Recent Advances in the Bioherbicidal Potential of Tenuazonic Acid, an Alternaria spp. mycotoxin

1. Bordin, E.; Camargo, A.; Rossetto, V.; Scapini, T.; Modkovski, T.; Weirich, S.; Carezia, C.; Franceschetti, M.; Balem, A.; Golunski, S.; Galon, L.; Fuzinatto, C.; Fongaro, G.; Mossi, A.; Treichel, H. Ind. Biotechnol. 2018, 14, 157-163.

2. Rai, M.; Zimowska, B.; Shinde, S.; Tres, M. V. J. Appl. Microbiol. Biotechnol. 2021, 105, 3009-3018.

3. Moura, M. S.; Lacerda, J. W. F.; Siqueira, K. A.; Bellete, B. S.; Sousa, P. T.; Dall´Óglio, E. L.; Soares, M. A.; Vieira, L. C. C.; Sampaio, O. M. J. Environ. Sci. Health. 2020, 55, 470-476.

4. Brun, T.; Rabuske, J. E.; Luft, L.; Confortin, T. C.; Todero, I.; Aita, B. C.; Zabot, G. L.; Mazutti, M. A. Environ. Technol. 2020, 43, 2135-2144.

5. Abbas, T.; Zahir, Z. A.; Naveed, M.; Kremer, R. J., in: Advances in Agronomy, Vol. 147, DL Sparks, Ed., Academic Press, 2018, 239-280.

6. Bordin, E. R.; Frumi Camargo, A.; Stefanski, F. S.; Scapini, T.; Bonatto, C.; Zanivan, J.; Preczeski, K.; Modkovski, T. A.; Reichert Júnior, F.; Mossi, A. J.; Fongaro, G.; Ramsdorf, W. A.; Treichel, H. Biocatal. Biotransform. 2021, 39, 346-359.

7. Daniel, J. J.; Zabot, G. L.; Tres, M. V.; Harakava, R.; Kuhn, R. C.; Mazutti, M. A. Biocatal. Agric. Biotechnol. 2018, 14, 314-320.

8. Prosser, R. S.; Anderson, J. C.; Hanson, M. L.; Solomon, K. R.; Sibley, P. K. Agric., Ecosyst. Environ. 2016, 232, 59-72.

9. Ferreira, M. I.; Reinhardt, C. F. Afr. J. Agric. Res. 2016, 11, 450-459.

10. Souza, A. R. C. d.; Baldoni, D. B.; Lima, J.; Porto, V.; Marcuz, C.; Machado, C.; Ferraz, R. C.; Kuhn, R. C.; Jacques, R. J. S.; Guedes, J. V. C.; Mazutti, M. A. Braz. J. Microbiol. 2017, 48, 101-108.

