European finfish culture

European finfish culture: current status, recent advances and future perspectives

The latest review of the state of world aquaculture from the Fisheries and Agriculture Organization (FAO) 2003 and the latest FAO Fishstat Plus statistics from 1950-2001 highlight the continuing growth of aquaculture in contributing to the total fisheries catch (Figure 1).

Aquaculture represented 5.3% of the total fisheries landings in 1970 and this had increased to 34% in 2001, i.e. 48.4 million metric tonnes (mmt) of the total fisheries landings of 142.1 mmt. The value of world aquaculture production is now estimated at 61.5 billion US$. Globally the sector has shown an average annual compounded growth rate (APR) of 8.9% since 1970 compared to 1.4% for capture fisheries and 2.8% for terrestrial farmed meat production.

Figure 1. World fisheries and aquaculture production (FAO, 2003).

Finfish production at 24.4 mmt represents 50% of the aquaculture production and over 130 major finfish species are cultured world-wide. These statistics alone emphasize the scale, complexity, rate of development and diversification of the global finfish aquaculture sector.

European aquaculture

Europe has a total aquaculture production of over 2 mmt, and of the 210 aquaculture species cultured worldwide 60 are cultured in Europe with a value of 4.6 billion US$. This means that while Europe contributes 4.4% to global production, it represents 8.2% of its total value. Recently growth from aquaculture has slowed from 7.8% p.a. in the period 1980 to 1990 to 2.3% p.a. in the period 1990 to 2000.

In 2001, 1.34 mmt of Europe’s 2 mmt was attributed to finfish production and the breakdown of production among fresh, brackish and marine environments is shown in Figure 2. Salmon, trout, sea bass and sea bream account for over 1 mmt or 3 billion US$ in value. Salmon is by far the largest activity accounting for 647 thousand metric tonnes (tmt) and 1.86 billion US$. The marine and diadromous finfish species are valued at nearly 3 times the price of the fresh water species according to global FAO statistics and it is primarily in this area that European aquaculture has focused and developed (Tacon, 2003).

Table 1 shows the breakdown of the finfish species cultured in Europe and it can be seen that the largest growth is in mariculture with salmon, sea bream, sea bass and turbot. Currently the 15 countries of the European Union produce approximately 50% of the finfish total but that proportion will change with the accession of a further 10 countries later this year.

Figure 2. European finfish production by environment (1996-2001).

Table 1. European finfish production by species (1996-2001) in metric tonnes1.

1FAO/FEAP, 2003.

SALMON PRICE: A CONTROLLING FACTOR

Salmon prices have decreased since 2000; and in 2003 reached their lowest point ever at under 2 €/kg, with a recent average price of approximately 2.5 €/kg (Figure 3). This for many farms is at or below their production costs. Due to the importance of this species in the overall framework of the European industry, the repercussions for industry as a whole have been significant. During the same period price decreases were also being seen in the sea bass and sea bream industry with similar effects. Overall in the EU there has been a 6.5% APR in production growth but the overall price trend has been negative (-0.5% APR) versus a positive global development (FEAP). Share prices have fallen sharply, particularly in the salmon industry; and investment confidence in aquaculture has been shaken. Pressure has been placed on the industry to further improve efficiency and productivity. Acquisitions and mergers have been the order of the day and groups are consolidating in order to benefit financially.

Significantly, with salmon being the power house of the European industry, diversification into other marine finfish species has been slowed due to the reluctance of financial institutions to invest in a variant of this troubled sector. Further, this financial pressure comes at a time when consumer awareness is focusing upon product quality, ease of product use, food safety, and traceability. This is also occurring during a period when the image of aquaculture has suffered by what the industry feels is often unfair treatment in the press.

Figure 3. Cross section price for fresh whole gutted superior Atlantic Salmon, iced in poly boxes (Intrafish).

