Pellet Quality Performance Tests: Milling to Bird Performance

Published: February 4, 2014

By: Joe Moritz, Professor and State Extension Specialist,Feed Manufacture and Poultry Science, West Virginia University

Pellet quality provided to meat birds throughout the industry is highly variable. Feeding birds pellets of poor quality can in part be attributed to an emphasis on pellet mill throughput to generate adequate feed volume. However, perhaps a more compelling reason that feeding poor quality pellets is permitted is the lack of understanding associated with the relationship between pellet quality, bird performance, and economic impact.

Reasons for lack of understanding

Over the years, little progress has been made towards convincing the meat bird industry that feeding high quality pellets has justifiable advantages for bird performance and overall economics. This lack of progress may be attributed to conflicting results in commercial practice and past literature, variables per se and confounding variables that are not accounted for in commercial practice and past literature, and the fact that few companies and universities conduct feed manufacture and feeding research. The following are scenarios that demonstrate how confounding variables can lead to conflicting results:

Reasons for lack of understanding

Over the years, little progress has been made towards convincing the meat bird industry that feeding high quality pellets has justifiable advantages for bird performance and overall economics. This lack of progress may be attributed to conflicting results in commercial practice and past literature, variables per se and confounding variables that are not accounted for in commercial practice and past literature, and the fact that few companies and universities conduct feed manufacture and feeding research. The following are scenarios that demonstrate how confounding variables can lead to conflicting results:

- If thermally gentle manufacturing techniques are utilized (low conditioning temperature, thin pellet die, fast production rate, high pre-pellet (mixer-added) fat application, etc.) that create pellets of poor quality but maintain high nutrient availability then performance may be at an acceptable level and pellet quality could be viewed as not having importance.

- If thermally harsh manufacturing techniques are utilized (high conditioning temperature, thick pellet die, slow production rate, high post-pellet fat application, etc.) that create pellets of high quality but decrease nutrient availability then expected performance benefits may not be observed and pellet quality could be viewed as not having importance.

- If pellets of high quality are manufactured using techniques that do not decrease nutrient availability then performance improvements may be attained and pellet quality could be viewed as having importance.

This publication will summarize recent research generated with current genotypes that accounts for feed manufacture effects on both physical form and nutrient availability.

Feed form independent of nutrient availability

A more accurate assessment of feed form effects can be attained if all feed to be used in a research study is made using the same manufacture techniques so that effects on nutrient availability are consistent, then a portion of that feed is ground and utilized as a treatment.

Feed form independent of nutrient availability

A more accurate assessment of feed form effects can be attained if all feed to be used in a research study is made using the same manufacture techniques so that effects on nutrient availability are consistent, then a portion of that feed is ground and utilized as a treatment.

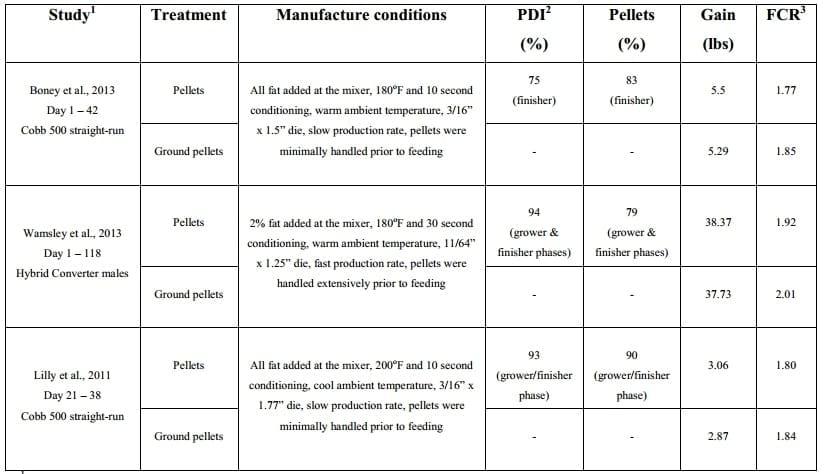

Table 1. Recent data demonstrating benefits of feeding pellets relative to ground pellets

1All diets were formulated to meet or exceed breeder recommendations and were corn/soybean meal based.

2Pellet durability index was determined by placing 500 g of sifted pellets into a Pfost tumbler. Samples were tumbled for 10min at 50 rpm. The sample was sifted again and weighed. Pellet durability index was calculated as the percentage of sifted pellets retained after tumbling.

3Feed conversion ratio was corrected using mortality weights.