11. Harding, D. P.; Raizada, M. N. Front. Plant Sci. 2015, 6.

12. Radhakrishnan, R.; Alqarawi, A. A.; Abd Allah, E. F. Ecotoxicol. Environ. Saf. 2018, 158, 131-138.

13. Ibrahim, N.; Tawfik, M. Egypt. J. Microbiol. 2019, 54, 117-135.

14. Meena, M.; Prasad, V.; Upadhyay, R. S. Bull. Environ. Sci. Res. 2016, 5, 1-7.

15. Charudattan, R.; Dinoor, A. Crop Prot. 2000, 19, 691-695.

16. Abdessemed, N.; Staropoli, A.; Zermane, N.; Vinale F. Pathogens. 2021, 10.

17. Ismaiel, A. A.; Papenbrock, J. Agriculture. 2015, 5, 492-537.

18. Radi, H.; Banaei-Moghaddam, A. Acta Scientific Microbiology. 2020, 3, 62-70.

19. Wang, H.; Guo, Y.; Luo, Z.; Gao, L.; Li, R.; Zhang, Y.; Kalaji, H. M.; Qiang, S.; Chen, S. J. Fungi. 2022, 8.

20. Lou, J.; Fu, L.; Peng, Y.; Zhou, L. Molecules. 2013, 18, 5891-935.

21. Howlett, B. J. Curr. Opin. Plant Biol. 2006, 9, 371-5.

22. Shi, J.; Zhang, M.; Gao, L.; Yang, Q.; Kalaji, H. M.; Qiang, S.; Strasser, R. J.; Chen, S. Cells. 2021, 10.

23. Davis, N. D.; Diener, U. L.; Morgan-Jones, G. Appl. Environ. Microbiol. 1977, 34, 155-7.

24. Sun, F.; Cao, X.; Yu, D.; Hu, D.; Yan, Z.; Fan, Y.; Wang, C.; Wu, A. Mol. Plant-Microbe Interact. 2022, 35, 416-427.

25. Rosett, T.; Sankhala, R. H.; Stickings, C. E.; Taylor, M. E.; Thomas, R. Biochem. J. 1957, 67, 390- 400.

26. Wan, Z.; Qiang, S.; Wu, Y. Journal of Beihua University (Natural Science). 2001, 2, 428-430.

27. Qiang, S.; Wang, L.; Wei, R.; Zhou, B.; Chen, S.; Zhu, Y.; Dong, Y.; An, C. Weed Technol. 2010, 24, 197-201.

28. Zhou, B.; Qiang, S. J. Agro-Environ. Sci. 2007, 26, 572–576.

29. Kang, Y.; Feng, H.; Zhang, J.; Chen, S.; Valverde, B. E.; Qiang S. Plant Physiol. Biochem. 2017, 115, 73-82.

30. Chen, S.; Qiang, S. Pestic. Biochem. Physiol. 2017, 143, 252-257.

31. Iwasaki, S.; Muro, H.; Nozoe, S.; Okuda, S.; Sato, Z. Tetrahedron Letters. 1972, 13, 13-16.

32. Steyn, P. S.; Rabie, C. J. Phytochemistry. 1976, 15, 1977-1979.

33. Nishimura, S.; Kohmoto, K. Annu. Rev. Phytopathol. 1983, 21, 87-116.

34. Ebbole, D. J. Annu. Rev. Phytopathol. 2007, 45, 437-456.

35. Zhou, B.; Wang, H.; Meng, B.; Wei, R.; Wang, L.; An, C.; Chen, S.; Yang, C.; Qiang, S. Pest Manage. Sci. 2019, 75, 2482-2489.

36. Templeton, G. E., in: Microbial Toxins, Vol. 6, S Kadis, A Ciegler, and SJ Ajil, Ed., Academic Press, New York/London, 1972, 169-192.

37. Meena, M.; Samal, S. Toxicol. Rep. 2019, 6, 745-758.

38. Chelkowski, J.; Visconti, A., Elsevier Science, Amsterdam, London, New York, Tokyo. 1992, 449- 541.

39. Zonno, M. C.; Vurro, M. Weed Research. 1999, 39, 15-20.

40. Janardhanan, K. K.; Husain, A. J. Phytopathol. 1984, 111, 305-311.

41. Apel, K.; Hirt, H. Annu. Rev. Plant Biol. 2004, 55, 373-399.

42. Laloi, C.; Apel, K.; Danon, A. Curr. Opin. Plant Biol. 2004, 7, 323-328.

43. Chen, S.; Yin, C.; Qiang, S.; Zhou, F.; Dai X. Biochim. Biophys. Acta. 2010, 1797, 391-405.

44. Gatenbeck, S.; Sierankiewicz, J. Antimicrob Agents Chemother. 1973, 3, 308-9.

45. Miller, F. A.; Rightsel, W. A.; Sloan, B. J.; Ehrlich, J.; French, J. C.; Bartz, Q. R.; Dixon, G. J. Nature. 1963, 200, 1338-1339.

46. Nukina, M.; Saito, T. Biosci., Biotechnol., Biochem. 1992, 56, 1314-1315.

47. Stickings, C. E. Biochem. J. 1959, 72, 332-40.

48. Stickings, C. E.; Townsend, R. J. Biochem. J. 1961, 78, 412-418.

49. Collemare, J.; Billard, A.; Böhnert, H. U.; Lebrun, M.-H. Mycol. Res. 2008, 112, 207-215.

50. Royles, B. J. L. Chemical Reviews. 1995, 95, 1981-2001.

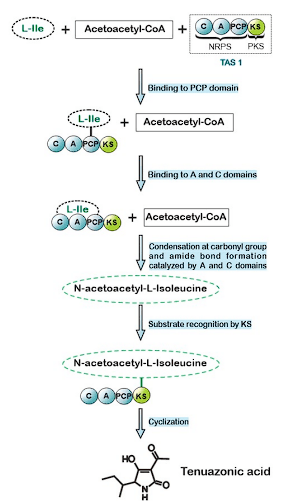

51. Yun, C.-S.; Motoyama, T.; Osada, H. Nat. Commun. 2015, 6, 8758.

52. Yun, C. S.; Nishimoto, K.; Motoyama, T.; Shimizu, T.; Hino, T.; Dohmae, N.; Nagano, S.; Osada, H. J. Biol. Chem. 2020, 295, 11602-11612.