The industry, while weakened, has responded with a positive approach. At every level the aquaculture sector is promoting transparency, cooperation and dialogue. The Federation of European Aquaculture Producers (FEAP) initiated the ‘Aquamedia’ project and this is now providing factual, truthful and interesting information about European aquaculture to the public.

In order to focus the European effort and to promote a coherent development strategy, FEAP reported to a hearing on European Aquaculture held by the EU committee of the European Parliament in October 2002. The following key issues were presented:

- Improved economic viability, long term market stability and improved profit margins within the industry are essential in order to stimulate investment and reinvestment.

- Improved access to consolidated marketing and promotional efforts would benefit the medium and smaller producers.

- The industry should within the EU operate on an even playing field with regard to imported products.

- Food safety should be a guarantee for the consumer.

- Ingredient input quality to be provided by the feed manufacturers.

- The practical application of traceability and labeling to be implemented.

- The industry should be sustainable with regard to environmental impact and resource issues e.g. water/feed/biodiversity.

- Ensure human resources continuation through training, technology and professional entry.

- Better governance and responsibility within the industry.

- Better acceptance of aquaculture by the public.

It concluded that the long-term viability of the sector would depend upon the satisfaction of these multiple criteria and that the development of sustainable and responsible aquaculture will require coherent and viable European actions including simplified legislation and simplified licensing procedures.

Evolution of European finfish culture

The marine and diadromus finfish sector is of vital importance to the European industry and consists primarily of high valued species requiring considerable technological and managerial sophistication to culture in a sustainable manner. The critical developments that were responsible for the commercialization of these species and their subsequent diversification are outlined below. Further areas of future development and improvement required to ensure the continued development of the industry are considered in light of the rapidly evolving requirements of modern day Europe and the consumer.

While the latest FAO/FEAP statistics described above provide a fascinating insight to the development of the aquaculture industry, they obviously lack the benefit of real time information and the regional focus of development promoted by the European Union, national governments and the industrial sector. This has been achieved through supporting research and development, financial support for the establishment of the industry and by addressing marketing and consumer needs. These driving forces have provided a basis for development and diversification.

CRITERIA FOR SPECIES SELECTION

The selection of a species suitable for European aquaculture depends primarily on its market value, an understanding of its biology and the ability to produce juveniles in significant numbers for commercial production to take place. Given these characteristics and suitable site availability with the correct environmental conditions for culture, the evolution to maturity of a specific species industry can be summarized in the following stages:

- Identification and selection of high value species together with the R&D necessary to provide an understanding of the species biology and nutrition.

- The development of reproductive technologies to close the life cycle of the species considered together with the acquisition, domestication and manipulation of broodstock to produce eggs year round.

- The industrialization of technologies required for the commercial production of juveniles and their ongrowing.

- Improvement in productivity through economies of scale and the reduction of costs through vertical integration.

- Improvement in productivity through biotechnological solutions such as genetic advancement and nutritional engineering.

- Increased market activity through commercial pressure with the development of quality labeling, processing and other value added activities.

- Streamlining of the industry due to increased production, reduced profits resulting in grouping, mergers and consolidation to remain commercially competitive.

- The maturation of the industry and the species losing its status of a high value item and becoming a commodity product.

- Species diversification in search of additional profits through a recycling of the above procedure.

TRANSFER OF TECHNOLOGY BETWEEN SPECIES

The transition from salmon to other marine species is of particular interest and importance as it involved the transfer of on-growing technologies from Norway and Scotland to the Mediterranean for the sea bass and sea bream industries in the 1980s to 1990s. This, however, in itself was not sufficient as the reproductive technologies, zootechnical, nutritional and environmental conditions required for the culture of marine finfish juveniles were significantly different from those of salmon.

A swim up salmon fry (150 mg wet weight) is many times larger in body mass than that of a sea bream (0.35 mg wet weight), and while the salmon fry is capable at first feeding of ingesting and digesting inert particulate feeds this is not the case for many marine species. Due to the rather underdeveloped digestive system of these larvae and their behaviour, a sophisticated live food chain was required. Researchers and industry concentrated efforts to develop a species-specific nutritional strategy and to identify the correct environmental conditions enabling these very small and sensitive larvae to be successfully reared and develop sufficiently to be weaned onto inert diets before traditional on-growing technologies could then be used.

