Beneficial Fungus Formulated into Bioplastic "Bullets"

Published: October 5, 2012

By: Jan Suszkiw, USDA-ARS

Aflatoxins are highly toxic substances produced by several species of Aspergillus fungi. But not all Aspergillus produce aflatoxins. Some, in fact, are considered beneficial. One such strain, K49, is now being recruited to battle its harmful Aspergillus relatives, preventing them from contaminating host crops, like corn, with the carcinogen.

In collaboration with Italy's University of Bologna (UB) microbiologist Cesare Accinelli, ARS plant pathologist Hamed Abbas and ARS soil microbiologist Bob Zablotowicz (now retired) devised a new method of formulating K49 as a first-line defense against aflatoxin contamination of corn, which costs an estimated $200 million annually in U.S. losses alone. So potent is the aflatoxin that U.S. law prohibits the sale of corn or any grain destined for human consumption if it contains more than 20 parts per billion.

K49 is known as nontoxigenic (or atoxigenic) because of its inability to produce aflatoxin, explains Abbas, who is with ARS's Biological Control of Pests Research Unit in Stoneville, Mississippi. But the fungus, or mold, is quite adept at excluding its toxin-producing cousins (A. flavus and A. parasiticus) from ecological niches and resources that both need to survive. Exploiting this rivalry, called "biocompetitive exclusion," offers an effective way to diminish aflatoxin levels in both soil and corn kernels, says Abbas, who coauthored a 2011 Crop Protection paper with Accinelli and his colleagues at UB's Department of Agro-Environmental Science and Technology in Bologna, Italy.

Wheat and barley grains are typically used as carriers to apply commercial strains of biocompetitive Aspergillus molds. But instead of using those grains, the ARS-UB team encapsulated K49 in a bioplastic product, called "Mater-Bi," made of cornstarch, vegetable oil, and other constituents.

Plant pathologist Hamed Abbas applies the nontoxigenic Aspergillus flavus formulated in bioplastic granules to knee-high corn.

These bullet-shaped granules in which K49 is encapsulated offer several advantages, says Abbas. Chief among these is improved storage life and viability of the mold, once applied. The formulation's starch component also provides nourishment to the mold. And because actual wheat and barley grains aren't used, seed-hungry animals like rats and birds aren't likely to eat the formulation, giving K49 a chance to release spores for dispersal to corn plants via wind or insect feeding. The bioplastic is also a readily available resource that biopesticide makers can use, and it safely degrades in the environment, Abbas notes.

Following application, some of the nontoxigenic A. flavus bioplastic granules end up between the leaves of the developing corn plant. Most of the granules fall to the ground.

Hamed Abbas and technician Caleb Chambers prepare bioplastic granules for field trials to control aflatoxin in corn.

During field tests in the Mississippi Delta from 2001 to 2004, inoculation of grains with K49 dramatically reduced aflatoxin levels in corn (see "Protecting Corn From Aflatoxin," Agricultural Research, September 2010, pp. 8-10). In the latest round of trials, conducted by Accinelli's group near Bologna from 2009 to 2010, bioplastic formulations of K49 netted similar aflatoxin reductions (65 to 97 percent, depending on where applied).

"We find you get better results from applying K49 when corn is knee-high—or at what's called the '8-10 leaf stage'—than when it's at the tassling or silking stage," says Abbas.

A patent has been filed on the bioplastic formulation, and the researchers hope that its issuance will encourage a biopesticide manufacturer to license the technology and develop it commercially.

Meanwhile, they're comparing different granule sizes to determine which works best with airplane-mounted sprayers, which may make applying K49 more practical for growers. They're also evaluating mixtures of K49 and certain chemical pesticides, as well as other biocompetitive strains, for possible synergistic effects that could improve performance or save on field application costs. In addition, the unique bioplastic matrix may also be effective in delivering other soil-applied fungi for controlling crop diseases. For example, the bioplastic has been shown to be an attractive method of incorporating beneficial Trichoderma fungi into potting mix to protect flowers such as impatiens from fungi that cause damping-off disease.

"There's really no one good way of controlling aflatoxins by traditional means—certainly not with chemical fungicides," says Abbas. But combined with resistant cultivars and other measures, a new biocompetitive strain could give corn farmers an added tool to use in fortifying crops against outbreaks that can lead to contamination and costly losses. - By Jan Suszkiw, ARS.

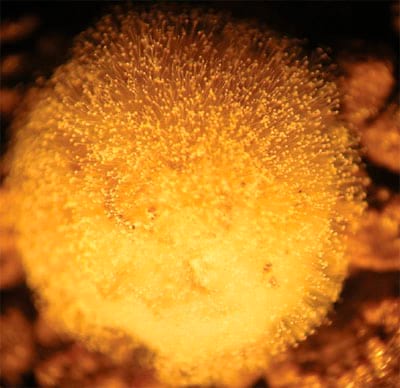

After a bioplastic granule is applied to the soil, the nontoxigenic A. flavus fungus grows and sporulates as shown.

This research is part of Plant Diseases, an ARS national program (#303) described at www.nps.ars.usda.gov.

Hamed K. Abbas is in the USDA-ARS Biological Control of Pests Research Unit, National Biological Control Laboratory, 59 Lee Rd., P.O. Box 67, Stoneville, MS 38776; (662) 686-5313, hamed.abbas@ars.usda.gov.*

Acknowledgement

This article was originally published in the U.S Department of Agriculture´s science magazine, Agricultural Research, October 2012. Engormix.com thanks for this huge contribution.

Source

Jan Suszkiw, USDA-ARSRelated topics:

Recommend

Comment

Share

Would you like to discuss another topic? Create a new post to engage with experts in the community.