Growing potential for using dried distillers’ grains with solubles in swine diets

The escalating growth of the fuel ethanol industry in the United States of America continues to increase supplies of dried distillers’ grains with solubles available for use in livestock and poultry feeds. In 2004, there were 81 ethanol plants located in the US that produced a record 3.41 billion gallons of ethanol, a 21% increase over 2003 and representing 109% growth since 2000.

Today there are 86 ethanol plants capable of producing 4.4 billion gallons of ethanol and another 38 plants under construction/ expansion capable of producing an additional 1.7 billion gallons of ethanol. This is a combined production capacity of 6.1 billion gallons of ethanol per year (Renewable Fuels Association, 2006). This growth is expected to continue over the course of the next six years to meet the 8 billion gallon per year target for 2012 set forth in the new Energy Bill.

Corn (maize) is primarily used as the feedstock in ethanol plants because of its highly fermentable starch content. Currently, over 90% of US fuel ethanol is produced from corn. Because of the readily available corn supply in the midwestern US, many ethanol production facilities have also been built in this region. In 1981, ethanol production used 86 million bushels of corn, however in 2004 corn use for ethanol had risen to over 1.4 billion bushels and has remained at 10% or more of total US corn production since 2002 (Renewable Fuels Association, 2005).

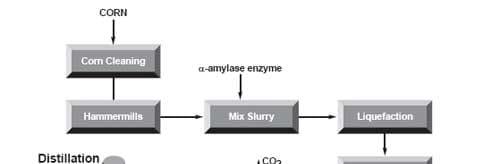

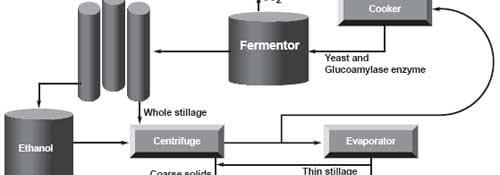

The majority of fuel ethanol is produced from dry-grind ethanol plants, which represent the fastest growing sector of the fuel ethanol industry in the US. Other products besides ethanol from dry-grind ethanol plants include distillers’ grains (wet or dry), typically with the soluble portion added back (Figure 1).

In 2004 these dry mills produced more than 8.05 million tons of distillers’ dried grains with solubles (DDGS). With continued growth, industry experts are predicting that DDGS production will exceed 11 million tons by 2008. The majority of distillers’ grains are fed to beef and dairy cattle. However there is an increasing amount fed to poultry and swine. Traditionally, distillers’ grains have been fed to ruminants because of the low protein and high fiber content, which made distillers’ grains more attractive for cattle than pig diets.

However, modernized engineering of ethanol plants with new technologies, processing techniques and better quality control, have led to improved DDGS nutrient profiles that have gotten the attention of swine diet formulators. In addition, the large number of new ethanol plants have increased the amount of distillers’ grains available on the market and made it economically attractive for a wider range of diets.

Figure 1. Animal feed co-products of dry mill ethanol production.

Challenges and opportunities in using DDGS

VARIABILITY

One of the challenges of using corn distillers' grains in diets for swine is knowing the nutrient content of the specific ingredient source. A study by Spiehs et al. (2002) showed that the nutrient content of corn DDGS can vary among ethanol plants and over time within the same plant. Values listed in Table 1 illustrate the amount of variation that occurs in DDGS (Shurson et al., 2005).

Many people believe the variation in nutrient content of corn distillers' grains with solubles is related to the normal variation among corn varieties and geographic location.

A study by Goodson (2006) showed that the CV for crude protein in corn was 7.8% among midwestern states. This illustrates that because the nutrients in corn become concentrated by approximately 3-fold, it is not unexpected that the variability of nutrients among DDGS sources is also increased.

However, in a study by Belyea et al. (2004), variation in the composition of DDGS at a single modern ethanol production facility was shown to be unrelated to the variation in the composition of the corn. They speculated that the rate in which the soluble portion of the fermentation by-product is added back to the grains fraction induced the variation that is found in DDGS.

Table 1. Averages and ranges in selected nutrients (dry matter basis) among 32 US corn DDGS sources.

Adapted from Shurson et al., 2005

Knott et al. (2002) evaluated the nutrient composition of the grains and soluble portion produced during the ethanol dry-grind process. They found that the grains fraction was less variable than the solubles fraction and concluded that the amount of solubles added to the grain fraction has a significant effect on final DDGS nutrient composition.

One drawback of this study was that they collected and evaluated samples from wet grains and solubles. The nutrient profile of these fractions may change after they have been dried using conventional commercial dryers. Nutrients within these fractions may volatilize, become bound by Maillard reactions, or precipitate. This would lead to greater variation in DDGS nutrient fractions. The blending ratio of condensed distillers' solubles to the grains fraction to produce DDGS also varies among plants.

