Feed Additive Mythbusters

Feed Additive Mythbusters: How Should we Feed Synthetic Amino Acids?

Published: August 21, 2012

By: Michael T. Kidd (Center of Excellence for Poultry Science & Department of Poultry Science, University of Arkansas,Fayetteville, AR, USA) and P. B. Tillman (Poultry Technical Nutrition Services, LLC, Buford, GA, USA)

Myths that have erroneously limited feed-grade amino acid inclusion in poultry diets have been dispelled in these proceedings by presentation of a historical perspective. In addition, recent research has been presented which has allowed for aggressive feed-grade amino acid inclusion that maintains good bird performance in diets with reduced costs and environmental impact. Namely, in the past 10 to 15 years numerous research reports have delineated threonine, valine, and isoleucine needs in various genetic strains and time periods of bird growth. Indeed, optimization of feed-grade amino acids requires a continual evaluation of lysine needs for a reference as bird genotypes continually change in terms of food intake and tissue accretion patterns. Moreover, as dietary ingredients, growth promotants, and enzymes programs evolve, the dietary threonine need should also be evaluated for optimal industrial protein synthesis and health.

I. INTRODUCTION

These proceedings accompany a presentation addressing the question: How should we use feed-grade amino acids in commercial poultry diets? References dating back to the 1950s are used herein to highlight key factors that have impacted the use of feed-grade amino acids. High emphasis is placed on amino acid research in broilers conducted during the past ten years as much of this work is focused on predicting the dietary needs of the branched chain amino acids. Hence, accurate ratios of the branched chain amino acids to lysine, coupled with an understanding of minimum nutrient levels of the less limiting amino acids for a nonessential nitrogen pool, are critical for future advances in the use of feed-grade amino acids.

I. INTRODUCTION

These proceedings accompany a presentation addressing the question: How should we use feed-grade amino acids in commercial poultry diets? References dating back to the 1950s are used herein to highlight key factors that have impacted the use of feed-grade amino acids. High emphasis is placed on amino acid research in broilers conducted during the past ten years as much of this work is focused on predicting the dietary needs of the branched chain amino acids. Hence, accurate ratios of the branched chain amino acids to lysine, coupled with an understanding of minimum nutrient levels of the less limiting amino acids for a nonessential nitrogen pool, are critical for future advances in the use of feed-grade amino acids.

II. THE EARLY YEARS

The theme of the feed additives section of this symposium, of which these proceedings fall under, is “mythbusters.” This term is well-suited for feed-grade amino acids in poultry. A few common past myths in amino acid nutrition of poultry are provided. In the 1950s many nutritionists believed protein needs could never be replaced by feed-grade amino acids. In the 1980s, many nutritionists said broiler diets should not contain more than one pound of Llysine per ton. In the 1990s, many nutritionists said L-threonine would never enter a broiler diet formulation. Clearly, these myths have been dispelled.

Amino acid feed-additive use began in the mid-1950s with the introduction of both feed formulation and dry methionine hydroxy analogue calcium. The first diet formulated using linear programming was a dairy ration (Waugh, 1951). Thereafter, a group at the Pennsylvania State University Experiment Station led an effort in formulating poultry diets (Hutton et al., 1958) by publishing a series of seven articles in Feedstuffs magazine. The first issue on acceptance of feed-grade amino acids in poultry diets arose with linear programming, as poultry industry nutritionists and many university scientists could not afford computers. Later that year, Hutton (1958) published an article on least-cost poultry diets that included corn, soybean meal, and a methionine source. Because diet cost was $70.95 USD/2000 pounds and the methionine source represented $5.73 USD ($2.18 USD/pound) of total diet cost, few accepted any efficacy of a feed-grade methionine source. The second issue arose with the dietary inclusion of feed-grade methionine, because reduced protein and amino acid balance were as foreign as computer formulation. As a result, the Monsanto Chemical Company invested in a computer system and formulated feed as a service to its customers in the US.

The theme of the feed additives section of this symposium, of which these proceedings fall under, is “mythbusters.” This term is well-suited for feed-grade amino acids in poultry. A few common past myths in amino acid nutrition of poultry are provided. In the 1950s many nutritionists believed protein needs could never be replaced by feed-grade amino acids. In the 1980s, many nutritionists said broiler diets should not contain more than one pound of Llysine per ton. In the 1990s, many nutritionists said L-threonine would never enter a broiler diet formulation. Clearly, these myths have been dispelled.