Since the 1980s, larval rearing technologies have been continually developing for the sea bass, sea bream and turbot industries and today they are well understood. Survival rates for these species have increased from less than 1% to between 20 and 40% in 10 years. In the last few years these warm water larval rearing technologies have been adapted and introduced to Norway and Scotland, enabling the mass production of a marine cold water species, the cod (Gadus morhua). While production of cod is expected to reach only 12,000 tonnes in 2005, this species, which occupies the same environmental conditions as salmon, offers an alternative or addition to the troubled salmon industry.

Economically, the present viability of these two species in the UK can be summarized as shown in Table 2 (R. Prickett, personal communication); and it should be noted that as technology and food conversion rates improve for cod, so should profits. History indicates however that as volume increases so market prices will reduce.

It is developments such as these that offer Europe the potential to continue expanding and diversifying its existing aquaculture industry by looking forward to new and more profitable species through the adaptation and development of existing biotechnologies and management strategies.

Table 2. Comparative profitability of salmon and cod in the UK in 2003.

| Salmon | Cod | |

| Cost per kg (round) | €2.04 | €2.82 |

| Cost of harvesting/gutting etc | €0.423 | €0.423 |

| Yield (head on gutted) | 90% | 86% |

| Cost per kg (head on gutted) | €2.735 | €3.765 |

| Market price (head on gutted) | €2.735 | €4.935 |

| Profit/kg 0 | €1.170 | (31%) |

| Cost of filleting | €0.141 | €0.141 |

| Yield after filleting (head on gutted) | 68% | 55% |

| Cost/kg (fillet/skin on) | €4.23 | €9.23 |

Reproductive technologies

It has been estimated that less than 3% of the total world aquaculture production is based on genetically improved stocks. Norway started to work on the selection of salmon in the 1960s and it was found that there was a large genetic variability for important production traits between wild and culture stocks offering potential for improvement. The best strains were then used as a base population for a national genetic improvement programme. This has lead to the development of salmon strains that show a genetic gain of around 100% for growth rate as well as other important characteristics such as late maturing individuals, resulting in improved production characteristics and reduced production costs. A similar breeding programme carried out using tilapia in the Philippines has shown more than a 100% improvement in growth rate over 10 generations.

In both species, selection for high growth rate can result in a gain of over 10% per generation. Only in the last 10 years has European Union research focused on broodstock genetics and selection programmes for the sea bass and sea bream industry in the Mediterranean. Prior to this production was still based on wild broodstock and selection from F1 cage production, with little monitoring to avoid inbreeding.

Traditionally, preventing inbreeding has been the largest problem in fish breeding programmes, due to large full sibling groups and the lack of individual identification methods. Today the identification of individual broodstock fish using microchip tagging is commonplace. The cost of microsatelite DNA and AFLPs (amplified fragment length polymorphisms) labelling has significantly decreased enabling the tracking of pedigrees and providing linkage maps to identify quantitative trait loci, such as growth and disease resistance, that have commercial importance (Agresti et al., 2000). These technologies have enabled individual producers to carry out selection methods and apply them in a practical manner in the industrial environment.

Growth rate is generally the first characteristic of importance for fish farmers as it is relatively easy to select and quantify. Other traits thought to be genetically dependent, for example disease resistance and flesh quality (muscular lipid content, fat deposition), are difficult to measure and require a more complex approach often beyond the abilities of the individual farmer. Various thematic R&D programmes within the European Union are now addressing many of these issues.

Many species still prove difficult to spawn in captivity, particularly in intensive production systems, an example being sole (Solea senigalensis). Triggers for male and female maturation and ovulation are still not well understood for this and other species such as the groupers and some tuna species. Endocrine regulation of reproduction has been effectively applied in some species and hormonal implants are readily available (Zohar and Mylonas, 2001). More investigation of the environmental and nutritional requirements of many species is required as the production of viable eggs is a prerequisite to the culture of any species.

