Introduction

Decisions concerning the milking center are some of the most complicated decisions a dairy producer has to make. Milking procedures, herd size, expansion plans, milking interval and the equity position of a producer influence these decisions. One parlor will not meet the needs of all dairy producers. Producers will have to make the following decisions before they can select or develop management protocols for a milking parlor:

1. How many cows will be milked through the parlor?

2. Will the parlor need to be expanded in the future?

3. What milking procedure will be used (minimal or full)?

4. If a full milking routine; how much contact time do you want (strips per teat)?

5. Which milking routine will be used (sequential, grouping, territorial)?

6. Are you willing to train teams of milkers to operate large parallel or herringbone parlors?

This paper will discuss the factors to consider when selecting a new parlor or managing an existing parlor. It is essential that dairy producers develop accurate time budgets for the milking procedures and routines they select.

Options for Milking Procedures and Routines in Parallel and Herringbone Parlors Before the options for milking procedures and routines can be discussed the following terms must be defined:

Prep time–time taken to manually clean and dry the teat surface

Contact time–the actual time spent manipulating/touching teats and is the source of stimulation for oxytocin release.

Prep-lag time-time between the beginning of teat preparation to the application of the milking machine.

Milking Procedures–the individual events (i.e. strip, pre-dip, wipe, attach) required to milk a single cow.