Amino acid feed-additive use began in the mid-1950s with the introduction of both feed formulation and dry methionine hydroxy analogue calcium. The first diet formulated using linear programming was a dairy ration (Waugh, 1951). Thereafter, a group at the Pennsylvania State University Experiment Station led an effort in formulating poultry diets (Hutton et al., 1958) by publishing a series of seven articles in Feedstuffs magazine. The first issue on acceptance of feed-grade amino acids in poultry diets arose with linear programming, as poultry industry nutritionists and many university scientists could not afford computers. Later that year, Hutton (1958) published an article on least-cost poultry diets that included corn, soybean meal, and a methionine source. Because diet cost was $70.95 USD/2000 pounds and the methionine source represented $5.73 USD ($2.18 USD/pound) of total diet cost, few accepted any efficacy of a feed-grade methionine source. The second issue arose with the dietary inclusion of feed-grade methionine, because reduced protein and amino acid balance were as foreign as computer formulation. As a result, the Monsanto Chemical Company invested in a computer system and formulated feed as a service to its customers in the US.

Bray and Garlich (1960) were the first to document large responses to amino acids in low-protein diets. They supplemented DL-methionine, L-lysine HCl, DL-tryptophan, DLisoleucine, and DL-valine to a 9% crude protein diet (corn- and soybean-meal-based) and documented improved egg production and nitrogen retention similar to a diet higher in crude protein. They attributed their amino acid responses, and the lack of responses in previous research (Thornton et al., 1957), to the extent to which crude protein was reduced.

Subsequent research in the 1960s was conducted to determine the efficacy of feedgrade methionine and lysine sources. Harms et al. (1962) conducted studies in laying hens fed corn and soybean meal diets and found an improvement in laying performance from methionine hydroxy analogue calcium in the presence of reduced dietary protein. Additional research from the same laboratory (Harms and Waldroup, 1963) evaluated both methionine and lysine in Hy-Line pullets fed diets based on corn and soybean meal. They demonstrated the nutrient limitation of both methionine and lysine by supplementing lower-protein diets with methionine hydroxyl analogue calcium and L-lysine HCl. The former research and other reports of the like allowed for more accurate formulation with feed-grade methionine and lysine throughout the 1970s and 1980s. But it was not until the 1990s that commercialization of L-threonine allowed for a more full optimization of lysine in diets reduced in crude protein.

III. 1990s: THE THREONINE YEARS

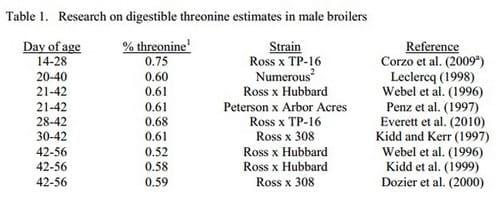

A myth that was in place by some nutritionists in the 1990s was a dietary restriction on the amount of feed-grade L-lysine that could enter dietary formulation. This restriction, sometimes 400 to 500 grams/ton, allowed nutritionists to solve for total sulfur amino acids and lysine while other amino acids were in excess. Research throughout the 1990s provided threonine estimates (Kidd, 2000) which aided nutritionists in dispelling the feed-grade Llysine restriction and closer meeting the birds’ needs for essential amino acids. The 1990s was an important decade for threonine because it represents the third limiting amino acid in most commercial poultry feeds and little prior research existed in growing and finishing broilers (Table 1). However, commercial production of L-threonine in the 1980s created interest and some laboratories delineated requirement estimates. Much of the threonine research conducted focused on needs of chicks (Thomas et al., 1979, 1986, 1987; Uzu, 1986; Smith and Waldroup, 1988; Robbins, 1987). The limiting factors for commercial L-threonine use in the early 1990s were price and lack of requirement estimates in the growing and finishing periods. The latter limitation required research, since the threonine need for bird maintenance is substantial relative to lysine. In a past Australian Poultry Science Symposium (Kidd, 1999) it was pointed out that the inclusion of wheat or sorghum cereals rather than corn will place more constrains on formulation to meet dietary threonine needs in broiler chickens.