Egg quality has a significant impact on the viability, survival and growth of marine larvae. The enrichment of broodstock diets with essential fatty acids and other vitamins and minerals have been shown to relate directly with the levels of these substances in marine eggs and larvae (Watanabe, 1993; Cedra et al., 1994; Harel et al., 1994).

Marine larval rearing technologies

The very small and sensitive larvae require the establishment of a reliable chain of live food production consisting of unicellular marine algae, the rotifer Branchionus plicatilis and the brine shrimp Artemia salina. This is common to both the cold water species, namely cod and halibut, and the warm water species such as sea bass, sea breams, turbot and sole. The most commonly cultured algal species in Europe belong to the five taxonomic groups (Table 3) and the choice of species depends on the fish species being cultured.

Table 3. Commonly cultured unicellular planktonic algae.

| Bacillariophycaea (Diatoms) | Chaetoceros calcitrans Skeletonema costatum |

| Chlorophycaeae – green algae | Dunaliella tertiolecta Chlorella spp. Nannochloris atomus |

| Chrysophyceae | Tetraselmis suecica Tetraselmis chuii |

| Eustigmatophyceae | Nannochloropsis oculata Nannochloropsis gaditana |

| Haptophyceae | Isochrysis galbana Isochrysis spp. (Tahititan strain) Pavlova lutheri |

The use of algae in the larval rearing tanks, the ‘green water technique’, is not limited to the purely nutritional side of rotifer enrichment but has other practical applications:

- Algae can act as an antibacterial agent (Austin and Day, 1990; Cooper et al., 1983). In addition, specific polysaccharides in the algae cell wall are thought to stimulate a non-specific immune response in young larvae.

- Algae have been reported to act as an in situ biological filter removing potentially harmful metabolites from the water by stripping off nitrogenous substances. They also produce oxygen through photosynthesis.

- Algae act as a light filter and diffuser facilitating an even distribution of live food and larvae within the tank system.

- Algae act as a promoter and background for the location of prey organisms, hence playing a particularly important role in the critical first feeding stage of larvae.

- Algae have been shown to stimulate the enzymatic synthesis and onset of feeding in young larvae.

In recent years photo-bioreactor systems have provided an efficient alternative to traditional sack culture systems for the production of unicellular algae. These are labour saving, automated and cost effective. Productivity using these systems can be up to 10 times greater than that achievable with traditional culture methods. Undoubtedly the success of such systems is dependent upon light availability; and the Mediterranean climate is particularly suitable. The search for additional algal species continues, and isolates of local species are being investigated in Norway in an attempt to replace some of the traditional non-indigenous species. In addition, commercial companies are marketing concentrated algal pastes, delivered either alive with a limited shelf life or cryopreserved, which offer a back-up and an alternative to traditional algal production.

The second link of the live food chain is the rotifer. The duration and quantity of rotifers required varies with the species; cod, for example require up to four times the number of rotifers per animal produced when compared to the sea bream. Some species such as the sea bass may avoid this stage altogether first feeding directly on Artemia nauplii, the last link in this chain.

Rotifer production methodologies have improved over the years from an algae and yeast-based diet giving poor productivity and unpredictable results to improved culture diets. The new generation of diets enables culture densities of 2000 rotifers per ml or more to be achieved over a 4-day batch cycle. Further developments have resulted in additional improvements. For example, 5000 rotifers per ml can be achieved using concentrated fresh water chlorella algae and automatic dosing pumps; and recirculation systems using protein skimmers, in association with novel filters enable rotifer cultures to reach and be maintained at densities over 5000 per ml for prolonged periods of time. These developments have been shown to both provide significant economic benefit and importantly improve the microflora of the culture by reducing the incidence of Vibrio spp. (Suantika et al., 2003). Ongoing European Union projects have revealed that there is considerable genetic diversity in the rotifer populations in European hatcheries showing considerable difference in performance. It is not yet clear whether it will be necessary to work with selected genotypes cultured over a limited number of generations or how these cultures will be susceptible to changing culture conditions (Sorgeloos, 2004).