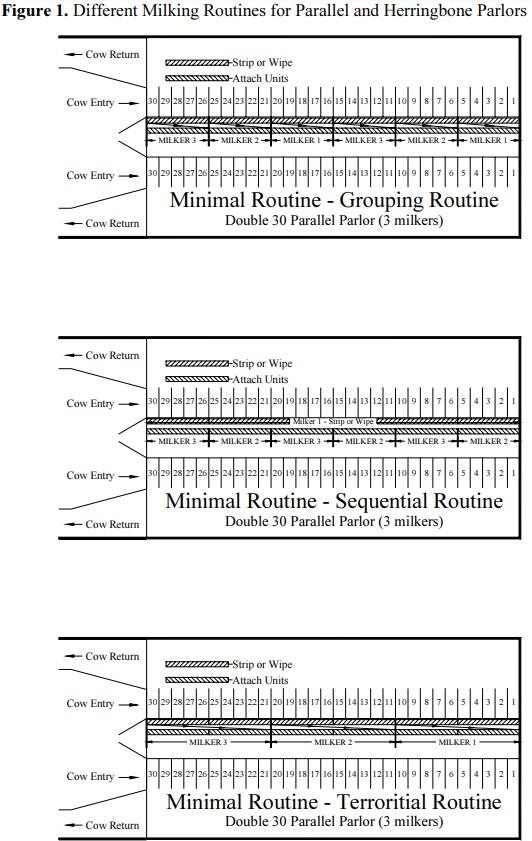

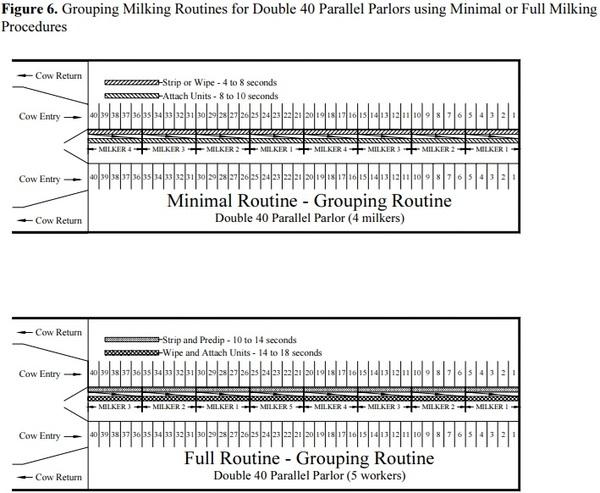

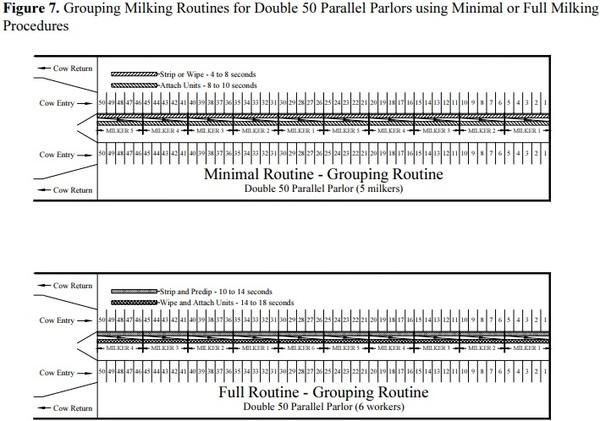

Milking Routines–define how an individual milker or a group of milkers carry out a given milking procedure (minimal or full) over multiple cows. In parallel and herringbone parlors; there are three predominant milking routines (grouping, sequential, and territorial). These individual milking routines are drawn in Figure 1.

Grouping Milking Routine–In a grouping routine the operator will perform all the individual tasks of the milking procedure on 4-5 cows. Once they have completed a group of cows they move to the next group of available cows.

Sequential Milking Routine–Operators using a sequential routine split up the individual tasks of the milking procedure between operators and work as a team. Operators work as a team following each other performing their individual tasks.

Territorial Milking Routine–Milkers are assigned units on both sides of the parlor and only operate the units assigned to them. When a territorial routine is used milkers are not dependent on other milkers to perform specific tasks.