III. 1990s: THE THREONINE YEARS

A myth that was in place by some nutritionists in the 1990s was a dietary restriction on the amount of feed-grade L-lysine that could enter dietary formulation. This restriction, sometimes 400 to 500 grams/ton, allowed nutritionists to solve for total sulfur amino acids and lysine while other amino acids were in excess. Research throughout the 1990s provided threonine estimates (Kidd, 2000) which aided nutritionists in dispelling the feed-grade Llysine restriction and closer meeting the birds’ needs for essential amino acids. The 1990s was an important decade for threonine because it represents the third limiting amino acid in most commercial poultry feeds and little prior research existed in growing and finishing broilers (Table 1). However, commercial production of L-threonine in the 1980s created interest and some laboratories delineated requirement estimates. Much of the threonine research conducted focused on needs of chicks (Thomas et al., 1979, 1986, 1987; Uzu, 1986; Smith and Waldroup, 1988; Robbins, 1987). The limiting factors for commercial L-threonine use in the early 1990s were price and lack of requirement estimates in the growing and finishing periods. The latter limitation required research, since the threonine need for bird maintenance is substantial relative to lysine. In a past Australian Poultry Science Symposium (Kidd, 1999) it was pointed out that the inclusion of wheat or sorghum cereals rather than corn will place more constrains on formulation to meet dietary threonine needs in broiler chickens.

Four laboratories in the 1990s published threonine needs between 20 and 42 days of age and generated estimates of digestible threonine between 0.60 and 0.61% of diet (Webel et al., 1996; Leclercq, 1998; Penz et al., 1997; Kidd and Kerr, 1997). In older broilers (42 to 56 days of age), threonine estimates vary. Webel et al. (1996) determined that the digestible threonine need for 42- to 56-day-old broilers was 0.52%, whereas Dozier et al. (2000) and Kidd et al. (1999) estimated digestible needs of 0.59 and 0.58%, respectively. The later estimates may be higher than that of Webel et al. (1996) because trials were carried out in floor pen environments with built-up litter.

Wu (1998) published an article delineating amino acid catabolism of intestinal mucosa. It was hypothesized that 30 to 50% of arginine, proline, isoleucine, valine, leucine, methionine, lysine, phenylalanine, threonine, glycine, and serine are utilized for enzyme and tissue needs and are not available to extraintestinal tissues. Regarding threonine, Bertolo et al. (1998) indicated that piglets fed intragastrically have a threonine requirement 45% less than piglets fed orally, indicating the importance of threonine in intestinal functionality. Last year at the Australian Poultry Science Symposium meeting, Moran (2011) discussed the importance of meeting the mucin amino acid need in diets lowered in crude protein. Hence, reduced performance in broilers fed low crude protein diets may be more of a need for mucin, rather than a direct function of amino acid digestibility or availability.

Wu (1998) published an article delineating amino acid catabolism of intestinal mucosa. It was hypothesized that 30 to 50% of arginine, proline, isoleucine, valine, leucine, methionine, lysine, phenylalanine, threonine, glycine, and serine are utilized for enzyme and tissue needs and are not available to extraintestinal tissues. Regarding threonine, Bertolo et al. (1998) indicated that piglets fed intragastrically have a threonine requirement 45% less than piglets fed orally, indicating the importance of threonine in intestinal functionality. Last year at the Australian Poultry Science Symposium meeting, Moran (2011) discussed the importance of meeting the mucin amino acid need in diets lowered in crude protein. Hence, reduced performance in broilers fed low crude protein diets may be more of a need for mucin, rather than a direct function of amino acid digestibility or availability.

Research by Kidd et al. (2003) and Corzo et al. (2007b) evaluated dose titrations of dietary threonine in birds from 42 to 56 days of age placed in pens with new or old litter. Although both studies predicted threonine needs of birds raised on old litter of 0.61% and 0.65% digestible respectively, it was shown that birds raised in the pens with old litter had threonine needs at least 4% higher than those in pens with clean litter. Therefore, it must be pointed out that consideration of environment and litter type should be taken into consideration for threonine research trials for resultant industry applicability.

How much does the dietary threonine requirement vary in birds differing in intestinal environments? Proteins in the intestinal mucus layer, an important non-immune intestinal barrier, have been shown to contain 30% threonine (Neutra and Forstner, 1987). Azzam et al. (2011) provided Babcock Brown laying hen’s threonine in excess of published standards (NRC, 1994) and noted increases in jejuna and ileal mucin2 in RNA expression. Trends were also observed for increases in jejuna and ileal IgA with threonine levels in excess of needs for egg production. The extent to which threonine needs should be increased in birds with intestinal compromises (all vegetable-based diets and/or intestinal bacteremia) should be researched further for accurate threonine predictions that can be used in industry feed formulation. Moreover, threonine estimates that accurately reflect needs of birds in practice will allow for optimization of the 4th limiting amino acid. The most likely candidates for the 4th limiting amino acid in broiler diets are valine, isoleucine, tryptophan or arginine, but will vary relative to the ingredients used in formulation (Kidd and Hackenhar, 2005).