53. Mo, X.; Gulder, T. A. M. Nat. Prod. Rep. 2021, 38, 1555-1566.

54. Chen, S.; Zhou, F.; Yin, C.; Strasser, R. J.; Yang, C.; Qiang, S. Environ. Exp. Bot. 2011, 73, 31-41.

55. Chen, S.; Yin, C.; Strasser, R. J.; Govindjee; Yang, C.; Qiang, S. Plant Physiol. Biochem. 2012, 52, 38-51.

56. Qin, J. C.; Zhang, Y. M.; Hu, L.; Ma, Y. T.; Gao, J. M. Nat. Prod. Commun. 2009, 4, 1473-6.

57. Lebrun, M. H.; Nicolas, L.; Boutar, M.; Gaudemer, F.; Ranomenjanahary, S.; Gaudemer, A. Phytochemistry. 1988, 27, 77-84.

58. Bok, J. W.; Keller, N. P. Eukaryot Cell. 2004, 3, 527-35.

59. Yun, C.-S.; Motoyama, T.; Osada, H. ACS Chem. Biol. 2017, 12, 2270-2274.

60. Pero, R. W.; Posner, H.; Blois, M.; Harvan, D.; Spalding, J. W. Environ. Health Perspect. 1973, 4, 87- 94.

61. EFSA. EFSA J. 2011, 9, 2407. DOI: https://doi.org/10.2903/j.efsa.2011.2407.

62. EFSA; Arcella, D.; Eskola, M.; Gómez Ruiz, J. A. EFSA J. 2016, 14, e04654. DOI: https://doi.org/10.2903/j.efsa.2016.4654.

63. Fehr, M.; Pahlke, G.; Fritz, J.; Christensen, M. O.; Boege, F.; Altemöller, M.; Podlech, J.; Marko, D. Mol. Nutr. Food Res. 2009, 53, 441-451.

64. Tiessen, C.; Fehr, M.; Schwarz, C.; Baechler, S.; Domnanich, K.; Böttler, U.; Pahlke, G.; Marko, D. Toxicol. Lett. 2013, 216, 23-30.

65. Aichinger, G.; Beisl, J.; Marko, D. Mol. Nutr. Food Res. 2017, 61, 1600462.

66. Fleck, S. C.; Burkhardt, B.; Pfeiffer, E.; Metzler, M. Toxicol. Lett. 2012, 214, 27-32.

67. Schwarz, C.; Tiessen, C.; Kreutzer, M.; Stark, T.; Hofmann, T.; Marko, D. Arch. Toxicol. 2012, 86, 1911-1925.

68. Tiessen, C.; Gehrke, H.; Kropat, C.; Schwarz, C.; Bächler, S.; Fehr, M.; Pahlke, G.; Marko, D. World Mycotoxin J. 2013, 6, 233-244.

69. Aichinger, G.; Del Favero, G.; Warth, B.; Marko, D. Compr. Rev. Food Sci. Food Saf. 2021, 20, 4390- 4406.

70. Roberts, J.; Florentine, S.; Fernando, W. G. D.; Tennakoon, K. U. Plants. 2022, 11, 2242.

71. https://www.dof.gob.mx/nota_detalle.php?codigo=5609365, accessed in February 2023

72. Dalinova, A. A.; Salimova, D. R.; Berestetskiy, A. O. Appl. Biochem. Microbiol. 2020, 56, 256-272.

73. Triolet, M.; Guillemin, J.-P.; Andre, O.; Steinberg, C. Weed Res. 2019, 60, 60-77.

74. Hasan, M.; Ahmad-Hamdani, M. S.; Rosli, A. M.; Hamdan, H. Plants. 2021, 10, 1212.

75. Hoagland, R. E.; Boyette, C. D. J. Fungi. 2021, 7, 1032.

76. Duke, S. O.; Pan, Z.; Bajsa-Hirschel, J.; Boyette, C. D. Adv. Weed Sci. 2022, 40.

77. Siddiqui, I.; Bajwa, R. Int. J. Agric. Biol. 2008, 10, 722-724.

78. Siddiqui, I.; Bajwa, R.; Javaid, D. A. Afr. J. Biotechnol. 2010, 9, 8308-8312.

79. Babu, R. M.; Sajeena, A.; Seetharaman, K. Crop Protection. 2003, 22, 1005-1013.

80. Dagno, K.; Lahlali, R.; Diourté, M.; Jijakli, M. H. Biotechnol., Agron., Soc. Environ. 2012, 16, 360- 368.

81. Singh, A. K.; Pandey, A. K. Int. J. Plant Environ. 2022, 8, 44-51.

82. Cordeau, S.; Triolet, M.; Wayman, S.; Steinberg, C.; Guillemin, J.-P. Crop Prot. 2016, 87, 44-49.

83. Kausar, T.; Jabeen, K.; Javaid, A.; Iqbal, S. Adv. Weed Sci. 2022, 40.

84. Sands, D. C.; Pilgeram, A. L. Pest. Manag. Sci. 2009, 65, 581-587.

85. Suckling, D. M. Biol. Control. 2013, 66, 27-32.

.jpg&w=3840&q=75)