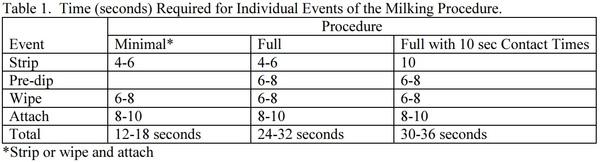

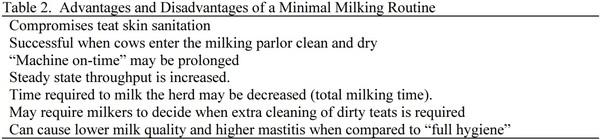

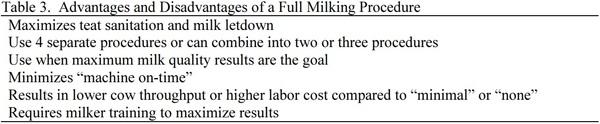

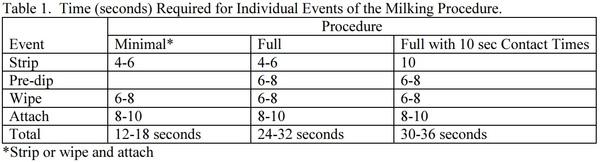

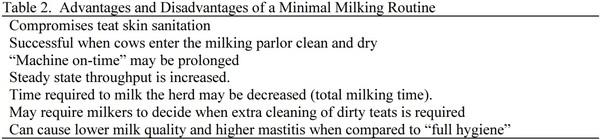

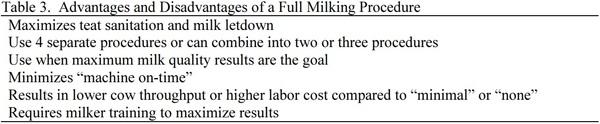

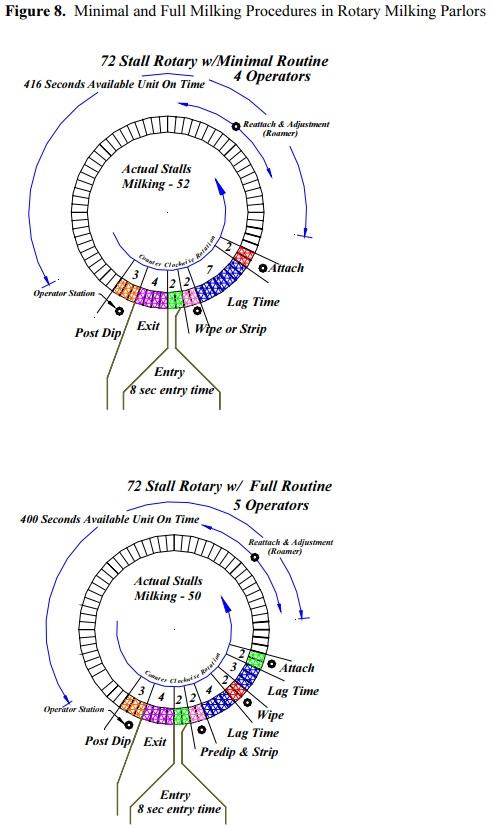

The predominant milking procedures are minimal (strip or wipe and attach) and full (pre-dip, strip, wipe and attach). Full milking procedures impact the number of cows per stall per hour in parallel, herringbone and rotary parlors. In large parallel and herringbone parlors cows per stall per hour are 5.2 when minimal milking procedures are used and 4.4 when full milking procedures are used. In rotary parlors cows per stall per hour decline from 5.75 to 5.3 when a minimal routine is used as compared to a full routine (Armstrong et al. 2001). In large parlors milking procedures have a dramatic impact on the number of units one operator can handle in parallel and herringbone parlors. In 1997, Smith et al. published guidelines for the number of units that one operator could handle using a minimal and a full milking procedures. When a full milking procedure was used a milker could operate 10 units per side and 17 units per side when using minimal milking procedures. These recommendations were based on allowing 4-6 seconds to strip a cow and attaching all the units on one side of the parlor in 4 minutes. In recent years several milking management specialists have been recommending 2-3 squirts per teat (8-10 seconds) when stripping cows to increase stimulation and promote better milk letdown. Some of these management specialists believe that increasing the amount of stimulation reduces unit on times. At this time a strong data set supporting this theory does not exist. An AABP research update reported by Rapnicki, Stewart, and Johnson (2002) indicates that milk flow rate was decreased when cows that had been previously stripped were no longer stripped. If this is implemented, producers will have to reduce the number of units one operator can manage per side (Table 1). The sequencing of the individual events of the milking procedure is critical. Work completed by Rasmussen et al. (1992) would indicate an ideal prep-lag time of 1minute and 18 seconds. Prep-lag times of 1-1.5 minutes seem to be accepted as optimal for all stages of lactation. Producers will have to decide which milking procedure they will use and the amount of stimulation. Some of the advantages and disadvantages of minimal and full milking procedures are listed in Tables 2 and 3.

