Heat damage, Maillard reactions, and measurement of reactive lysine in feed ingredients and diets

Almeida, F. N., J. K. Htoo, J. Thomson, and H. H. Stein. 2013. Amino acid digestibility of heat damaged distillers dried grains with solubles fed to pigs. J. Anim. Sci. Biotechnol. 4:44-44. doi 10.1186/2049-1891-4-44

Almeida, F. N., J. K. Htoo, J. Thomson, and H. H. Stein. 2014a. Digestibility by growing pigs of amino acids in heat-damaged sunflower meal and cottonseed meal. J. Anim. Sci. 92:585-

593. doi 10.2527/jas.2013-6769

Almeida, F. N., J. K. Htoo, J. Thomson, and H. H. Stein. 2014b. Effects of heat treatment on the apparent and standardized ileal digestibility of amino acids in canola meal fed to growing pigs. Anim. Feed Sci. Technol. 187:44-52. doi 10.1016/j.anifeedsci.2013.09.009

Almeida, F. N., J. K. Htoo, J. Thomson, and H. H. Stein. 2014c. Effects of balancing crystalline amino acids in diets containing heat-damaged soybean meal or distillers dried grains with solubles fed to weanling pigs. Animal 8:1594-1602. doi 10.1017/S175173111400144X

Bothast, R. J., and M. A. Schlicher. 2005. Biotechnological processes for conversion of corn into ethanol. Appl. Microbiol. Biotechnol. 67:19-25. doi 10.1007/s00253-004-1819-8

Bujard, É., P. A. Finot, R. Madelaine, A. Lê van Kiet, R. Deutch, and A. Isely. 1978. Mesure de la disponibilité et du blocage de la lysine dans les laits industriels. Ann. Nutr. Alim. 32:291-

305.

Couch, J. R., and M. C. Thomas. 1976. A comparison of chemical methods for the determination of available lysine in various proteins. J. Agric. Food Chem. 24:943-946. doi

10.1021/jf60207a033

Cozannet, P., Y. Primot, C. Gady, J. P. Métayer, P. Callu, M. Lessire, F. Skiba, and J. Noblet.

2010. Ileal digestibility of amino acids in wheat distillers dried grains with solubles for pigs.

Anim. Feed Sci. Technol. 158:177-186. doi 10.1016/j.anifeedsci.2010.04.009

Chung, S. Y., S. H. Han, S. W. Lee, and C. Rhee. 2012. Effect of Maillard reaction products prepared from glucose–glycine model systems on starch digestibility. Starch - Stärke

64:657-664. doi https://doi.org/10.1002/star.201100176

Dworschák, E. 1980. Nonenzyme browning and its effect on protein nutrition. Crit. Rev. Food

Sci. Nutr. 13:1-40. doi 10.1080/10408398009527292

Eklund, M., N. Sauer, F. Schöne, U. Messerschmidt, P. Rosenfelder, J. K. Htoo, and R.

Mosenthin. 2015. Effect of processing of rapeseed under defined conditions in a pilot plant on chemical composition and standardized ileal amino acid digestibility in rapeseed meal for pigs. J. Anim. Sci. 93:2813-2825. doi 10.2527/jas.2014-8210

Finot, P., and E. Magnenat. 1981. Metabolic transit of early and advanced Maillard products.

Prog. Food Nutr. Sci. 5:193-207.

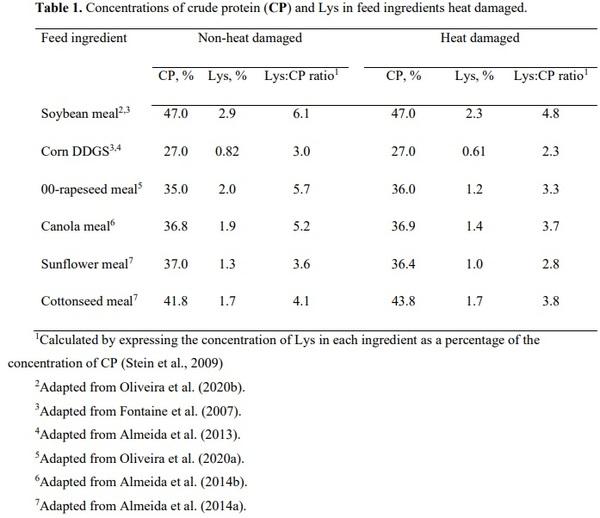

Fontaine, J., U. Zimmer, P. J. Moughan, and S. M. Rutherfurd. 2007. Effect of heat damage in an autoclave on the reactive lysine contents of soy products and corn distillers dried grains with solubles. Use of the results to check on lysine damage in common qualities of these ingredients. J. Agric. Food Chem. 55:10737-10743. doi 10.1021/jf071747c

Gerrard, J. A. 2002. New aspects of an ageing chemistry - recent developments concerning the

Maillard reaction. Aust. J. Chem. 55:299-310. doi 10.1071/CH02076

Goebel, K. P., and H. Stein. 2011. Ileal digestibility of amino acids in conventional and lowkunitz soybean products fed to weanling pigs. Asian-Australas J. Anim. Sci. 24. doi

10.5713/ajas.2011.90583

González-Vega, J. C., B. G. Kim, J. K. Htoo, A. Lemme, and H. H. Stein. 2011. Amino acid digestibility in heated soybean meal fed to growing pigs. J. Anim. Sci. 89:3617-3625. doi

10.2527/jas.2010-3465

Hirano, F., H. Kato, and M. Fujimaki. 1973. Racemization of amino acid residues in proteins during roasting. Agric. Biol. Chem. 37:191-192. doi 10.1080/00021369.1973.10860651

Hodge, J. E. 1953. Dehydrated foods, chemistry of browning reactions in model systems. J.

