Intelscan provides a tool to effectively control feed moisture

Published: June 11, 2009

Source : Engormix.com

United Pet Food in Belgium optimises the product quality and production efficiency by using Intelscan on-line moisture sensor system. UNITED PETFOOD NV is located at the harbour of Ghent, Belgium. Since 1997, the company has specialized in the production of extruded dry pet food.

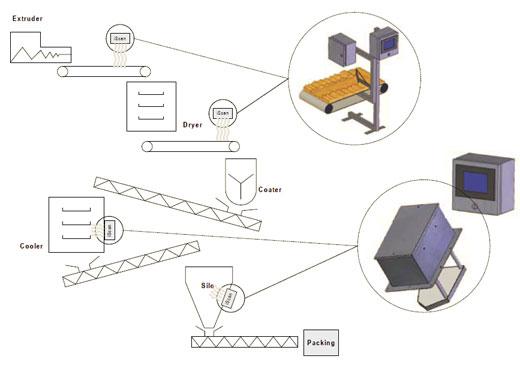

Less re-work and a more uniform moisture content of the product “In our production line, the Intelscan sensor is installed after the Geelen dryer, and is performing exceptionally well” explains Mr. Patrick Fernagut, factory manager at United Petfood.

“Before we installed the sensor we sometimes received complaints that our petfood contained too much water. We therefore often needed to re-process some of our product. It was obvious that we needed a better tool to control our drying process. With the Intelscan equipment we were able to identify the section of the drying process that needed to be improved in order to secure a more uniform moisture content of the product.”

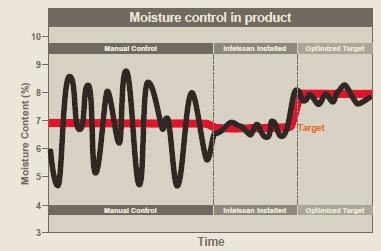

With on-line moisture measurement, fluctuations of moisture are reduced. The Intelscan sensor is installed either before and/or after a dryer and/or inside the cooler.

Main Benefits

Quality; Better control of feed moisture increases shelf-life.

Profitability; Optimise end product quality and production efficiency.

Savings; Prevent over-drying, which saves energy.

Labour saving; No need for taking samples every 30 minutes.

Reduces risks; Detect abnormalities directly.

Optimises drying process; Real-time updated information about the moisture level is sent directly to the

dryer control system. Fluctuations in moisture are reduced.

Traceability; Moisture measurement data is stored in the factory control system.

Calibration; With many products, only one calibration is needed.

System Overview

The sensor can be installed at various locations in the production process. It provides an accurate overview of real time values of moisture, density and temperature during different stages of processing. The system is suitable for all feeds and is neither affected by colour or shape of the product, nor a dusty or humid environment.

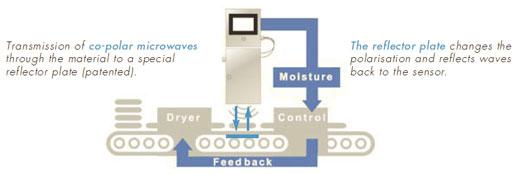

Technological Principle

The attenuation and phase change of the signal that has travelled twice through the material is measured. The effects from reflections of surrounding surfaces is minimized by confining the area of measurement. Based on this measurement principle, only one calibration is needed for many types of recipies, colours, sizes and density.

Specifications

Measurement

Measuring range 0-90% moisture content

Measurement update 1 - 30 seconds (adjustable)

Accuracy of moisture measurement +/- 0.5% (or better) compared to standard dry oven reference

Density accuracy +/- 15g/l

Calibration Up to 20 different calibration settings can be stored

Network Ethernet connectivity

Measurement output Industry standard 4-20mA and 0-5V outputs for moisture, temperature or density

Digital IO Multiple in- and outputs

Data storage Locally with a Removable Flash Disk, anywhere remotely via network connection

Tested to safety standard IEC 61010-1

Measuring range 0-90% moisture content

Measurement update 1 - 30 seconds (adjustable)

Accuracy of moisture measurement +/- 0.5% (or better) compared to standard dry oven reference

Density accuracy +/- 15g/l

Calibration Up to 20 different calibration settings can be stored

Network Ethernet connectivity

Measurement output Industry standard 4-20mA and 0-5V outputs for moisture, temperature or density

Digital IO Multiple in- and outputs

Data storage Locally with a Removable Flash Disk, anywhere remotely via network connection

Tested to safety standard IEC 61010-1

Power Consumption

Sensor unit <7W

Display unit <12W

Sensor unit <7W

Display unit <12W

Electrical

Power 110-240V, single phase 2A supply

Frequency

Microwave frequency 2 GHz - 12 GHz (depending on application)

Microwave field strength At 8 GHz: <0.056V/m

Microwave frequency 2 GHz - 12 GHz (depending on application)

Microwave field strength At 8 GHz: <0.056V/m

Enviroment

Operating temperature 0 - 55°C

Weight and dimensions

Weight 12 kg

Sensor unit 240x240x150mm(online)/200x270x180mm(silo) (H x W x D)

Display unit 240x240x150mm (H x W x D)

Stainless steel IP65 enclosure

Source

Engormix.comRelated topics:

Recommend

Comment

Share

Would you like to discuss another topic? Create a new post to engage with experts in the community.