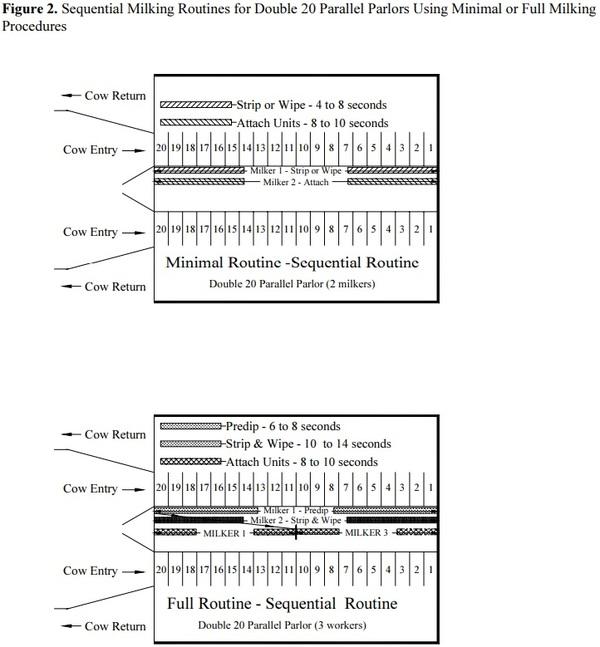

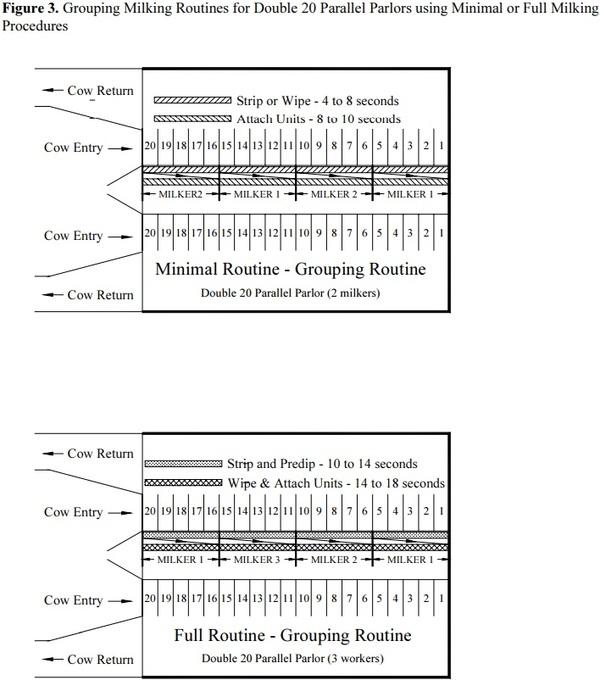

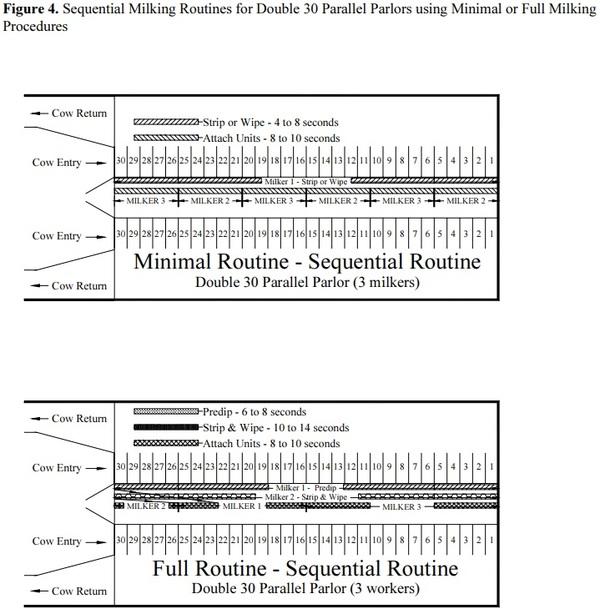

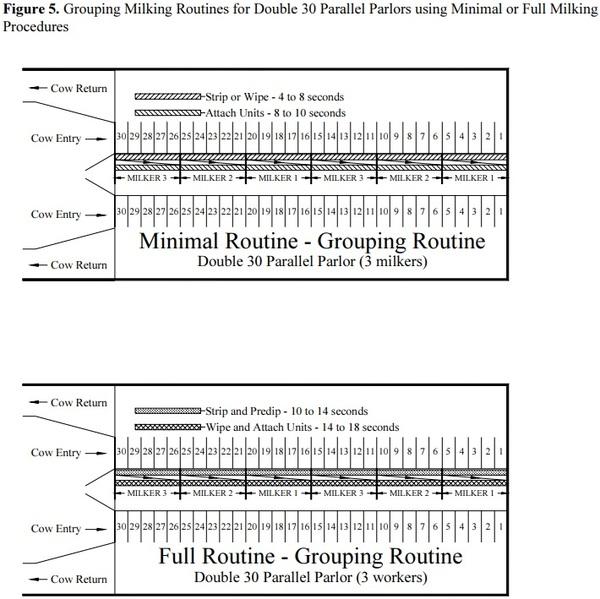

Three predominant milking routines are used in parallel and herringbone parlors (sequential, grouping, and territorial). These milking routines are presented in Figure 1. The use of territorial routines will reduce throughput 20-30% when compared to sequential routines (Smith et al. 1997). Grouping routines seem to be an alternative to sequential routines without sacrificing throughput. Sequential and grouping routines are demonstrated in Figures 2-7. Both full and minimal milking procedures in rotary parlors are presented in Figure 8.