1Average of body weight gain and feed conversion estimates.

2Mathematical model predictions from selected published research reports

2Mathematical model predictions from selected published research reports

IV. THE 2000S: VALINE AND ISOLEUCINE YEARS

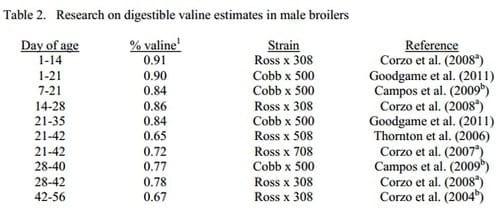

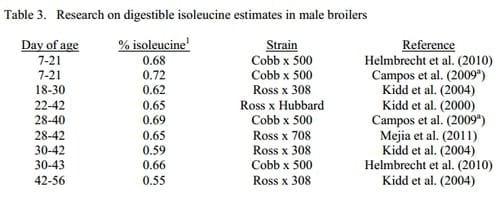

In an effort to maintain adequate levels of a pool of amino acid nitrogen for non-essential de novo synthesis, the past few years have given rise to numerous reports on the dietary needs for the essential branched chain amino acids: valine, isoleucine and leucine. As leucine is considered to be less limiting in practical diets, the bulk of the emphasis has been placed on valine and isoleucine. A review paper of recently published reports on valine and isoleucine requirement estimates for broilers has been made (Tillman, 2011) and a summary from that paper is presented in Tables 2 & 3, respectively. Research with feed grade L-valine has increased as it is completely available to the bird (Rodehutscord and Fatufe, 2005) and became commercially available in 2008. Corzo et al. (2011) showed that L-valine could be successfully used at an inclusion level above 0.05%, in practical broiler diets, which also contained DL-methionine, L-lysine HCl and L-threonine. Several published papers (Corzo et al., 2007a, 2009b, 2010), have noted in all vegetable based broiler diets, with corn and wheat as the primary grain, valine is the fourth limiting amino acid.

In an effort to maintain adequate levels of a pool of amino acid nitrogen for non-essential de novo synthesis, the past few years have given rise to numerous reports on the dietary needs for the essential branched chain amino acids: valine, isoleucine and leucine. As leucine is considered to be less limiting in practical diets, the bulk of the emphasis has been placed on valine and isoleucine. A review paper of recently published reports on valine and isoleucine requirement estimates for broilers has been made (Tillman, 2011) and a summary from that paper is presented in Tables 2 & 3, respectively. Research with feed grade L-valine has increased as it is completely available to the bird (Rodehutscord and Fatufe, 2005) and became commercially available in 2008. Corzo et al. (2011) showed that L-valine could be successfully used at an inclusion level above 0.05%, in practical broiler diets, which also contained DL-methionine, L-lysine HCl and L-threonine. Several published papers (Corzo et al., 2007a, 2009b, 2010), have noted in all vegetable based broiler diets, with corn and wheat as the primary grain, valine is the fourth limiting amino acid.

In broiler diets, which contain animal by-products, research has suggested the existence of a co-limitation between valine and isoleucine (Corzo et al., 2009b, 2010; Dozier et al., 2011). From these papers, it seems as though diets containing meat & bone meal tend to be 4thlimiting in valine while those containing poultry by-product meal are more likely to be 4th limiting in isoleucine. However, in a paper by Corzo et al. (2008b) it was suggested that isoleucine was fourth limiting in a meat and bone meal diet. As such, it is clear that due to the co-limitation between the these two branched chain amino acids, minor changes in the minimum constraint of either, within feed formulation software, can change the dynamics and thus the order of limitation. In reality, and because of the co-limitation issue, in order to fully optimize broiler performance, such as body weight gain and feed conversion, levels for both digestible valine and digestible isoleucine need to be near their requirement. Corzo et al.(2004a,b, 2010) has shown the requirement for both amino acids to be higher than NRC (1994) recommendations.

1Average of body weight gain and feed conversion estimates.

