PRODUCTS & SERVICE WE OFFER

We offer innovative and creative suggestions according to the needs of our clients anywhere by developing of custom engineering design and projects, from a fully integrated technology and service concept to suggestions on how to improve mill output, providing the right equipment to get the job done:

· Project Development

· Engineering-Design of conventional and tailor-made processes and plants

· Special Equipment Development and manufacturing

· Total Equipment-System-Plant supply

· Technical Assistance-Installation

· Turnkey Projects

· Service – Operation – Support and,

Process and Nutrition Technologies with INTEC, one of our business units

History

E.S.E – Engineered System & Equipment is part of Midland Industrial Group. The E.S.E. manufacturing facility at the Industrial Park in Caney, Kansas, was established in mid-1988 to fabricate, manufacture and rebuilt specialized equipment and component parts to be used in connection with processing systems originally designed and sold by its parent company ASIMA Corporation. The company was founded for the purpose of developing and marketing sophisticated and specialized animal, pet, and aquaculture feeds, products by products and waste processing systems.

In 2001 E.S.E. acquired HALVER FORBERG Technology from Demark, for the manufacturing of fluidized latest technology high precision mixing – vacuum coating – Meal Drying Equipment and Systems.

In 2011 E.S.E. acquired PRATER Industry’s EVOLUTION special Grinding Pulverizing Equipment Manufacturing line.

In 2013, E.S.E. acquired AWS ANLSGENTECHNICK of Bremen Hagen, Germany, specialized in high precision dosing and weighing systems, precision micro-ingredient and premix production plants.

Through the years, E.S.E. . has designed, constructed equipment, processing systems and complete plants for export to 6 continents, in more than 40 countries around the world. These extensive projects have provided important experience that enabled E.S.E. to become technically competent and prepared for any size of project, from individual machines or system designs, to complete full scale plant developments and turnkey project installations.

E.S.E.’s continuous and worldwide research and development provide the company’s strengths and core competencies. This includes the number of experience years the corporate staff has directly in the specialized processing equipment and systems industry, including the design and building of complete custom plant facilities. E.S.E. has positioned itself to explore such opportunities and responds to the challenge of our clients and market trends.

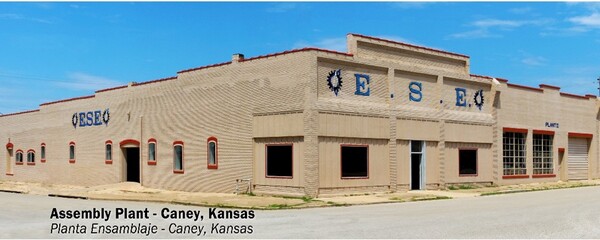

E.S.E. MAIN MANUFACTURING PLANTS & OFFICES.

A wide infrastructure with capacity to produce, rebuilt and store equipment and products. E.S.E. has 3 plant locations which are in Caney, Kansas in the United States:

The main plant is also the corporate headquarters located at the Industrial Park in Caney, Kansas. This plant covers 24,000 square feet which consists of office and an exhibit area, with most of the space being used for manufacturing and warehousing. This is a well-equipped plant located on 14 acres, it has highway access, and the nearest international airport is in Tulsa, Oklahoma.

E.S.E. Pilot Plant & Training Facility

The Pilot Plant is our showroom and showcase of our full lines of processing equipment. We can demonstrate several processing systems including Rolling, Flaking and Grinding. These complete working systems is also used for customers and employees training.

E.S.E. Assembly Plant

The E.S.E. Assembly plant is utilized as our display show room. This plant is large enough for us to display our vast array of equipment pieces for customers to view and inspect. Both the Pilot Plant and the show room Plant are within walking distance of each other in downtown Caney, Ks for convenient customers’ access.