A better understanding of the nutritional requirements of the fish species cultured has led to the development of a number of commercially available cultivation and emulsion type enrichment diets for both rotifers and artemia. Dietary research has indicated the importance of the (n-3) highly unsaturated fatty acids, mainly eicosapentaenoic acid (20:5(n-3), EPA), docosahexaenoic acid (22:6(n-3), DHA) and more recently the long chain n-6 PUFA arachidonic acid (20:4n-6, ARA) has been implicated as an essential fatty acid for a variety of developing marine species (Estevez et al., 1999). It is the bioencapsulation of these (Figure 4) and other essential nutrients through the live feed chain in the ratios required by the species concerned that has led to the alleviation of several problems such as pigmentation and some deformity issues in larval rearing as well as improving survival.

These enrichment products today are available together with products that for Artemia are capable of altering the microbiological characteristics of the hatching and enrichment environments by reducing Vibrio levels to 30% or less of non-treated environments. This development both provides the farmer with custom nutritional packages and helps to reduce the possibility of disease that may be introduced through the live food chain.

Figure 4. The bioencapsulation process.

Larval nutrition and feed technologies

Larval rearing technologies are today highly intensive with up to 250 larvae stocked per litre. Until recently the live food chain was entirely responsible for the nutrition of these larvae until weaning commenced at approximately 30 days post hatch. The role of the live food chain is still vitally important for many species, but the development of a new generation of sophisticated inert co-feeding and replacement diets have enabled the further intensification of the larval rearing process, and considerably reduced reliance upon the live food chain thereby simplifying production methodologies.

Nutrition, health and performance are intimately linked and the industry is placing increasing importance and effort on optimizing formulations and improving ingredient quality including the sourcing of fresh raw materials. A cold extrusion spherizer agglomeration system has been used to produce diets aimed at the complete replacement of the live food chain and they focus on high digestibility. Skretting use the above technology together with a patented phospolipid content of 12%. This has been reported to play an important role in the reduction of juvenile deformation and improved growth performance.

It is hoped that further developments of micronised replacement diets will both simplify and standardize future marine fish larval rearing and enable a greater number of species to be commercialized. Possibly given the restriction of the very small mouth sizes of some marine larvae, such as the groupers, and the difficulty in maintaining extremely small strains of rotifers for first feeding, highly digestible diets of this type may provide an alternative strategy for the industry.

On-growing technologies

European aquaculture is focused on the intensive rearing of fish. Salmon, some trout, sea bass, sea bream and other various round marine fish are grown in floating cage structures. Protected coastline offering abundant site availability in Norway and Scotland led to the development of the cage farming industry. Following the early success and profits made in these areas attention turned to the Mediterranean, in particular the Adriatic, Ionian and Aegean seas where similar coastlines existed. This led to the development of the sea bass and sea bream industry. As these industries developed and juvenile availability increased for each species, the type of these cage structures developed. Initially small wooden structures evolved to larger steel ones with the culture volumes increasing from 125 m3 to 3000 m3.

The need to find additional on-growing sites for expansion and to move away from conflicts with tourism and environmental concerns, particularly in the Mediterranean region, led to the rapid migration of the industry to more off-shore locations. These more remote sites had the advantage of being in deeper water, with better water exchange providing improved growth and hygiene conditions. The structures generally employed were circular polyethylene cages and these were more flexible and better suited to the harsh environmental conditions encountered. In addition, they proved to be less expensive and provided further economies of scale with volumes of 10,000 m3 or more.