An observation of particular note across several publications is the response in breast meat weight and/or yield from an increased or optimal isoleucine level (Kidd et al., 2000; Kidd et al., 2004; Campos et al., 2009a; Berres et al., 2010; Corzo et al., 2010; Helmbrecht et al., 2010; Dozier et al., 2011; Mejia et al., 2011). Therefore, in markets where white meat is the primary goal of broiler production, emphasis should not only be placed to assure methionine, lysine and threonine equirements are met, but also that levels for digestible valine and perhaps especially digestible isoleucine are met as well. If the concept of ideal protein is used in formulation, setting appropriate ratios on these next two limiting amino acids will assure an adequate pool of amino nitrogen is available for de novo synthesis.

In the near future it may become common practice for commercial broiler diets to contain L-valine and L-isoleucine, in addition to methionine, lysine, and threonine sources. As more supplemental amino acids enter formulation a concomitant decrease in soybean meal occurs. In this scenario, and in particular all vegetable diets, glycine seems to be semiessential deeming a glycine + serine minimum to be set in least cost formulation. Chick glycine + serine needs range from just over 2% (Waguespack et a., 2009) to almost 2.5% (Dean et al., 2006). This effect does not seem to necessitate a nonessential nitrogen need as the efficiency of glycine + serine in low crude protein diets in chicks was not spared by dietary addition of L-glutamic acid or nitrogen (Waguespack et a., 2009). In addition to protein pool supply, glycine is a precursor of glutathionine peroxidase , nucleic acids, creatine, heme, bile, and it serves as a methyl source Reeds and Mersmann, 1991). In order to effectively reduce crude protein with the commercially available amino acids, glycine interrelationship to threonine, betaine, and enzymes warrants attention.

1Average of body weight gain and feed conversion estimates

V. PRACTICAL USE OF COMMERCIALLY AVAILABLE AMINO ACIDS

As each synthetic amino acid has reached the marketplace, there has been a period of uncertainty towards its’ full adoption within practical formulation. Some of this is driven from economics of inclusion based upon least-cost feed formulation, while other reasons have been based upon lack of requirement knowledge and/or concern of reducing the crude protein of the diet excessively. This scenario existed for DL-methionine, L-lysine HCl and most recently L-threonine. It has taken approximately 25 to 30 years for L-threonine to reach a significant market penetration and it will most likely take a decade or more before L-valine is fully adopted as well. With feed grade L-tryptophan already being commercially available, perhaps there will come a day when L-isoleucine and L-arginine are also economical to incorporate into broiler diets. From an environmental standpoint, the inclusion of each subsequent amino acid allows for formulating closer to the bird’s requirement, which reduces amino acid overages. This leads to a reduction in nitrogen pollution and a likely reduction in the amount of nitrous oxide produced, which provides a significant portion of the CO2 equivalence in greenhouse gas output.

REFERENCES

Azzam MMM, Zou XT, Dong SY, Xie P (2011) Poultry Science 90, 2251-2256.

Berres J, Vieira SL, Dozier WA III, Cortes MEM, de Barros R, Nogueira ET Kutschenko M (2010) Journal of Applied Poultry Science 19, 68-79.

Bertolo RFP, Chen ZL, Law, G, Pencharz PB, Ball, RO (1998) Journal of Nutrition 128, 1752-1759.

Bray DJ, Garlich JD (1960) Poultry Science 39, 1346-1349.

Campos A, Nogueira ET, Albino LF, Rostagno H (2009a) Poultry Science Annual Meeting, Raleigh, NC. Poster 351.

Campos A, Nogueira ET, Albino LF, Rostagno H (2009b) Poultry Science Annual Meeting, Raleigh, NC. Poster 352.

Corzo A, Dozier WA III, Kidd MT (2008a) Poultry Science 87, 335-338.

Corzo A, Dozier WA III, Kidd MT, Hoehler, D (2008b) International Journal of Poultry Science. 7 (6), 526-529.

Corzo A, Dozier WA III, Loar RE II, Kidd MT, Tillman PB (2009a) Journal of Applied Poultry Research 18, 237-243.

Corzo A, Dozier WA III, Loar RE II, Kidd MT, Tillman PB (2010) British Poultry Science 51 (4) 558-563.

Corzo A, Dozier WA III, Mejia L, Zumwalt CD, Kidd MT, Tillman, PB (2011) Journal of Applied Poultry Science 20:284-290.

Corzo A, Kidd MT, Dozier WA III, Vieira, SL (2007a) Journal of Applied Poultry Science16, 546-554.

