Kemin AgriFoods Asia presents its Quality Assurance laboratory

Published: October 1, 2010

Source : kemin AgriFoods Asia

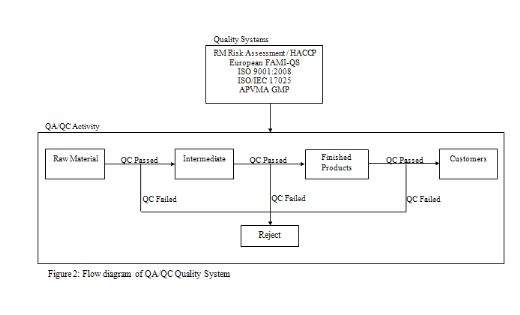

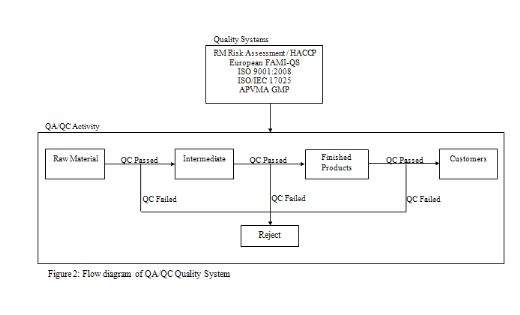

Kemin Agrifoods Asia, located in Singapore, has a QA/QC laboratory that ensures the products manufactured in the Singapore plant are of the highest quality. The laboratory is accredited and certified under the Singapore Accreditation Council-Singapore Laboratory Accreditations Scheme to ISO/IEC 17025:2005. Our experienced Quality professionals, with an average working year of more than 10 years each in Kemin Agrifoods Asia, ensured that all incoming raw materials, intermediate and finished goods are rigorously checked in accordance to ISO/IEC 17025:2005 standard (Figure 1). This Laboratory standard is recognized by the respective National Accreditation Board of the Asia Pacific Countries that Kemin Agrifoods Asia export to.

An example of this is one of our recently developed, patent pending new pigment products called Kem Glo ANA. It is an all natural antioxidant red pigment product. The oleoresin in this product is checked for, among other things dioxins and dioxins-like PCBs (polychlorinated biphenyls). The intermediate and finished product are checked in accordance with our Standard Operating Procedure (SOP) and adheres to the standard stipulated by ISO/IEC 17025:2005 (Figure 2).

Kemin is also certified under the ISO 9001:2008, the Australian Pesticides and Veterinary Medicines Authority (APVMA) Good Manufacturing Practices (GMP) and the European Feed Additives and PreMixture Quality System (FAMI-QS). We place feed safety as our highest priority by establishing a thorough risk assessment and Hazard Analysis Critical Control Point (HACCP) program (Figure 2) . Monthly audits are conducted in our manufacturing facility and our well established Critical Control Points and HACCP are regularly reviewed every 6 months to ensure that these stay relevant and updated.

Figure 1: The Quality Team of Kemin Agrifoods Asia.

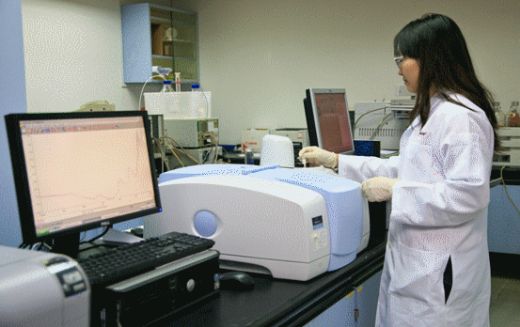

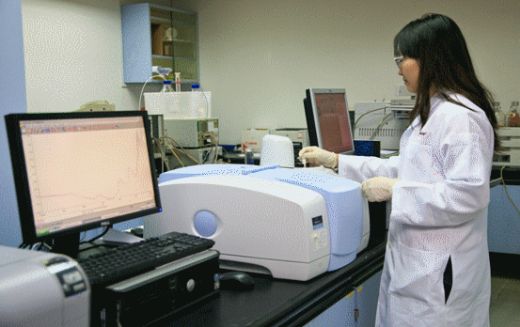

The quality and control of our production process is tracked, every batch, by using Statistic Process Control (SPC). This allows us to fine tune our production process and ensures every product made is up to the specifications. Our QA laboratory is well equipped with the latest state-of-the-art equipment, and allows analyses to be carried out round the clock (Figure 3). All of these equipment are regularly maintained to ensure optimal analyses and validation. We also have the capability of tracing all incoming raw materials from receipt through conversion to finished products. In addition, all our incoming raw materials, intermediate and finished products are retained as part of our quality assurance commitment to our customers.

Figure 3. QC Chemist analyzing a test sample using the FT-NIR.

Figure 3. QC Chemist analyzing a test sample using the FT-NIR.

Source

kemin AgriFoods AsiaRelated topics:

Mentioned in this news release:

Kemin Industries, Inc

Recommend

Comment

Share

Would you like to discuss another topic? Create a new post to engage with experts in the community.

_1.jpg&w=3840&q=75)