Impact of Automatic Take-offs

A study published by Stewart et al. (2002) would indicate that when automatic cluster remover settings were increased, average milking duration was reduced 10.2 to 15.6 seconds per cow. Higher automatic cluster remover settings did not have a negative impact on milk production per cow. Average milk flow per minute increased .11 to .42 lb/minute. Increasing automatic cluster remover settings represents an opportunity to increase parlor performance.

Selecting Parlor Type

Dairy owners usually have a personal preference for a certain parlor type. Many times this personal preference conflicts with the number of cows to be milked, length of the milking shift, anticipated milk quality, udder health results and financial resources. The selection of a milking parlor should be influenced by the initial herd size, expansion plans, economic impact on the dairy, and the ability to train and manage employees. Dairy producers should visit as many types of parlors as possible and make a final decision after having an opportunity to review all types, not just the fastest or newest.

Total Hours of Use

A milking parlor sized for use only 4 to 6 hours a day will be more expensive to build and operate per cow than if the parlor operates 20 to 21 hours per day. For example, a 250-cow dairy, milking two times a day could be milked in a double-4 herringbone parlor in a 6-hour shift, or milked in a double-10 herringbone in a 3-hour shift. The cost of a double-4 is approximately $90,000, while a double-10 is $180,000. Fewer hours of use may be desirable if farm personnel also have other duties, such as crop production, feeding, animal health, and raising replacements. However, a larger return on investment will be realized if the milking parlor can be used 20 to 21 hours a day to milk cows. Producers are often caught making a choice between the number of cows they can milk and which milking procedure they can use under these conditions. If they are not careful milk quality and udder health may suffer.

Number of Operators

The number of operators may be influenced by the availability of personnel, milking procedure or herd size. Most small herringbone and parallel parlors (D-4 to D-12) are operated by one operator. One person parlors are more efficient in the number of cows per labor hour. Two-or-more-operator parallel or herringbone parlors have the advantage of continuous operation even during group change, when one operator is late for the milking shift, or when a short emergency requires one operator to leave the parlor. The disadvantage is that is it more difficult for the owner to assess operator performance or quality standards, and the number of cows per labor hour will be less. However, many producers are able to achieve the same labor efficiency in multiple operator parlors as single operator parlors with training and monitoring programs.

Initial Herd Size and Expansion Plans

Dairy producers will want to consider their current herd size along with plans to increase herd size in the future. If a producer wants to grow in steps, parallel or herringbone parlors can be constructed to allow for expansion as herd size increases. Parallel and herringbone parlors have an advantage over rotary parlors that can not be expanded in steps.

One vs Two Parlors

Some research indicates that two smaller parlors are more efficient than one larger parlor (Thomas et al. 1993, 1994, 1995). One study compared two double 20 parallels versus one double 40 parallel (Thomas et al.1995). The net parlor return over 15 years was $908,939 greater in the two smaller parlors vs. one large parlor. The initial cost of constructing two double 20 parallels was $22,227 higher than constructing one double 40. Constructing 2 parlors also allows producers to construct the dairy in phases and increase the number of groups of lactating cows.

Training and Monitoring Milkers

Providing training and monitoring milkers is a constant challenge for dairy producers. In parallel and herringbone parlors with multiple milkers it becomes very important to train teams of milkers to work together to improve parlor performance. In parallel and herringbone parlors operators are mobile and able to perform multiple tasks (i.e. strip, pre-dip, wipe, attach) as compared to rotary parlors where operators are fixed in one location and only perform one or two tasks in this location. If the performance of multiple operator parallel and herringbone parlors is to be maximized, operators will have to work together to perform the milking procedures over multiple cows using a grouping or sequential milking routine. After milker training has been completed producer will have to monitor the performance of individual milkers and parlor performance.

