have comparable stability in steam pelleting applications. For extruded feed applications, chemical stabilized ascorbic acid is preferable to 70% physically stabilized ascorbic acid.

Cost / Benefit

One of the best ways to evaluate the cost/benefit of 70% coated stabilized ascorbic acid is the predicable benefit of its use to illicit a biological effect such as improving immunity and concomitant disease resistance. It is known that raw vitamin C is unstable so, in most feed applications, it is typically not added because of its relative instability during processing and storage, and delivery in the feed to the diets of aquaculture based animals. The industry has long recognized the disadvantages of using raw vitamin C in processed feeds, and in general, has been using some form of stabilized vitamin C when vitamin C is used in the diets of aquaculture and other animals.

Stabilized ascorbic acid can take the form of ethyl cellulose coated ascorbic acid, chemically stabilized vitamin C such as Stay-C® and others or a microencapsulated coated stabilized vitamin C such as 70% vitamin C. Each product form has advantages and disadvantages. Overall, the differences between the product forms will come down to how much is retained compared to their unit cost per kilogram, or their cost in use adjusted for processing and storage losses.

Maxx Performance’s microencapsulation system allows for protection of ingredients from their surrounding environment; shielding individual particles of ingredients from degradation and pre-reaction and delivering them for optimum performance at nominal cost with no process change. Our technology is an advanced tool that enables the use of ingredients that traditionally present challenging technical issues for specific applications. Maxx Performance provides off-the-shelf microencapsulated ingredients and custom toll manufacturing of individual or multiple ingredients in a single microcapsule.

Related topics:

Authors:

Maxx Performance

Recommend

Comment

Share

Recommend

Reply

13 de febrero de 2022

Hello,

Can we use it in topical vitamin c preparations?

Mark

info@dermosoie.com

Recommend

Reply

Would you like to discuss another topic? Create a new post to engage with experts in the community.

.jpg&w=3840&q=75)