Fish Feed Storage

The use of potassium diformate-based preservatives as storage control for industrial fish

Published: May 27, 2011

By: Christian Lückstädt

Almost one-third of the world fish harvest is not used for direct human consumption, but is converted into fish meal or fish oil for further application in animal feed. Therefore, about 25 million tonnes of fish are annually handled and processed in ways other than fresh, frozen, smoked or canned which are eaten (Balios, 2003). The supply of huge volumes of high quality fish meal is necessary to supply the rapid growing aquaculture industry, which is growing with around 10% annually (FAO). The amount of high quality fish meal of the total amount of fish meal is expected to grow from 8% to 50% during the next 30 years (Hydro Norway, 2000).

Acid preservation of fish and fish viscera to produce fish silage has been a common practice and its final product has been widely used in fish feeds with reported beneficial effects (Gildbert and Raa, 1977; Åsgård and Austreng, 1981). It is a widely used method in many European countries to preserve fish-by-products as well as freshly caught "industrial fish" for further fish meal or fish oil production with formic acid or potassium diformate in order to prolong fishing time or to extend the storage duration of those fish.

Since there is growing interest onto preservation of fish in the "booming" aquaculture regions of South East Asia in order to preserve fish waste, by-catch and surplus fish as well, trials needed to be carried out, which adapt to those situations. Therefore a trial was designed to store fish (sardines) at higher temperatures.

The present study examined the effectiveness of a liquid acid salt, based on ADDCON´s diformate technology (Fishform Plus) as a preservative of sardines at different elevated temperatures (9.8°C and 15.7°C). The blend was added in 4 different concentrations (0.250%, 0.375%, 0.500% and 0.625%) next to a negative control. Furthermore, an additional treatment level of 0.750% was stored at 15.7°C. At day zero samples of the sardines were taken for Total Volatile Nitrogen (TVN) analysis prior to distribution into the storage containers.

Acid preservation of fish and fish viscera to produce fish silage has been a common practice and its final product has been widely used in fish feeds with reported beneficial effects (Gildbert and Raa, 1977; Åsgård and Austreng, 1981). It is a widely used method in many European countries to preserve fish-by-products as well as freshly caught "industrial fish" for further fish meal or fish oil production with formic acid or potassium diformate in order to prolong fishing time or to extend the storage duration of those fish.

Since there is growing interest onto preservation of fish in the "booming" aquaculture regions of South East Asia in order to preserve fish waste, by-catch and surplus fish as well, trials needed to be carried out, which adapt to those situations. Therefore a trial was designed to store fish (sardines) at higher temperatures.

The present study examined the effectiveness of a liquid acid salt, based on ADDCON´s diformate technology (Fishform Plus) as a preservative of sardines at different elevated temperatures (9.8°C and 15.7°C). The blend was added in 4 different concentrations (0.250%, 0.375%, 0.500% and 0.625%) next to a negative control. Furthermore, an additional treatment level of 0.750% was stored at 15.7°C. At day zero samples of the sardines were taken for Total Volatile Nitrogen (TVN) analysis prior to distribution into the storage containers.

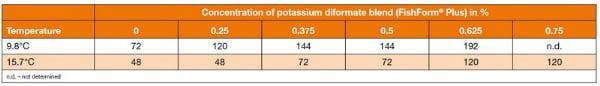

Table 1: Time in hours until the 80 mg TVN limit per 100 g sardines is reached at different temperatures with or without acid-treatment

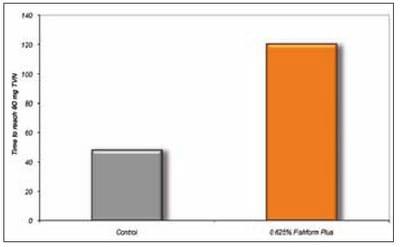

At both temperatures the pH levels of the treated sardines were lower than the control (see table 1) - the lowest pH being on the highest concentration of preservative. Within treatments, once stabilised there were no significant changes in the pH-level. The overall Total Volatile Nitrogen level at the start of the experiment was 36.2 mg / 100 g fish. Values in the control increased rapidly and exceeded already 80 mg after 72 hours at 9.8°C storage temperature, while they reached the same level after only 48 hours at 15.7°C. At both temperatures the fast TVN development was delayed by the addition of the potassium diformate blend. This delay was however dosage dependent. At 9.8°C it took 120 hours to exceed 80 mg TVN per 100 g fish material with 0.25%, 144 hours with 0.375% and 0.5%, while it took 192 hours to reach the limit of 80 mg TVN if the fish was stored with 0.625% of the potassium diformate blend. Comparable time periods at 15.7°C were 48 h, 72 h, 72 h and 120 h (figure 1).

Fig. 1: Time to reach 80 mg TVN / 100 g fish with or without Fishform Plus at 16°C

TVN is often used as a criterion for the freshness of fish raw material (Haaland and Njaa, 1987). This value in the fish before processing is known as the most important quality criteria for raw industrial fish. The main constituents of TVN are trimethylamine and ammonia. Its amount increases with time of storage in the unfrozen state. Trimethylamine originates from bacterial decomposition, and the presence in fish is therefore taken as an indication for bacterial growth, while the ammonia comes from breaking amino acids - thus reducing the quality of the available protein. Levels of 40 to 80 mg TVN per 100 g fish mass are regarded by the industry as limits for a good quality fish meal for instance.

Conclusions

The determined results clearly indicate that due to the addition of a potassium diformate blend an extension of the storage period of fish can be achieved, even under high temperatures - indicating the storage without ice. The storage period for sardines added 0.625% potassium diformate blend or higher was 2.5 times longer than that for the control at both temperatures and is reaching either 8 or 5 days for storage temperatures of around 10°C and 16°C respectively. In case the storage of the trash fish or by-catch is done without any cooling at the high temperatures in tropical Asia, it seems necessary to increase the recommended dosage to 1%. This is a very important finding, since many fish landing places in rural areas of South East Asia are often lacking appropriate cooling devices or possibilities. Further trials with such an increased dosage, which have been recently carried out in Thailand and the Philippines at temperatures even above 20°C, strongly support these results.

Related topics:

Authors:

ADDCON

Recommend

Comment

Share

ADDCON

16 de junio de 2011

Dear Mr. Tan,

ADDCON is the producer and supplier of the potassium diformate blend. It is produced in our factory in Norway and supplied from ADDCON Asia, via distributors for instance in Thailand, Vietnam, Malaysia, Indonesia and the Philippines.

Recommend

Reply

16 de junio de 2011

would like to know the actual manufacturer of potassium diformate and interested in distributing in the region

Recommend

Reply

Would you like to discuss another topic? Create a new post to engage with experts in the community.

.jpg&w=3840&q=75)