Corzo A, Kidd,MT, Dozier WA III, Pharr GT, Koutsos, EA (2007b) Journal of Applied Poultry Research 16, 574-582.

Corzo A., Loar RE II. Kidd MT (2009b) Poultry Science 88, 1934-1938.

Corzo A, Moran ET Jr., Hoehler, D (2004a ) Arch. Geflugelk 68 (5), 194-198.

Corzo A, Moran ET Jr., Hoehler D (2004b) Poultry Science 83, 946-951.

Dean DW, Bidner TD, Southern LL (2006) Poultry Science 85, 288-296.

Dozier WA III, Corzo A, Loar RE II, Kidd MT, Tillman PB (2011) British Poultry Science 52 (2), 238-244.

Dozier WA III, Moran ET Jr, Kidd MT (2000) Journal of Applied Poultry Research 9, 214-222.

Everett DL, Corzo A, Dozier WA III, Tillman PB, Kidd, MT (2010) Journal of Applied Poultry Research 19, 321-326

Goodgame S, Coto C, Mussini F, Lu C, Karimi A, Yuan J, Waldroup P ( 2011),International Poultry Scientific Forum 2011, Abstract P217, 30.

Harms RH, Douglas CR, Waldroup PW (1962) Poultry Science 41, 805-812.

Harms RH, Waldroup PW (1963) British Poultry Science 4, 267-273.

Helmbrecht A, de Castro Tavernari F, Rostagno HS, Teixeira Albino LF, Lemme A (2010) Proceedings from the XIIIth European Poultry Conference. Poster Session I, 356-360. Tours, France. August 23-27th. http://www.epc2010.org/

Hutton RF (1958) Feedstuffs, Sep. 27, Oct. 4, Oct. 11, Oct. 18, Oct. 25, Nov. 1, and Nov. 8.

Hutton RF, King GA, Boucher RV (1958) USDA-ARS Pennsylvania Agriculture Experiment Station Production Research Report Number 20, Washington, DC USA.

Kidd MT, Barber SJ, Virden WS, Dozier WA III, Chamblee DW, Wiernusz (2003) Journal Applied Poultry Research 12, 115-123.

Kidd MT (1999) Australian Poultry Science Symposium, 16-22.

Kidd MT (2000) World’s Poultry Science Journal 56, 139-151.

Kidd MT, Kerr BJ (1997) Journal of Applied Poultry Research 6, 362-367.

Kidd MT, Burnham DJ, Kerr BJ (2004) British Poultry Science 44 (1), 67-75.

Kidd MT, Hackenhaar L (2005) CAB Reviews 1, 1-6.

Kidd MT, Kerr BJ, Allard JP, Rao SK, Halley, JT (2000) Journal of Applied Poultry Research 9, 223-233.

Kidd MT, Lerner SP, Allard JP, Rao SK, Halley JT (1999) Journal of Applied Poultry Research 8, 160-169.

Leclercq,B (1998) Poultry Science 77, 118-123.

Mejia L, Zumwalt CD, Kim EJ, Tillman PB, Corzo, A (2011) Journal of Applied Poultry Science 20, 485-490.

Moran ET Jr. (2011) Australian Poultry Science Symposium, 22-29.

National Research Council (1994) Nutrient Requirements of Poultry. 9th Revision Edition edited by National Academy Press, Washington, D.C. USA.

Neutra MR, Forstner JR (1987) Physiology of the Gastrointestinal Tract (Johnson, LR, ed.), 975-1009. Raven Press, New York, NY USA.

Penz AM Jr, Colnago GL, Jensen, LS (1997) Journal of Applied Poultry Research 6, 355-361.

Reeds PJ and Mersmann HJ (1991) Journal of Animal Science 69, 1532-1550.

Robbins KR (1987) Poultry Science 66, 1531.

Rodehutscord M, Fatufe AA (2005). Proceedings of the 15th European Symposium on Poultry Nutrition, World's Poultry Science Association. Balatonfüred, Hungary. September 25-29. 545-547.

Smith NK, Jr, Waldroup PW (1988) Poultry Science 67, 108.

Thomas OP, Farran M, Tamplin CB, Zuckerman AL ( 1987) Proceedings of the Maryland Nutrition Conference, 38.

Thomas OP, Twining PV Jr., Bossard EH, Nicholson JL, Rubin, M (1979) Proceedings of the Maryland Nutrition Conference, 44.