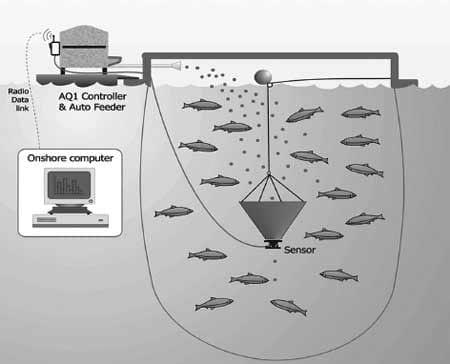

These large cages are today fully automated with computerized air blown feed delivery systems operated from a centrally moored feed barge (Figure 5). Underwater monitoring and surveillance systems enable operators to observe feeding behaviour, fish health status and adjust feed delivery to ensure optimal growth and feed conversion ratios (FCR).

These systems have been found to be suitable for most European weather conditions, however some fully exposed sites are experimenting with submersible cage systems to avoid extreme conditions. These new technologies are primarily being investigated in other areas of the world where tropical storms and the lack of protected coastlines make traditional cage systems impractical.

The future of cage on-growing technologies will continue with the establishment of more offshore cage systems and perhaps even larger structures will be developed to accommodate the requirements of new species such as the tunas.

Land-based on-growing technologies in Europe can be split into open flow through raceway-type systems, commonly used for the production of trout, and recirculation systems for eels, tilapia and turbot amongst others. The flow-through systems may exploit the benefits of waste warm water from power stations where a number of species are cultured including sole, sea bass and sea breams. Semi-intensive pond culture of marine and brackish water species also takes place in Spain and Italy and the pond culture of carps exists in many countries of Europe. Highly intensive land based systems are used for the pre-ongrowing of juvenile sea bass and sea bream in Spain where the rigours of off-shore on-growing systems dictates that the size of the juveniles recruited should be in the order of 20 g. Typically these systems employ liquid oxygen and use where possible borehole water, which has proved to have the benefits of constant temperatures, low bacterial levels and high water quality without the need for expensive pretreatment. Land-based systems are the only effective method of producing some flat fish species; and while in Europe land prices are at a premium, the value and market potential for some species (sole 11 €/kg, whole) is such that significant investment is already underway. The potential for the development of vertically stacked shallow raceway systems controlled by re-circulation technologies is therefore of interest.

Figure 5. Sea cage automated response monitored feeding system (Akvasmart).

On-growing feed technologies

Modern European aquaculture feed production developed in parallel with the needs of the salmon and trout industries. Licensing restrictions based upon feed consumption and waste product release into the environment together with the commercial pressures of feed usage and improved growth rates have resulted in more efficient and cost effective formulations. High energy extruded feeds used in the salmon industry today can contain fat levels of over 30% and feed conversion rates have dropped to below 1:1. The efficiency of these diets has been cross-checked by in vivo testing using mink as a target animal to determine among other things protein digestibility. Excess production capacity in northern European feed mills was quickly adapted to meet the demand of the developing sea bass and sea bream industry in the Mediterranean. Initial pelletized feeds were replaced with extruded diets and formulations adapted to meet the demands of individual species were developed as production grew.

Consumer confidence and food safety issues are important factors in aquaculture. Following the BSE outbreaks, the European Union banned the inclusion of ingredients derived from terrestrial animal byproducts. This has stopped the incorporation of hemoglobin, blood meals, meat, bone and feather meals amongst other ingredients. In addition to this, many sales outlets and the large supermarket chains require European feeds to be certified GMO-free as part of their drive to satisfy consumer demand and perception.

The newly established European Food Safety Authority (EFSA) runs risk analysis and risk management and promotes an integrated approach to the responsibility of feed manufactures, farmers and food operators on the traceability of feeds, food and their ingredients.

These actions, while essential to regulate the industry and address consumer and public health issues, severely restrict the formulations available for aquaculture. This in turn places a heavy load on the limited resource of fish meal as a protein source and adds to the cost of feed at a time when the industry is striving to reduce production costs by all means possible. Fish meal and oil substitutes are emerging now as viable, economic partial alternatives. The inclusion of digestibility enhancers and organic chelated trace minerals provides better bioavailability of important nutrients.

