Introduction to the Single-Screw removal tool kit

Published: August 14, 2015

By: Jianbo Xie; Meng Zhang; Wei Liu; Liyang Liu

As an essential part of FAMSUN's extruder machinery, the single-screw extruder (for aquafeed, raw materials) is widely used in feed plants. The removal of screws has always been a problem in the operation of the extruder machinery. Every manufacturer may have its own removal tool kit, yet few can offer satisfactory solutions.

To develop new efficient removal tool kits, the following three factors should be taken into consideration:

To begin with, during peak production season, the machines have to stay operational as long as possible to cut cost rendered by downtime. To remove the screw head for instance, for lack of efficient methods, it usually takes 30 minutes to one or two days with nothing but temporary tools at hand. Considering the time consumed, it is of significant necessity to make improvements in the removing process to meet the production agenda.

Secondly, to lengthen the service life of the screw head, it is necessary to minimize the damage done to the screw head when it is being knocked off.

Besides, high degree of automation is necessary. So far some of FAMSUN's raw material extruders have been automatized, and these machines are more operation-friendly than they used to be. But simpler, faster removal tools are still needed to improve the competitiveness of FAMSUN's machinery.

1. The current FAMSUN removal tool kit

Currently, the removal tool kits available are for raw material extruders. As for TPH/PHY200, TPH260/PHY260 series extruders, the removal tool kit in use does not deliver satisfactory results.

Because of its structure, the tool can only remove the first section of the screw. Besides, specific leads of the screw are also required by current removal tools. And it also takes a lot of labor and time to manually turn the screw lever, especially when some of the screws haven't been removed for years. For single screw extruders for aquafeed, however, the aforementioned method does not work out. See the structure of the screw for aquafeed extruders:

2. The latest removal tool kit for single screw

Compared with earlier versions, the up-to-date removal tool kit can remove single screws of all types TPH200/260; PHY200/260; SJPS135/165/215/265), not just the first section of certain type of screws. The time needed to remove one section is less than 20 minutes.

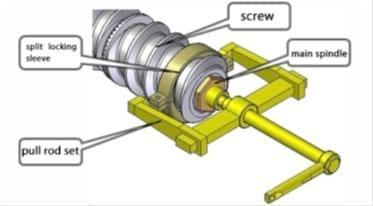

Its structure and operating principles are as follows:

Performance:

- Time spent in removing one section of screw: ≤20min

- Maximum thrust:30TX2

- Ability to remove each section of the screw: yes

- Number of operators: two

Structure:

- Double jack: to balance the force

- Hand pump: easy to handle

- Anti-deviation design: to make sure precision

- Extension rod: to make it easier to drive the whole screw out

- Mounting plate: the waist-shaped holes in the plate to make it easier to readjust the hold hoops in different positions;

- Spindle position-limit mechanism: to prevent the spindle from shifting positions when it is being knocked out by ejection mechanism. Patent No.:201320370871.3

Screw ejection mechanism

- The pair of jacks can be operated with the hand pump, their stroke synchronized by hand with less effort

- The mounting plate facilitates the fixation of the pair of jacks

- The waist-shaped holes make it easier to adjust the phase of the hold hoops in different positions

- The split locking sleeves are easier to be installed

- The anti-deviation design prevents the unsynchronized jack from getting stuck with the main spindle

- There are 20 extension rods to go with the machine to help remove the last screws

Position-limit mechanism

The position-limit mechanism is used to prevent the spindle from being damaged because of the friction caused by the spindle in the block and the main spindle (the current structure of the extruder only has the limit screw to bear backward thrust; without a limit screw to counter the forward force, the spindle can only take in little pulling force forward).

- The front bezel is composed of two half-type panels fixed in the inner wall of the spindle

- The backplate is composed of two quartered pieces fixed in the inner ring of the rear spindle

- The front bezel and the backplate are connected by a stopper bolt

- There are two M30 lock screws; each of them can bear an axial force of more than 30T

One thing to be noted: The position-limit device should be locked tight before this removal took kit is used.

Join to be able to comment.

Once you join Engormix, you will be able to participate in all content and forums.

* Required information

Would you like to discuss another topic? Create a new post to engage with experts in the community.

Create a post