Content sponsored by:

Rossari Biotech Limited

Managing Digestibility- A Key Paradigm to Profitability

Published: May 23, 2022

By: Rossari Biotech Ltd.

Rossari Biotech Limited is one of the India’s leading Enzyme manufactures headquartered in Mumbai, India. The company markets and manufacturers for wide range of industries including the animal health. The prime focus in the animal health is on Gut health and measures to improve the nutrient availability and digestibility through its products which are validated, effective, safe and consistent. With its expanding network in India and across various geographies, Rossari Biotech Animal Health has successfully carved its place in the veterinary industry of India as one of the largest and leading Enzyme manufacturers. We have pioneered in the concept of enzymology and other core chemistry to create solutions with great value preposition.

One of the major focuses for the organization has been to ensure that there are solutions which help the ever-increasing need of the industry to optimise the feed costs by using varied raw materials without compromising the performance. Through its state-of-the-art R&D, Rossari Biotech has come up with solutions to overcome the challenges of high feed cost and negative impact of the non-conventional raw materials.

As the diets are becoming more complex each day, Complex diets containing multiple substrates require a multi-enzyme solution to fetch the desired results. Introduction of alternative low-cost raw materials to diets increases levels of anti- nutrients and enzyme substrates e.g.

- Arabinoxylans in dietary fibre

- Trypsin inhibitors

- Lectins

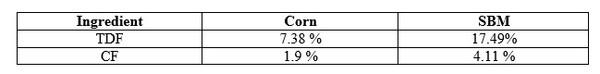

As a general consideration, around 25% of the feed ingredients remain undigested and one of the major reasons for less digestion is the fibre content of feed which is usually calculated as CF by not taking into account the other constituents of the fibre present in the feed. Thus, the CF doesn’t form an actual indicator of the fibre in the feed and TDF is always greater than CF. Conventional raw materials like Soya meal has CF of approx. 4.11% while as the TDF ranges more than 17.49% which accounts to one of the reasons of not allowing complete nutrient utilization.

Similarly for conventional energy sources like Corn, the starch percentage varies from 69 to 73% as per some studies and subsequently digestibility varies from 25% to 56%. Many reports have shown further variation in the level of starch and digestibility in Corn. This further necessitates the use of a solution which will ensure optimization of energy and protein availability from Corn and Soya respectively.

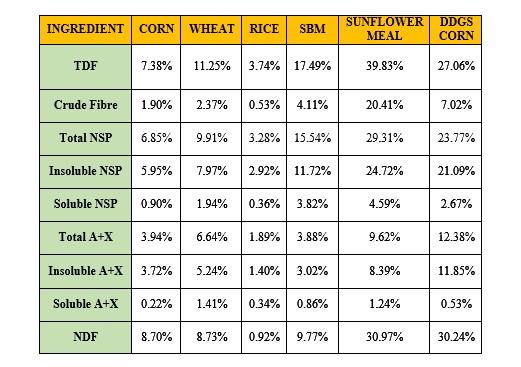

The level of NSP content both soluble and insoluble also plays a very critical role in establishing the nutritive value and digestibility of that raw material. The NSP content in conventional as well as unconventional raw materials is also variable and accounts for the anti-nutritional effects in the body.

To counter such challenges,

Maxizyme EX is one such solution from the house of Rossari Biotech which gives greater scope to the use of non-conventional raw materials without having any negative impact on the performance and health of the birds. Additionally with the conventional diet, it helps in better optimization of nutrient digestibility and ensures cost optimization simultaneously. The nutrient matrix of Maxizyme-EX has been designed through various regression studies making it convenient to be incorporated in the feed formulation.

Maxizyme EX is a highly concentrated and a synergistic combination of various individual enzymes which have been fortified with probiotic strains to potentiate the effect. The enzymes are obtained from the bacterial sources which are tolerant to high temperature ensuring thermostability. The various category of enzymes and their concentration gives a greater leverage to the nutritionists to use varied sources of energy and protein in their formulation. Maxizyme EX is composed of 4 different categories of enzymes as below:

- Mineral Releasing Phytases

- Energy releasing Carbohydrases which specifically target the NSP content of feed

- Energy Sparing Mannanases

- Supplementing enzymes like Proteases and Lipases

The fortification with Probiotic strains helps in creating a favourable environment in the Gut which works in synergy with the enzyme action and helps in better absorption and assimilation of nutrients thereby optimising performance and ensuring profitability.

Maxizyme EX through its various individual enzyme components takes care of negative effects of NSP’s in the diet, reduce the antinutritional effects on trypsin, ensure there is no rapid feed passage and thus less Nitrogen loss and optimal performance. The granulation technology further ensures proper mixability and flowability which reduces the losses incurred during mixing and balance.

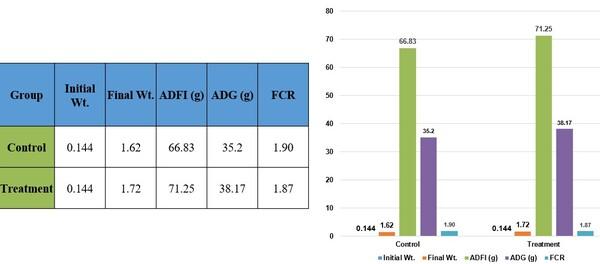

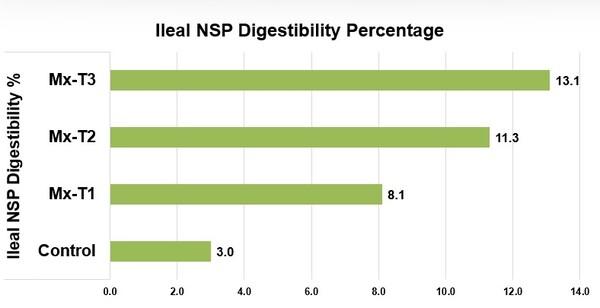

Maxizyme EX can be included in the feed at the dosage of 300-500gm/ton of feed, depending on the type of raw materials used. Our various trials on Maxizyme EX in varied conditions have given us consistent results with better profitability thereby creating a satisfying client base. Some of the results of Maxizyme EX on Ileal digestibility and optimization in performance are mentioned below in Table-1 and Table-2.

Rossari Biotech is committed to add value to your birds and your farm by promoting solutions which ensure profitability amidst adversity as well.

Table-1

Table-2

Related topics:

Influencers who recommended :

Dr. Shambhavi Recommend

Comment

Share

Would you like to discuss another topic? Create a new post to engage with experts in the community.