Feed quality may also be affected by poor storage conditions or raw material quality. This can result in the development of mycotoxins that can increase disease sensibility, result in lower growth and poor FCRs (Lovell et al., 1994). Modern natural glucomannan mycotoxin adsorbents are capable of absorbing a broad spectrum of mycotoxins directly from the digestive tract preventing their absorption and subsequent bioavailability.

Health and disease issues

Parasitic, bacterial and viral diseases cause considerable financial loss to the European industry. Disease problems in the marine sector originate from a diverse range of infectious agents, which have been reviewed by Le Breton (1996) and Rodgers and Furones (1998), a list that has rapidly developed and is continually expanding.

The development of molecular techniques for the identification and screening of pathogens offers the potential to improve disease prevention and control. The sensitivity of nucleic acid probes now enables the detection of subclinical carriers of some infections; and this is an important development and tool for the establishment of specific pathogen-free broodstocks. Hatchery production units try to avoid the introduction of opportunistic pathogens through treatment of the incoming water supplies using a variety of filtration methods. Sterilization, either by UV and (or) ozone, is common practice in both freshwater and marine environments. Production scheduling now includes specific periods where either units of, or the whole hatchery are shut down, cleaned and sterilized and all-in-all-out batch production provides regular sanitary control. Areas within the hatchery environment are kept as discrete as possible with the minimum of interaction by working personnel and equipment from one area to another. Isolated quarantine facilities are employed to prevent the introduction of disease.

In larval rearing various strategies have been proposed for controlling the microflora of this environment. Mature water and the addition of probiotics either through the live food chain or directly in the larval rearing tank have been used. The larval pre-feeding and first feeding stages are critical to the establishment of the microflora of the gut. (Bergh et al., 1994; Munro et al., 1993) and the presence of opportunistic pathogens at this stage has been shown to lead to disease (Grisez et al., 1996). Fish transfer from the hatchery to the pre-ongrowing or on-growing facilities necessitates the transfer of fish from a protected to an unprotected environment in which they might come into contact with a variety of different pathogens It is possible to protect against certain diseases with vaccines, and a limited number are available for commercial use. Vaccination takes places prior to the transfer from the hatchery facilities to the on-growing units, but due to the limited duration of protection offered to fish further vaccination may be necessary during the on-growing cycle.

With the complexity of vaccine licensing and the restricted use of antibiotics and some other therapeutic agents the industry is turning to other methods of prophylaxis and control to improve the fish health status. The concept of nutritional supplementation, the use and blending of selected nutrients, immunostimulants and immunomodulators are urgently being considered by the aquaculture industry as it learns of their effectiveness in terrestrial animal culture.

Conclusions

European aquaculture is expected to show growth in the marine sector and the success of individual operations will depend on the successful application of a variety of multidisciplinary activities. Economic viability must be linked to better marketing strategies and food safety. Transparency, traceability, quality and sustainability issues are at the forefront of European concerns and actions. Technological improvements are expected to continue to improve cost efficiency and stimulate further species diversification at a time when fisheries production is stagnant and in certain sectors in decline. Simplified legislation and licensing procedures have been called for and continued and coherent policies for research and development are essential.

References

Author: JOHN W. SWEETMANAgresti, J.J., S. Seki, A. Cnaani, S. Poompuang, E.M. Hallerman, N. Uniel, G. Hulata, G.A.E. Gall and B. May. 2000. Breeding new strains of tilapia: development of an artificial centre of origin and linkage map based on AFLP and microsatellite loci. Aquaculture 185:43-56.

Austin, B. and J.G. Day. 1990. Inhibition of prawn pathogenic Vibrio spp. by a commercial spray-dried preparation of Tetraselmis suecica. Aquaculture 90:389-392.

Bergh, O., K.E. Naas and T. Harboe. 1994. Shift in the intestinal microflora of Atlantic halibut (Hippoglosssus hippoglossus) larvae during first feeding. Can. J. Fish. Aquat. Sci. 51:1899-1903.

