Freezing Process Benefits Hog Manure Treatment

Published: August 13, 2008

By: Jamie Wuite - Published on the Government of Alberta Agriculture, Food and Rural Development website

About the Study

Treatment of wastewater heavily loaded with organic material, such as liquid hog manure, presents a number of challenges. The high levels of nutrients in the wastewater defy all treatments in achieving full removal, and the decomposition of the organic material rapidly consumes the oxygen in the water. This causes the process to become anaerobic and to give off highly objectionable odours.

A new treatment for organic wastes, named SnowfluentTM, had not previously been tested on liquid hog manure, but its potential for reducing odours was promising. The system sprays the wastewater into cold air under high pressure, freezing it into ice crystals.

The benefits of freezing contaminated water into tiny droplets have been known for some time. Many dissolved compounds precipitate out of the water. Volatile gases, like ammonia, are released into the atmosphere. Freezing also causes cell-wall rupture of bacteria and other disease-causing organisms, thereby making them harmless.

Further beneficial physical and chemical changes occur in the snowpack as it ages and is exposed to fluctuations in temperature, humidity and solar radiation. As temperatures warm up, the snowpack materials separate. Meltwater runs off, leaving a nutrient-rich residue with almost no odour.

An economical system for using this process, called Atomizing Freeze-CrystallizationTM (AFC), was developed about 20 years ago by Delta Engineering Ltd. of Ottawa, Canada, with the cooperation of the Ontario Ministry of the Environment.

Delta now owns worldwide patents on the process and has built a number of permanent Snowfluent plants in Canada and the United States, principally for the treatment of urban sewage wastes. A fully portable Snowfluent plant is also available for small operations, emergency uses, and short-term study projects.

Such a study was undertaken in 1997, with funding provided by the Conservation and Development Branch of Alberta Agriculture, Food and Rural Development (AAFRD), the research committee of the Alberta Pork Producers Development Corporation, and Delta Engineering Ltd., in partnership with the Alberta Research Council. The study's objective was to determine if Snowfluent technology could be used to meet the needs of Alberta's growing pork production industry for a manure treatment system that reduces odours, has no discharge to surface waters, and could recycle the nutrients and water in the hog manure effluent for further agricultural use.

What did We Learn from the Pilot Project?

The Snowfluent process had been previously tested and used for municipal sewage treatment and food processing plant wastewater, but had not been used for liquid hog manure. Thus this pilot study was designed to answer three specific questions:

1. What degree of treatment is achieved using AFC technology to treat liquid hog manure?

2. At what phase in the process do most of the contaminant reductions and other changes

take place?

3. Is there any health risk to operators during the snowmaking process?

1. Degree of treatment achieved

The results of the study showed the Snowfluent treatment had many benefits. Odours from the snowpack were much less than from the lagoon, and were minimal in the meltwater. The solid residue left after runoff had noticeably less odour than conventionally treated liquid or solid manures.

Because Snowfluent technology is used only during the winter, the odours that are produced are less likely to be a problem, as fewer people are outside. Snowfluent treatment also facilitates a shift in labour and equipment, from spring or fall, traditional manure spreading seasons, to winter, when farmers are least busy.

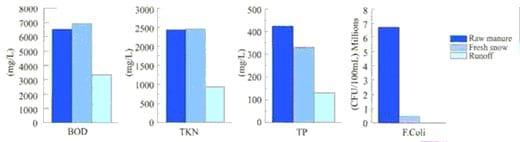

Total nitrogen levels underwent a 61% reduction, from 2431 mg per litre in the raw manure, to 946 mg per litre in the runoff. Total phosphorus levels dropped 69% from the raw manure to the snow pack meltwater. Faecal coliforms were almost totally removed, and biochemical oxygen demand was reduced from 6524 mg per litre to 3360 mg per litre - almost 50%.

2. Phases of treatment

For most parameters tested, the greatest contaminant reductions took place during the aging of the snowpack. However, a great deal of the water loss occurred during the atomization phase, through evaporation and sublimation of the ice crystals. While the water loss itself is probably not a concern, it does have the effect of concentrating the levels of some contaminants in the snowpack phase.

Approximately 70-80% of the nitrogen content of the raw manure was lost during the atomization/crystallization phase, mostly in the form of ammonia which volatilized into the air. The heavy nitrogen losses would probably have been reduced had the treated effluent contained more manure solids. These nutrient losses, which decrease the value of the wastewater as a fertilizer, may be economically significant to producers.

During snowmaking, there were significant levels of odour within the snow plume. At a distance of 30 metres from the plume, however, the odours were minimal. Though the surface odour of the snowpack decreased as the snow aged, a strong ammonia smell was released when deeper layers of the pack were exposed.

As the weather warms, the top of the snowpack is exposed first to melting conditions. Melt water moves down through the pack, picking up soluble compounds, before exiting at the snow/soil interface. As the study showed, the first 30% of the meltwater volume contains 55-80% of the contaminant load. This suggests that at a production scale, the initial concentrated runoff should probably be returned to the lagoon, and only the cleaner second phase of the runoff should be recycled to a holding pond for further use.

In effect, the melting of the Snowpack generates three separate products: an initial, small volume of highly concentrated meltwater; a subsequent large volume of relatively dilute meltwater; and a highly concentrated, lightweight, solid residue. The more concentrated meltwater and solid residues can be applied to the land, with a significant reduction in transportation and spreading costs. The large volume of dilute meltwater can be re-used in the barns for manure flushing, reducing the amount of fresh water needed for the operation.

In fact, the highly concentrated nature of liquid hog manure does not allow for its release to surface water bodies, or its land application on frozen soils, after most treatments. However, Snowfluent treatment can reduce the cost of transporting and spreading large volumes of waste.