2Pellet durability index was determined by placing 500 g of sifted pellets into a Pfost tumbler. Samples were tumbled for 10min at 50 rpm. The sample was sifted again and weighed. Pellet durability index was calculated as the percentage of sifted pellets retained after tumbling.

3Feed conversion ratio was corrected using mortality weights.

Nutrient availability independent of feed form

A more accurate assessment of nutrient availability effects can be attained if all feed to be used in a research study is made using similar lots of ingredients, different manufacture techniques, and all feed being ground prior to feeding to eliminate feed form effects.

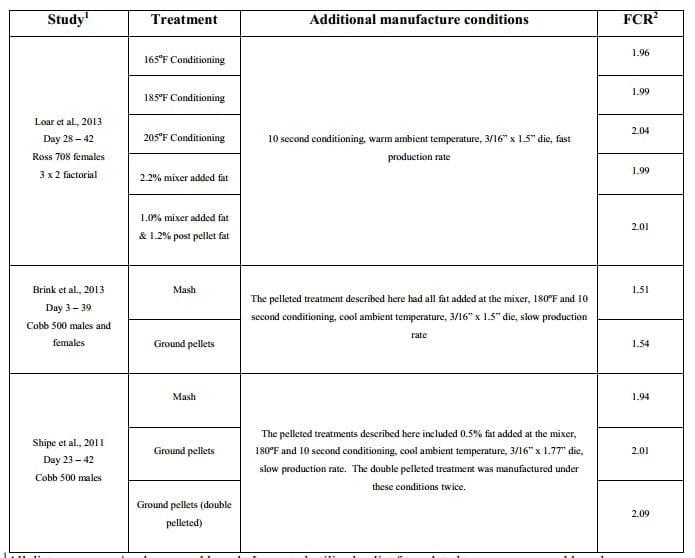

Table 2. Recent data demonstrating detriment to nutrient availability due to pelleting. The physical form of all treatments was standardized by grinding prior to feeding.

A more accurate assessment of nutrient availability effects can be attained if all feed to be used in a research study is made using similar lots of ingredients, different manufacture techniques, and all feed being ground prior to feeding to eliminate feed form effects.

Table 2. Recent data demonstrating detriment to nutrient availability due to pelleting. The physical form of all treatments was standardized by grinding prior to feeding.

1All diets were corn/soybean meal based. Loar et al utilized a diet formulated to meet or exceed breeder recommendations that contained 4% distillers dried grains and solubles; Shipe et al utilized a diet formulated to 90% digestible Lysine levels of breeder recommendations and contained bakery byproduct meal.

2Feed conversion ratio was corrected using mortality weights.

2Feed conversion ratio was corrected using mortality weights.

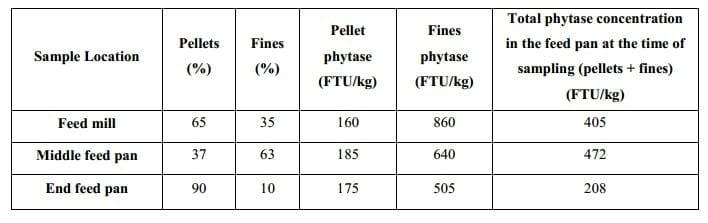

Feed form, ingredient, and nutrient segregation

The effects of pellet quality on ingredient and nutrient segregation are seldom accounted for in past research. Pellets and fines segregate within feed bins as well as during their conveyance throughout a house. If ingredients and nutrients vary between pellets and fines then birds within different locations of the house will consume different nutrient concentrations. This problem would likely be exacerbated when poor quality pellets are produced and liquid ingredients are applied post-pelleting. Collaborative research currently being conducted at West Virginia and Mississippi State Universities will attempt to better define segregation conditions and understand subsequent feeding effects. One replicate from our data set is included below as an example. In this example, phytase was applied post pelleting and samples were obtained from the feed mill and tracked to a commercial house.

Table 3. Pellet, fines, and phytase concentrations from the feed mill to the feed pan.

The effects of pellet quality on ingredient and nutrient segregation are seldom accounted for in past research. Pellets and fines segregate within feed bins as well as during their conveyance throughout a house. If ingredients and nutrients vary between pellets and fines then birds within different locations of the house will consume different nutrient concentrations. This problem would likely be exacerbated when poor quality pellets are produced and liquid ingredients are applied post-pelleting. Collaborative research currently being conducted at West Virginia and Mississippi State Universities will attempt to better define segregation conditions and understand subsequent feeding effects. One replicate from our data set is included below as an example. In this example, phytase was applied post pelleting and samples were obtained from the feed mill and tracked to a commercial house.

