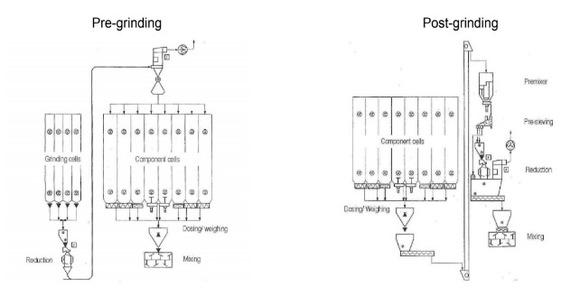

Pre-milling and post-milling systems

Among the various stages of the pelleting process, grinding is one of those that consume more energy, but it’s essential for pelletizing because it allows to create a homogeneous mixing and to reduce the volumes. In fact, in the compound-feed production process 60% of the total energy consumption is used for pelleting, 16% for milling, 14% for conveying, 7% for receiving, 2% for mixing and 1% for delivery. Particle size reduction is the first step in the feed manufacturing process and, in terms of pellet mill operations, has a great influence on pellet quality (between 15% and 20%). Grinding, or particle-size reduction, is a major function of pellet manufacturing for several reasons, all of them improving the ease of handling ingredients and their storability: - clumps and large fragments are reduced in size; - some moisture is removed due to aeration; - additives such as antioxidants may be blended.

Mia Eeckhout ,

Thank u for your valuable discussion. I agree to post grinding is better than pregrinding due to short period of smaller surface area particles after grinding. I have 2 questions -

1. What is the optimum particle size after grinding (in case of broiler, cattle, and fish feed production)?

2. What size (MM hole) of screen is preferable for 2.5mm die?

Thanks.

Md. Sharif Uddin Biswas

Head of production

Way Agro Industry Pvt ltd

Dhaka,

Bangladesh

I am from BANGLADESH our weather is high humidity & tropical. In our experience, we found that pre milling is not suitable in our country weather, Because after milling product can not store long hours in dosing bins, it absorb moisture, going to mould/ bonding/cake tendencies. If storage bins use plain wall and vertically high then raw materials self load will create more problem. Bin size, design, specially reducing conical part incentric outlet is factor for easy flow. Some are using agitator with extra power, some are using oposite air blowing.

In my conclusion easy flow we are making poor flow when we will use pre grinding...

Regards, Altaf Hossain

Friends:

The question here is not which grinding step is better than the other one, the question is WHERE and WHEN to apply each of those during the feed processing.

It is well known that fine grinding provide more surface area of contact at the conditioning process compared against normal/coarse grinding, fine particles allow for the steam to penetrate into the piece faster than coarse particles and at the same time promotes a better starch gelatinization (hydrolization) and

better homogenization of the mash inside the conditioner. However, not all the operations use fine grinding all the time due to several reasons like high energy consumption and fast reduction of life in wear parts inside the hammermill.

When pelleting animal feeds we normally use a regular grinding step ahead of the dosage and mixing of the ingredients, this is called PRE-GRINDING. This process suggests a grinding degree equivalent to 600-700 microns geometrical particle size of the majority of the ingredients. Is very uncommon to see further grinding steps on a pellet mill operation except when we produce sinking shrimp feeds. However, this one is nowadays being produced by using extruders due to several benefits that I will happy to explain on another forum.

When we extrude animal feeds such as pet food, fish feed (sinking or floating) and shrimp feed we include the normal PRE-GRINDING step as usual but after mixing of the ingredients we grind the mash all together in a well-configured hammermill in order to achieve geometrical particle sizes equivalent to 180-200 microns (on aquafeeds) and/or 250-300 microns (on pet food).

Post-grinding hammermills utilize double grinding chamber with special impact plates along with a specific hammer pattern to achieve the grinding exigencies. Air assist system (negative or positive) is also required to help to relieve the internal pressure generated inside the mill when we grind very fine particles and also helps to avoid screens blinding during this process. A hammermill used as a post-grinder uses almost twice the horsepower per ton when compared against with pre-grinder hammermills. In addition, particles at 180-200 microns allow a better extrusion and better shapes production at the extruder die plate.

If anyone has further questions, please do not hesitate to reach me out and I will be glad to address any concerns.

Thank you.

Enrique Diaz.

North American Renderers Association (NARA)

Thank you all for your interest in this topic. I am pleased to see that there are many professionals in the Animal Feed industry who are happy to share their experiences and knowledge with others.

Based on the experience of La Meccanica, I agree with Mr. Enrique Diaz when he says that the question is not whether pre-milling is better than post-milling or vice versa. The question is where and when to apply each of these steps when processing the feed. Furthermore, great importance lies in the materials being processed and other factors (humidity and temperature).

Sandeep kumar , our technicians say that a reduction in the air flow rate leads to:

• a reduction in mill capacity

• finer product

• higher specific energy consumption

• greater heating during milling

• greater wear

• greater dust formation.

With screen holes diameter lower than 3 mm is not possible to work without aspiration because the risk of clogging is too high.