Evaluating Parlor Performance

Milking parlor performance has been evaluated by time and motion studies (Armstrong and Quick, 1986) to measure steady-state throughput (cows per hour). Steady-state throughput does not include time for cleaning the milking system, maintenance of equipment, effects of group changing, and milking the hospital strings. These studies also allow us to look at the effect of different management variables on milking parlor performance. Historically this information has been used to size milking parlors to meet dairy producer needs.

Sizing Milking Parlors

As the size of dairies increases the sizing of milking parlors becomes more complicated. Many producers are choosing to use hospital parlors reducing pressure on the main parlor. Some producers are also milking healthy cows through the hospital parlor so additional cows can be milked through the main parlor or parlors. Some dairies are increasing the number of milkings to 4, 5, or 6 times a day for the first 21-42 days of lactation and returning to 2 or 3 times a day milking at 21-42 days in milk (Dahl 2002). These factors will have a dramatic impact on how the milking parlor is sized. Sizing parallel, herringbone, and rotary parlors is discussed below. In the discussion below it is assumed that all groups of cows will be milked through the main parlor.

Sizing Parallel and Herringbone Milking Parlors

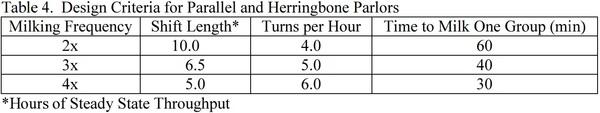

The design criteria for parallel and herringbone parlors are presented in Table 4.

Typically, milking parlors are sized so that the herd can be milked once in 10 hours when milking 2x per day; 6.5 hours when milking 3x per day; and 5 hours when milking 4x per day. Using these criteria, the milking parlor will be sized to accommodate the cleaning and maintenance of the parlor. The facilities or cow groups are determined based on milking one group in 60 minutes when milking 2x, 40 minutes when milking 3x, and 30 minutes when milking 4x. Group size is adjusted to be divisible by the number of stalls on one side of the milking parlor. Having as many occupied stalls as possible per cycle maximizes parlor efficiency. The number of cows that will be milked per hour can be calculated using the following formulas:

Total # of stalls x turns per stall per hour = cows milked per hour (CPH)

Number of milking cows = CPH x milking shift length (hours)

Sizing Rotary Parlors

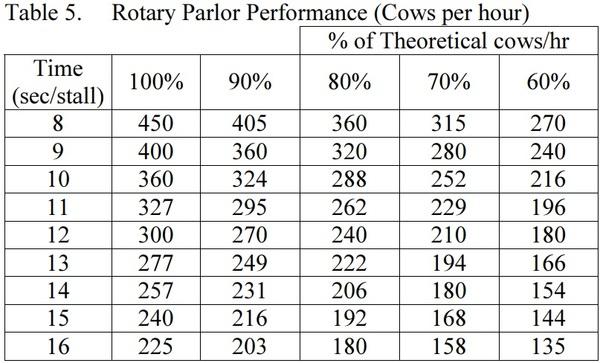

Entry time (seconds/stall), number of empty stalls, number of cows which go around a second time, entry and exit stops and the size of the parlor (number of stalls) influence the performance of rotary parlors. The entry time will determine the maximum number of cows that can be milked per hour. For example, if the entry time is 10 seconds, the maximum throughput will be 360 cows per hour (3600 seconds per hour / 10 seconds per stall = 360 cows per hour). This is referred to as theoretical throughput.

Theoretical throughput assumes that the parlor never stops, cows are milked out in 1 rotation and a new cow occupies every stall at entry. In reality, there are empty stalls, cows that go around a second time and times when the rotary table is stopped. Table 5 shows rotary parlor performance at different percentages of theoretical throughput. As the number of empty stalls, cows making a second trip around, and number of stops increases the percent of theoretical throughput is decreased.