Some add all of the condensed solubles produced to the grains fraction before drying, while others may add substantially less. This practice significantly changes the nutrient composition of the final DDGS. These all contribute to the degree of variability found in DDGS and illustrate the importance of finding a high-quality, single source and monitoring product quality and composition.

COST EFFECTIVENESS

Factors that influence cost effectiveness of including DDGS in swine diets are its price relative to corn, the energy value of DDGS, and phosphorus price. In fixed marketing systems, the breakeven price for DDGS depends heavily on the assumed energy value because of the direct relationship of energy on pig growth rate. Spiehs et al. (2002) and Hastad et al. (2004) have shown that the energy of DDGS from newer ethanol plants is similar to corn (3,521 and 3,697 kcal of ME/kg, respectively).

Another trait of DDGS that adds value is the amount and form of phosphorus it provides. DDGS contains both higher amounts of phosphorus and it is more bioavailable.

In poultry, availability of phosphorus in corn DDGS was calculated by Lumpkins and Batal (2005) to be 54 to 68%. Martinez et al. (2004) computed phosphorous availabilities of 69, 75, 82, and 102% for different DDGS samples and suggested that heat processing increased phosphorus availability. In swine, Whitney et al. (2001a) showed phosphorus in DDGS to be about 90% available in two studies. Typical corn dried distillers' grains with solubles contains 0.70% available phosphorus. This reduces the amount of supplemental inorganic phosphorus needed in diets as well as reducing phosphorus excretion in manure.

With an improved nutrient profile and more attractive cost, DDGS is being used more frequently in swine diets. At current ingredient prices in the US midwest (corn, $64.90/ T; soybean meal, $198/T, limestone, $75/T; and monocalcium phosphate (21% P), $300/ T), DDGS will provide approximately a $0.78 per ton savings when added at 10% of the diet. Historically the use of 10% DDGS in swine diets has saved as much as $2.00/ ton of complete feed. Currently, DDGS is used at 8 to 15% in swine grow-finish feed programs across Minnesota, Wisconsin, Iowa, Illinois, South Dakota and Nebraska.

GROWTH PERFORMANCE AND CARCASS TRAITS

Several studies conducted in recent years have shown mixed results with inclusion of DDGS in swine diets. A possible explanation for differences among studies is differences in DDGS source and product variability. These studies have shown that as level of DDGS in the diet increases, there is a decrease in average daily gain and feed intake (Whitney and Shurson, 2004; Fu et al., 2004) with little or no difference in feed efficiency.

However, Cook et al. (2005) showed that DDGS could be added at 10, 20 or 30% of grow-finish pig diets with no difference in ADG, ADFI or feed efficiency. Another commercial study by DeDecker et al. (2005) showed no negative effect on intake when DDGS was added at 30% of the diet.

While many production systems and feed companies use DDGS, they typically limit DDGS inclusion to less than 15% of the diet. Higher levels are seldom utilized because of reductions in feed intake, economics, or carcass traits. The inclusion of DDGS has been shown to reduce ADFI in field and research conditions. Work by Hastad et al. (2005) evaluated effects of DDGS source, level, processing technique, and compounds on feed intake in swine. In these studies pigs preferred to consume diets without DDGS.

Similar work with sorghum DDGS by Senne et al. (1996) showed increasing sorghum DDGS from 20 to 60% of the diet linearly decreased ADFI for both nursery and finishing pigs.

Studies have also shown that DDGS addition to swine diets can influence carcass traits. Whitney et al. (2001) showed that increasing DDGS from 0 to 30% did not alter muscle quality or carcass lean percent. However, dressing percent decreased with increasing dietary DDGS level, slaughter weight was lower for pigs fed 20 or 30% DDGS, belly firmness decreased and iodine value increased. Similar carcass trait responses were shown by Cook et al. (2005), who noted that as DDGS increased from 0 to 30% of the diet, carcass yield decreased linearly without effect on back fat or carcass lean.

Effects of DDGS inclusion rate on carcass yield should be considered when evaluating the economics of its use. Also, the effects of feeding DDGS on pork fat quality are generally not a concern unless other sources of unsaturated fat are also included in the diet. Traditionally meat processors have not penalized soft bellies (high iodine value), but penalties for soft bellies may be implemented in the near future. This could make it difficult to use moderate levels of DDGS with other unsaturated fat sources.