3. Operator safety

The air within the plume and immediately downwind of the snowmaking guns also had high levels of bacteria, faecal coliforms and faecal enterococci. Bacteria levels immediately downwind of the guns were similar to levels found in swine confinement barns. Generally, there is little need to work in or near the plume and use of standard protective breathing equipment would eliminate any associated health risks.

How was the Study Conducted?

A hog farm near Sylvan Lake, Alberta, was originally selected as the study site, but due to unseasonably warm weather the test was moved to the Dana Giebelhaus farm near Vegreville. A test site, 15 metres square, was prepared, using square hay bales as a berm and an impenetrable geotextile liner over both the bales and the plot. The site was positioned so the natural slope of the ground would direct meltwater toward an outlet, equipped with sampling and measuring devices.

Raw liquid manure was pumped directly from a storage lagoon to the mobile Snowfluent plant. Because equipment to agitate and homogenize the manure was unavailable, it was decided to use just the liquid at the top 45 centimetres of the lagoon, leaving the manure solids at the bottom. Snowmaking began on the evening of February 26 and ceased on the morning of February 28th, 1997. Approximately 284,000 litres of effluent were processed in that time. As daytime temperatures were higher than the maximum of -6 degrees C considered desirable for the process, snowmaking was restricted to the hours of 9:00 p.m. to 6:00 a.m. The resultant Snowfluent snowpack covered the plot about three metres deep.

Samples were taken of the raw liquid manure and the freshly made snow throughout the course of the snowmaking. The air around the site was also sampled for airborne bacteria. Samples of the meltwater were taken throughout the thaw period, from about the last week of March until the last week of April. The amount of natural precipitation was deducted from the runoff measurements. When runoff ended, the residue remaining on the liner was also measured and analyzed for nutrients and contaminants.

Samples of the new Snowfluent snow were collected by placing a lined tray beneath the plume, then emptying the snow into appropriate containers. Samples of the aging snowpack were taken at three depths and two different locations on the plot. In total, 62 samples were analyzed from all phases of the operation.

Water and Snowfluent snow samples were analyzed for biochemical oxygen demand, nutrients, routine chemistry, and coliform bacteria.

BOD and contaminant reductions during different phases of the Snowfluent process

How does Snowfluent Compare Economically with other Liquid Manure Treatments?

Economic comparisons of Snowfluent technology with conventional spreading and direct liquid injection methods of treatment were generally favorable, though the number of variables involved made specific cost analyses difficult.

Comparisons were based on the Giebelhaus farm, a 300 sow operation, and would be different for larger or smaller operations.

Manure production from the Giebelhaus operation was estimated at 2.8 million gallons per year. Because the capacity of the lagoon is only 1.5 million gallons, manure spreading is done in both fall and spring. Both operations are done by a custom operator, using two of the farms tractors.

The cost of the two operations prior to the Snowfluent test totalled $25,748, including the custom operators fee, an estimated rental fee for the tractors, and the estimated cost of incorporating the manure into the land. Adjustments have not been made for losses in nutrients due to delays in incorporating the manure, nor has a cost been assigned to odour problems inherent in spreading.

Direct injection of liquid manure eliminates the odours associated with conventional spreading, at a slightly higher cost. Based on rates obtained from custom manure injection operators, the total cost of this method of treatment would be $26,705, including an estimated fee for tractors to power the pumps. Little or no nitrogen is lost during injection. Like spreading, direct injection requires year-round lagoon storage or needs to be done twice a year.

Total cost of the Snowfluent treatment was $20,366, based on rates charged by Delta at the time of the study, not including the cost of spreading the residues. For operations where the disadvantages and costs of handling large volumes of liquid manure outweigh its fertilizer value, the loss of ammonia in the snowmaking process may be a minor issue.

However, for farmers who value the ammonia and are intent on retaining the maximum amount of ammonia, the loss of 70-80% of the liquid manures original nitrogen content is significant. Replacing the fertilizer value of the ammonia could push the total cost of the Snowfluent treatment up an additional 30%, depending on current prices and the farmers need for additional nutrients in the soil. It should be noted that nitrogen losses are also significant in conventional treatment systems.

Conclusions and Recommendations

Based on the results of the pilot study, Snowfluent is a viable manure treatment option for Alberta's hog producers. Snowfluent significantly reduces odours in the treated water and solids, and eliminates faecal bacteria.

Snowfluent offers winter treatment options which are otherwise lacking in the industry. Such winter treatment would reduce the need to spread liquid manure early in the spring, when lagoons are full, and would reduce odour events at ice break-up on lagoons. However, the process needs temperatures of -6 degrees C or less, and warm winters will limit snowmaking opportunities.

Costs compare favourably to other treatment options, especially those aimed primarily at reducing odours.

Given the positive results of this study, a production-scale test of Snowfluent technology on liquid hog manure is warranted. Such a study should investigate methods to make the process operate more efficiently and maximize the nutrient value retained in the solid residue.

A more quantitative analysis of atmospheric inputs and odours would also be valuable.

This fact sheet is one of a series of special research bulletins on agriculture and resource management produced by Alberta Agriculture and Food.

The cooperation and assistance of the Giebelhaus family of Vegreville, the Matejka family of Sylvan Lake, and Ed Schultz, Doug Hall and Blaine Middleton of the Alberta Pork Producers Development Corporation are gratefully acknowledged.

SnowfluentTM and Atomizing Freeze - CrystallizationTM are registered trademarks of Northern Watertek Corporation.

Related topics

Recommend

Comment

Share

Would you like to discuss another topic? Create a new post to engage with experts in the community.