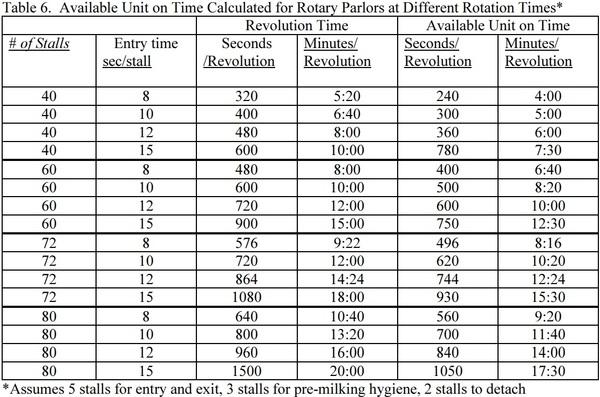

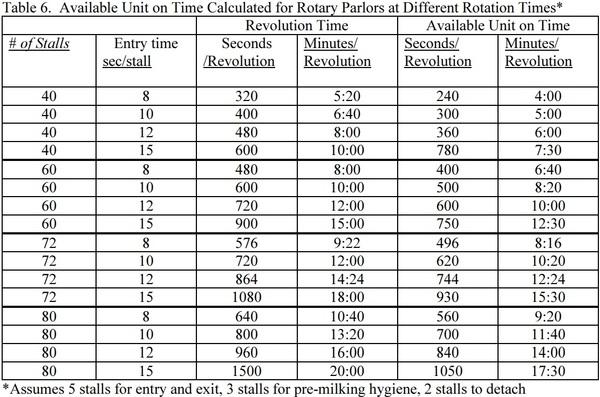

The number of stalls or size of the rotary parlor affects the available unit on time. Table 6 lists available unit on time for different sizes of rotary parlors at different rotation times. A rotary parlor must be large enough to allow approximately 90 percent of the cows to be milked out in one trip around the parlor.

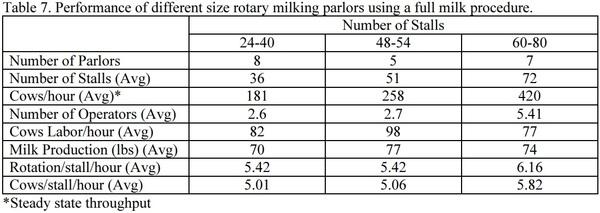

In reviewing the data available today, rotary parlor should be sized at an 11-12 seconds per stall rotation and 81% of theoretical throughput. The parlor should be large enough to allow 9 minutes of available unit on time. If you want size to rotary parlors on a steady state throughput basis, parlors below 54 stalls milk 5 cows/stall/hour and parlors 60 stalls or larger milk 5.8 cows/stall/hour (Table 7). The parlors with 60 stalls or larger are able to increase the number of rotations per hour and still maintain adequate time to milk cows out with out sending them around a second time. It is critical that rotary parlors be sized to accommodate some expansion because they are very difficult to expand.

Which Parlor is Right for Me?

The decisions that a dairy producer makes concerning the milking parlor can have a dramatic impact on their ability to meet their goals. One parlor type will not meet the needs of all dairy producers. Producers will need to carefully evaluate all options. The milking parlor is the center of the dairy. If a producer wants to grow in steps and expand the milking parlor as cows are added, constructing a parallel or herringbone parlor with the ability to add stalls in the future would be a logical choice. If the goal is to build a parlor to its final size and fill it full of cows, any of the milking parlor types could be used. Room could be allowed in the site plan to add a second milking parlor and additional cow housing. Whatever type and size of parlor is selected, it is absolutely critical that a financial evaluation is completed.

This article was published in the Proceedings of the 6th Western Dairy Management Conference.

.jpg&w=3840&q=75)