Thomas OP, Zuckerman AI, Farran M, Tamplin, CB (1986) Proceedings of the Maryland Nutrition Conference, 79.

Thornton PA, Blaylock LG, Moreng RE (1957) Poultry Science 36, 552-557.

Thornton SA, Corzo A, Pharr GT, Dozier,WA III, Miles DM, Kidd, MT (2006) British Poultry Science 47 (2), 190-199.

Tillman PB (2011) III International Symposium on Nutritional Requirements of Poultry and Swine. Vicosa, Brazil, March 29-31, 21-44

Uzu G (1986) AEC Information Poultry 252, 03600 Commentry, France.

Waguespack AM, Powell S, Bidner TD, Southern, LL (2009) Journal of Applied Poultry Research 18, 761-765.

Waugh FV (1951) Journal of Farm Economics 33, 299-310.

Webel DM, Fernandez SR, Parsons CM, Baker, DH (1996) Poultry Science 75, 1253-1257.

Wu, G (1998) Journal of Nutrition 128, 1249-1252.

Azzam MMM, Zou XT, Dong SY, Xie P (2011) Poultry Science 90, 2251-2256.

Berres J, Vieira SL, Dozier WA III, Cortes MEM, de Barros R, Nogueira ET Kutschenko M (2010) Journal of Applied Poultry Science 19, 68-79.

Bertolo RFP, Chen ZL, Law, G, Pencharz PB, Ball, RO (1998) Journal of Nutrition 128, 1752-1759.

Bray DJ, Garlich JD (1960) Poultry Science 39, 1346-1349.

Campos A, Nogueira ET, Albino LF, Rostagno H (2009a) Poultry Science Annual Meeting, Raleigh, NC. Poster 351.

Campos A, Nogueira ET, Albino LF, Rostagno H (2009b) Poultry Science Annual Meeting, Raleigh, NC. Poster 352.

Corzo A, Dozier WA III, Kidd MT (2008a) Poultry Science 87, 335-338.

Corzo A, Dozier WA III, Kidd MT, Hoehler, D (2008b) International Journal of Poultry Science. 7 (6), 526-529.

Corzo A, Dozier WA III, Loar RE II, Kidd MT, Tillman PB (2009a) Journal of Applied Poultry Research 18, 237-243.

Corzo A, Dozier WA III, Loar RE II, Kidd MT, Tillman PB (2010) British Poultry Science 51 (4) 558-563.

Corzo A, Dozier WA III, Mejia L, Zumwalt CD, Kidd MT, Tillman, PB (2011) Journal of Applied Poultry Science 20:284-290.

Corzo A, Kidd MT, Dozier WA III, Vieira, SL (2007a) Journal of Applied Poultry Science16, 546-554.

Corzo A, Kidd,MT, Dozier WA III, Pharr GT, Koutsos, EA (2007b) Journal of Applied Poultry Research 16, 574-582.

Corzo A., Loar RE II. Kidd MT (2009b) Poultry Science 88, 1934-1938.

Corzo A, Moran ET Jr., Hoehler, D (2004a ) Arch. Geflugelk 68 (5), 194-198.

Corzo A, Moran ET Jr., Hoehler D (2004b) Poultry Science 83, 946-951.

Dean DW, Bidner TD, Southern LL (2006) Poultry Science 85, 288-296.

Dozier WA III, Corzo A, Loar RE II, Kidd MT, Tillman PB (2011) British Poultry Science 52 (2), 238-244.

Dozier WA III, Moran ET Jr, Kidd MT (2000) Journal of Applied Poultry Research 9, 214-222.

Everett DL, Corzo A, Dozier WA III, Tillman PB, Kidd, MT (2010) Journal of Applied Poultry Research 19, 321-326

Goodgame S, Coto C, Mussini F, Lu C, Karimi A, Yuan J, Waldroup P ( 2011),International Poultry Scientific Forum 2011, Abstract P217, 30.

Harms RH, Douglas CR, Waldroup PW (1962) Poultry Science 41, 805-812.

Harms RH, Waldroup PW (1963) British Poultry Science 4, 267-273.

Helmbrecht A, de Castro Tavernari F, Rostagno HS, Teixeira Albino LF, Lemme A (2010) Proceedings from the XIIIth European Poultry Conference. Poster Session I, 356-360. Tours, France. August 23-27th. http://www.epc2010.org/

Hutton RF (1958) Feedstuffs, Sep. 27, Oct. 4, Oct. 11, Oct. 18, Oct. 25, Nov. 1, and Nov. 8.