Table 3. Pellet, fines, and phytase concentrations from the feed mill to the feed pan.

Conclusion

Feeding high quality pellets provides performance advantages in modern meat bird genotypes; however, benefits are dependent upon manufacturing techniques having a minimal impact on decreasing nutrient availability. Thus far, research has indicated that manufacturing technique can decrease amino acid digestibility (Loar et al., 2013, Corey et al., 2013, and Lilly and Moritz, 2012 ), enzyme efficacy (Lamp and Moritz, 2013, Abdollahi et al., 2013, and Beaman et al., 2012), and the protein to energy ratio (Greenwood et al., 2004, McKinney and Teeter, 2004, Jensen et al., 1965). High quality pellets also have potential to provide performance and flock uniformity benefits by decreasing ingredient and nutrient segregation.

References

Abdollahi, M.R., V. Ravindran, and B. Svihus. 2013. Pelleting of broiler diets: An overview with emphasis on pellet quality and nutritional value. Animal Feed Science and Technology Vol. 179, Issue 1, Pages 1-23.

Beaman, K.R., K.G.S. Lilly, C.K. Gehring, P.J. Turk, and J.S. Moritz. 2012. Determining the efficacy of an exogenous enzyme cocktail post pelleting using broiler performance and metabolism. J. Appl. Poult. Res. 21:744-756.

Boney, J.W., A.E. Evans, and J.S. Moritz. 2013. The effect of feed form and experimental unit size on broiler performance research. Unpublished data. West Virginia University.

Brink, A.L. and A.E. Evans, P.J. Biggs, and J.S. Moritz. 2013. The effect of feed processing, protease efficacy, and bird sex on performance, yield, and digestibility of broiler chickens. Unpublished data. West Virginia University.

Corey, A.M., K.G.S. Wamsley, T.S. Winowiski, and J.S. Moritz. 2013. The effect of calcium lignosulfonate, mixer-added fat, and feed form on true amino acid digestibility and digesta viscosity. Vol 92 (Suppl. 1): 24.

Greenwood, M.W., P.M. Clark and R.S. Beyer. 2004. Effect of feed fines on level of broilers fed two concentrations of dietary lysine from 14 to 30 days of age. International Journal of Poultry Sci. 3 (7):446-449.

Jensen, L.S., G.O. Ranit, R.K. Wagstaff and J. McGinnis. 1965. Protein and lysine requirements of developing turkeys as influenced by pelleting. Poult. Sci. 44:1434-1441.

Lamp, A.E., and J.S. Moritz. 2013. The effects of pelleting and glucanase supplementation in barley based diets on feed manufacture, broiler performance, and gut viscosity. Poultry Sci. Vol 92 (Suppl. 1): 104.

Lilly, K.G.S., C. K. Gehring, K. R. Beaman, P. J. Turk, M. Sperow, and J. S. Moritz. 2011. Examining the relationship between pellet quality, broiler performance, and bird sex. J. Appl. Poult. Res. 20: 231-239.

Lilly, K.G.S. and J.S. Moritz, 2011. Resolving pellet quality issues and improving poult performance with the manufacture of commercial turkey diet formulations. Poultry Sci. Vol. 90 (Suppl. 1): 388.

Loar, R.E., K.G.S. Wamsley, A.Evans, J.S. Moritz, and A. Corzo. 2013. Effects of varying conditioning temperature and fat application on a broiler finisher diet. Poultry Sci. Vol 92 (Suppl. 1): 190. McKinney, L.J. and R.G. Teeter. 2004. Predicting effective caloric value of nonnutritive factors: I. Pellet quality and II. Prediction of consequential formulation dead zones. Poult. Sci. 83:1165-1174.

Shipe, K.J. and J.S. Moritz, 2011. Effect of feed manufacture techniques that vary feed exposure to pellet die heat and pressure on pellet quality and subsequent broiler lysine utilization. Poultry Sci. Vol. 90 (Suppl. 1): 389.

Wamsley, K.G.S. and J.S. Moritz. 2013. D1-42 yeast product inclusion and D42-118 feed form effects on large tom performance using feed produced at a commercial feed mill. Poult. Sci. 92 (E-suppl. 1): 220.