While diet cost savings may be realized, effects on carcass traits and subsequent carcass value need to be evaluated to ensure that the DDGS use has a net positive effect on pig revenues.

| Conclusions The continued growth of the fuel ethanol industry will provide increasing amounts of corn DDGS available to the feed industry. Using DDGS from a single source and monitoring quality will help minimize variability while providing valuable nutrients such as energy and phosphorus in swine diets. It is important to evaluate the economic impact of DDGS inclusion on feed cost as well as its effect on market weight and carcass value. Importantly, the value of co-products produced by the fuel ethanol industry will be essential to its sustainability. This underscores the need for ethanol facilities to increase the value of co-products by providing consistent, utilizable products that are important to production animal agriculture. |

References

Belyea, R.L., K.D. Rausch and M.E. Tumbleson. 2004. Comparison of corn and distillers’ dried grains with solubles from dry grind ethanol processing. Biores. Technol. 94:293- 298.

Cook, D., N. Paton and M. Gibson. 2005. Effect of dietary level of distillers' dried grains with solubles (DDGS) on growth performance, mortality and carcass characteristics of grow finish barrows and gilts. J. Anim. Sci. 83( Suppl. 1):490.

Fu, S.X., M. Johnston, R.W. Fent, D.C. Kendall, J.L. Usry, R.D. Boyd and G.L. Allee. 2004. Effect of corn disillers’ dried grains with solubles (DDGS) on growth, carcass characteristics and fecal volume in growing-finishing pigs. J. Anim. Sci. 82(Suppl. 2):207.

Goodson, J. 2006. Degussa Feed Additives Corn/Soy Report 2005. Kennesaw, GA.

Hastad, C.W. , M.D. Tokach, J.L. Nelssen, R.D. Goodband, S.S. Dritz, J.M. DeRouchey, C.N. Groesbeck, K.R. Lawrence, N.A. Lenehan and T.P. Keegan. 2004. Energy value of dried distillers' grains with solubles in swine diets. J. Anim. Sci. 83(Suppl. 2):208.

Hastad, C.W., J.L. Nelssen, R.D. Goodband, M.D. Tokach, S.S. Dritz and J.M. DeRouchey. 2005. Adding dried distillers' grains to swine diets affects feed preference. Kansas State University Swine Day 2005. Report of Progress 964, pp. 149-159.

Knott, J., J. Shurson and J. Goihl. 2002. Effects of the nutrient variability of distillers’ solubles and grains within ethanol plants and the amount of distillers’ solubles blended with distillers’ grains on fat, protein and phosphorus content of DDGS. Available: http://www.ddgs.umn.edu/articles-quality/nutrientvariability.pdf. Accessed January 9, 2005.

Lumpkins, B. and A. Batal. 2005. Bioavailability of lysine and phosphorus in distillers' dried grains with solubles. Poult. Sci. 84:581-586.

Martinez Amezcua, C., C.M. Parsons and S.L. Noll. 2004. Content and relative bioavailability of phosphorus in distillers' dried grains with solubles in chicks. Poult. Sci. 83:971-976.

Renewable Fuels Association (RFA). 2005. Annual Industry Outlook. ‘Homegrown for the Homeland’. Available: http://www.ethanolrfa.org/industry/outlook/. Accessed Dec.18, 2005.

Renewable Fuels Association (RFA). 2006. Plant Location List. Available: http:// www.ethanolrfa.org/industry/locations/. Accessed January 9, 2006.

Senne, B.W., J.D. Hancock, I. Mavromichalis, S.L. Johnston, P.S. Sorrell, I.H. Kim and R.H. Hines. 1996. Use of sorghum-based distillers' grains in diets for nursery and finishing pigs. Kansas State University Swine Day 1996. Report of Progress 772, pp. 140-145.

Shurson, J., Noll, S. and Goihl, J. 2005. Corn by-product diversity and feed value to non-ruminants. Proceedings 2005 MN Nutrition Conf., September 20-21, St Paul, MN.

Spiehs, M.J., M.H. Whitney and G.C. Shurson. 2002. Nutrient database for distillers’ dried grains with solubles produced from new ethanol plants in Minnesota and South Dakota. J. Anim. Sci. 80:2639.

Whitney, M.H., M.J. Spiehs and G.C. Shurson. 2001a. Availability of phosphorus in distillers’ dried grains with solubles for growing swine. J. Anim. Sci. 79(Suppl. 1):108.

Whitney, M.H., G.C. Shurson, L.J. Johnston, D. Wulf and B. Shanks. 2001b. Growth performance and carcass characteristics of grow-finish pigs fed increasing levels of distillers’ dried grains with solubles. J. Anim. Sci. 79(Suppl. 1):108.

Whitney, M.H. and G.C. Shurson. 2004. Growth performance of nursery pigs fed diets containing increasing levels of corn distillers’ dried grains with solubles originating from a modern Midwestern ethanol plant. J. Anim Sci. 82:122-128.

.jpg&w=3840&q=75)