Agric. Food Chem. 1:928-943. doi 10.1021/jf60015a004

Kerr, B. J., T. A. Kellner, and G. C. Shurson. 2015. Characteristics of lipids and their feeding value in swine diets. J. Anim. Sci. Biotechnol. 6:30. doi:10.1186/s40104-015-0028-x

Kim, B. G., D. Y. Kil, Y. Zhang, and H. H. Stein. 2012. Concentrations of analyzed or reactive lysine, but not crude protein, may predict the concentration of digestible lysine in distillers dried grains with solubles fed to pigs. J. Anim. Sci. 90:3798-3808. doi 10.2527/jas.2011-

4692

Kimmel, J. R. 1967. Guanidination of proteins. Pages 584-589 in Methods in Enzymology

Academic Press.

Langner, E., and W. Rzeski. 2014. Biological properties of melanoidins: A review. Int. J. Food

Prop. 17:344-353. doi 10.1080/10942912.2011.631253

Liener, I. E. 1994. Implications of antinutritional components in soybean foods. Crit. Rev. Food

Sci. Nutr. 34:31-67. doi 10.1080/10408399409527649

Meade, S. J., E. A. Reid, and J. A. Gerrard. 2005. The impact of processing on the nutritional quality of food proteins. J. AOAC. Int. 88:904-922.

Mehta, B. M., and H. C. Deeth. 2016. Blocked lysine in dairy products: Formation, occurrence, analysis, and nutritional implications. Compr. Rev. Food Sci. Food Saf. 15:206-218. doi

10.1111/1541-4337.12178

Moughan, P. J. 2003. Amino acid availability: Aspects of chemical analysis and bioassay methodology. Nutr. Res. Rev. 16:127-141. doi 10.1079/NRR200365

Nursten, H. 2005. The Maillard Reaction. Chemistry, Biochemistry, and Implications. Royal

Society of Chemistry, Cambridge, UK.

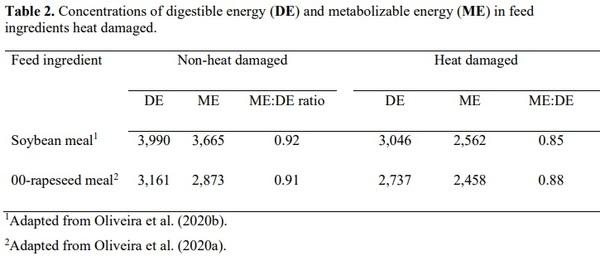

Oliveira, M. S. F., M. K. Wiltafsky-Martin, and H. H. Stein. 2020a. Excessive heating of 00- rapeseed meal reduces not only amino acid digestibility but also metabolizable energy when fed to growing pigs. J. Anim. Sci. 98. doi 10.1093/jas/skaa219

Oliveira, M. S. F., M. K. Wiltafsky, S. A. Lee, W. B. Kwon, and H. H. Stein. 2020b.

Concentrations of digestible and metabolizable energy and amino acid digestibility by growing pigs may be reduced by autoclaving soybean meal. Anim. Feed Sci. Technol.

269:114621. doi https://doi.org/10.1016/j.anifeedsci.2020.114621

Pahm, A. A., C. Pedersen, and H. H. Stein. 2008. Application of the reactive lysine procedure to estimate lysine digestibility in distillers dried grains with solubles fed to growing pigs. J.

Agric. Food Chem. 56:9441-9446. doi 10.1021/jf801618g

Pahm, A. A., C. Pedersen, and H. H. Stein. 2009. Standardized ileal digestibility of reactive lysine in distillers dried grains with solubles fed to growing pigs. J. Agric. Food Chem.

57:535-539. doi 10.1021/jf802047d

Patience, J. F., M. C. Rossoni-Serão, and N. A. Gutiérrez. 2015. A review of feed efficiency in swine: Biology and application. J. Anim. Sci. Biotechnol. 6. doi 10.1186/s40104-015-0031-

2

Ramírez-Jiménez, A., B. García-Villanova, and E. Guerra-Hernández. 2001. Effect of toasting time on the browning of sliced bread. J. Sci. Food Agric. 81:513-518. doi 10.1002/jsfa.840

Rehman, Z., and W. H. Shah. 2005. Thermal heat processing effects on antinutrients, protein and starch digestibility of food legumes. Food Chem. 91:327-331. doi

10.1016/j.foodchem.2004.06.019

Rutherfurd, S. M., and G. S. Gilani. 2009. Amino acid analysis. Curr. Protoc. Protein Sci.

58:11.19.11-11.19.37. doi 10.1002/0471140864.ps1109s58

Stein, H. H., S. P. Connot, and C. Pedersen. 2009. Energy and nutrient digestibility in four sources of distillers dried grains with solubles produced from corn grown within a narrow geographical area and fed to growing pigs. Asian-Australas J. Anim. Sci. 22:1016-1025. doi

10.5713/ajas.2009.80484

Zhang, Q., J. M. Ames, R. D. Smith, J. W. Baynes, and T. O. Metz. 2009. A perspective on the

Maillard reaction and the analysis of protein glycation by mass spectrometry: Probing the pathogenesis of chronic disease. J. Proteome Res. 8:754-769. doi 10.1021/pr800858h