Feeding high quality pellets provides performance advantages in modern meat bird genotypes; however, benefits are dependent upon manufacturing techniques having a minimal impact on decreasing nutrient availability. Thus far, research has indicated that manufacturing technique can decrease amino acid digestibility (Loar et al., 2013, Corey et al., 2013, and Lilly and Moritz, 2012 ), enzyme efficacy (Lamp and Moritz, 2013, Abdollahi et al., 2013, and Beaman et al., 2012), and the protein to energy ratio (Greenwood et al., 2004, McKinney and Teeter, 2004, Jensen et al., 1965). High quality pellets also have potential to provide performance and flock uniformity benefits by decreasing ingredient and nutrient segregation.

References

Abdollahi, M.R., V. Ravindran, and B. Svihus. 2013. Pelleting of broiler diets: An overview with emphasis on pellet quality and nutritional value. Animal Feed Science and Technology Vol. 179, Issue 1, Pages 1-23.

Beaman, K.R., K.G.S. Lilly, C.K. Gehring, P.J. Turk, and J.S. Moritz. 2012. Determining the efficacy of an exogenous enzyme cocktail post pelleting using broiler performance and metabolism. J. Appl. Poult. Res. 21:744-756.

Boney, J.W., A.E. Evans, and J.S. Moritz. 2013. The effect of feed form and experimental unit size on broiler performance research. Unpublished data. West Virginia University.

Brink, A.L. and A.E. Evans, P.J. Biggs, and J.S. Moritz. 2013. The effect of feed processing, protease efficacy, and bird sex on performance, yield, and digestibility of broiler chickens. Unpublished data. West Virginia University.

Corey, A.M., K.G.S. Wamsley, T.S. Winowiski, and J.S. Moritz. 2013. The effect of calcium lignosulfonate, mixer-added fat, and feed form on true amino acid digestibility and digesta viscosity. Vol 92 (Suppl. 1): 24.

Greenwood, M.W., P.M. Clark and R.S. Beyer. 2004. Effect of feed fines on level of broilers fed two concentrations of dietary lysine from 14 to 30 days of age. International Journal of Poultry Sci. 3 (7):446-449.

Jensen, L.S., G.O. Ranit, R.K. Wagstaff and J. McGinnis. 1965. Protein and lysine requirements of developing turkeys as influenced by pelleting. Poult. Sci. 44:1434-1441.

Lamp, A.E., and J.S. Moritz. 2013. The effects of pelleting and glucanase supplementation in barley based diets on feed manufacture, broiler performance, and gut viscosity. Poultry Sci. Vol 92 (Suppl. 1): 104.

Lilly, K.G.S., C. K. Gehring, K. R. Beaman, P. J. Turk, M. Sperow, and J. S. Moritz. 2011. Examining the relationship between pellet quality, broiler performance, and bird sex. J. Appl. Poult. Res. 20: 231-239.

Lilly, K.G.S. and J.S. Moritz, 2011. Resolving pellet quality issues and improving poult performance with the manufacture of commercial turkey diet formulations. Poultry Sci. Vol. 90 (Suppl. 1): 388.

Loar, R.E., K.G.S. Wamsley, A.Evans, J.S. Moritz, and A. Corzo. 2013. Effects of varying conditioning temperature and fat application on a broiler finisher diet. Poultry Sci. Vol 92 (Suppl. 1): 190. McKinney, L.J. and R.G. Teeter. 2004. Predicting effective caloric value of nonnutritive factors: I. Pellet quality and II. Prediction of consequential formulation dead zones. Poult. Sci. 83:1165-1174.

Shipe, K.J. and J.S. Moritz, 2011. Effect of feed manufacture techniques that vary feed exposure to pellet die heat and pressure on pellet quality and subsequent broiler lysine utilization. Poultry Sci. Vol. 90 (Suppl. 1): 389.

Wamsley, K.G.S. and J.S. Moritz. 2013. D1-42 yeast product inclusion and D42-118 feed form effects on large tom performance using feed produced at a commercial feed mill. Poult. Sci. 92 (E-suppl. 1): 220.

This paper was presented at the Arkansas Nutrition Conference September 3 – 5, 2013 at the Embassy Suites in Rogers, Arkansas, US- This annual educational event is sponsored by The Poultry Federation Feed Manufacturers Committee

Related topics

Authors:

Join to be able to comment.

Once you join Engormix, you will be able to participate in all content and forums.

* Required information

Would you like to discuss another topic? Create a new post to engage with experts in the community.

Create a post

.jpg&w=3840&q=75)