Cedra, J., M. Carrillo, S. Zanuy, J. Ramos and M. de la Higuera. 1994. Influence of nutritional composition of diet on sea bass, Dicentrarchus labrax L., reproductive performance and egg and larval quality. Aquaculture 128:345-361.

Cooper, S., A. Battat, P. Marot and M. Sylvester. 1983. Production of antibacterial activities by two bacillariophyceae grown in dialysis culture. Can. J. Microb. 29:338-341.

Estevez, A., L.A. McEvoy, J.G. Bell and J.R. Sargent. 1999. Growth, survival, lipid composition and pigmentation in turbot (Scopthalmus maximus) larvae fed live-prey enriched in arachidonic and eicosapentaenoic acids. Aquaculture 180:321-340.

European Food Safety Authority (EFSA). www.efsa.eu.int. FAO Inland Water Resources and Aquaculture Service. 2003. Review of the state of world aquaculture. FAO Fisheries Circular No. 886, Rev. 2. Rome, FAO, p. 95.

Federation of European Aquaculture Producers (FEAP). www.feap.org.

Grisez, L., M. Chair, P. Sorgeloos and F. Ollivier. 1996. Mode of infection and spread of Vibrio anguillarum in turbot Scopthalmus maximus larvae after oral challenge through live feed. Disease Aquat. Organ. 26:181-187.

Harel, M., A. Tandler, G.W. Kissil and S.A. Applebaum. 1994. The kinetics of nutrient incorporation into body tissues of gilthead sea bream (Sparus aurata) females and the subsequent effects on egg composition and egg quality. Brit. J. Nutr. 72:45-58.

Le Breton A. 1996. An overview of the main infectious problems in cultured sea bass, Dicntrarchus labrax and sea bream Sparus aurata: solutions? In: Sea bass and Sea Bream Culture: Problems and Prospects. Contributions and Short Communications (B. Chatain, M. Saroglia, J. Sweetman and P. Lavens, eds). Presented at an International Workshop, 16-18 October, 1996, Verona, Italy. European Aquaculture Society, Oostende, Belgium, pp. 67-86.

Lovell, R.T., S. Lumlertdacha, B.W. Kemppainen, S.D. Lenz and R.A. Shelby. 1994. Researchers chart mycotoxin problems in channel catfish. Feedstuffs, August 29, pp. 11.

Munro, P.D., T.H. Birkhead and A. Barbour. 1993. Influence of the rate of bacteria colonization of the gut of turbot larvae on larval survival. In: Fish Farming Technology (H. Reinertsen, L.A. Dahle, L. Jorgensen and K. Tvinnereim, eds). A.A. Balkema, Rotterdam, p. 85-92.

Rodgers, C.J. and M.D. Furones. 1998. Disease problems in cultured marine fish in the Mediterranean. Fish Pathol. 33:157-164.

Sorgeloos P. 2004. Quality in live food. Presented at the 3rd Workshop of the PROFET Initiative, ‘Hatchery technologies’. 16-17 January 2004, Bordeaux, France.

Suantika, G., P. Dhert, E. Sweetman, E. O’Brien and P. Sorgeloos. 2003. Technical and economic feasibility of a rotifer recirculation system. Aquaculture 227:173-189.

Tacon, A.J. 2003. Aquaculture production trends analysis. In: FAO Inland Water Resources and Aquaculture Service. Review of the State of World Aquaculture. FAO Fisheries Circular No. 886, Rev. 2. Rome, FAO, p. 95.

Watanabe, T. 1993. Importance of docosahexaenoic acid in marine larval fish. J. World Aquat Soc. 24:152-161.

Zohar, Y. and C.C. Mylonas. 2001. Endocrine manipulations of spawning in cultured fish: from hormones to genes. Aquaculture 197:99-136.

Ecomarine Ltd, Cephalonia, Greece