Hutton RF, King GA, Boucher RV (1958) USDA-ARS Pennsylvania Agriculture Experiment Station Production Research Report Number 20, Washington, DC USA.

Kidd MT, Barber SJ, Virden WS, Dozier WA III, Chamblee DW, Wiernusz (2003) Journal Applied Poultry Research 12, 115-123.

Kidd MT (1999) Australian Poultry Science Symposium, 16-22.

Kidd MT (2000) World’s Poultry Science Journal 56, 139-151.

Kidd MT, Kerr BJ (1997) Journal of Applied Poultry Research 6, 362-367.

Kidd MT, Burnham DJ, Kerr BJ (2004) British Poultry Science 44 (1), 67-75.

Kidd MT, Hackenhaar L (2005) CAB Reviews 1, 1-6.

Kidd MT, Kerr BJ, Allard JP, Rao SK, Halley, JT (2000) Journal of Applied Poultry Research 9, 223-233.

Kidd MT, Lerner SP, Allard JP, Rao SK, Halley JT (1999) Journal of Applied Poultry Research 8, 160-169.

Leclercq,B (1998) Poultry Science 77, 118-123.

Mejia L, Zumwalt CD, Kim EJ, Tillman PB, Corzo, A (2011) Journal of Applied Poultry Science 20, 485-490.

Moran ET Jr. (2011) Australian Poultry Science Symposium, 22-29.

National Research Council (1994) Nutrient Requirements of Poultry. 9th Revision Edition edited by National Academy Press, Washington, D.C. USA.

Neutra MR, Forstner JR (1987) Physiology of the Gastrointestinal Tract (Johnson, LR, ed.), 975-1009. Raven Press, New York, NY USA.

Penz AM Jr, Colnago GL, Jensen, LS (1997) Journal of Applied Poultry Research 6, 355-361.

Reeds PJ and Mersmann HJ (1991) Journal of Animal Science 69, 1532-1550.

Robbins KR (1987) Poultry Science 66, 1531.

Rodehutscord M, Fatufe AA (2005). Proceedings of the 15th European Symposium on Poultry Nutrition, World's Poultry Science Association. Balatonfüred, Hungary. September 25-29. 545-547.

Smith NK, Jr, Waldroup PW (1988) Poultry Science 67, 108.

Thomas OP, Farran M, Tamplin CB, Zuckerman AL ( 1987) Proceedings of the Maryland Nutrition Conference, 38.

Thomas OP, Twining PV Jr., Bossard EH, Nicholson JL, Rubin, M (1979) Proceedings of the Maryland Nutrition Conference, 44.

Thomas OP, Zuckerman AI, Farran M, Tamplin, CB (1986) Proceedings of the Maryland Nutrition Conference, 79.

Thornton PA, Blaylock LG, Moreng RE (1957) Poultry Science 36, 552-557.

Thornton SA, Corzo A, Pharr GT, Dozier,WA III, Miles DM, Kidd, MT (2006) British Poultry Science 47 (2), 190-199.

Tillman PB (2011) III International Symposium on Nutritional Requirements of Poultry and Swine. Vicosa, Brazil, March 29-31, 21-44

Uzu G (1986) AEC Information Poultry 252, 03600 Commentry, France.

Waguespack AM, Powell S, Bidner TD, Southern, LL (2009) Journal of Applied Poultry Research 18, 761-765.

Waugh FV (1951) Journal of Farm Economics 33, 299-310.

Webel DM, Fernandez SR, Parsons CM, Baker, DH (1996) Poultry Science 75, 1253-1257.

Wu, G (1998) Journal of Nutrition 128, 1249-1252.

This paper was presented at the 23rd Annual Australian Poultry Science Symposium, Sydney, New South Wales, February 19-22, 2012 organized by the Poultry Research Foundation (University of Sidney) and the World´s Poultry Science Association (Australian Branch). Engormix.com thanks the University, the WPSA and the authors for this huge contribution.

Content from the event:

Related topics:

Authors:

University of Arkansas (USA)

Recommend

Comment

Share

Recommend

Reply

28 de agosto de 2012

This article helped a lot. Also importers and distributors of amino acids used currently in the market today will have idea on what will be the products they will focuse in the near future.

Recommend

Reply

Would you like to discuss another topic? Create a new post to engage with experts in the community.

.jpg&w=3840&q=75)