Innovation and Application of Roller Liquid Addition and Spraying Technology for Pellet feed

Published: August 23, 2017

By: ZhengChang

Adding the proper amount of liquid raw material into the feed has become a convenient, flexible and effective way, which has been widely used in feed manufacturer. Through adding liquid, it can not only improve the feed’s energy level, but also can ensure the active ingredient in feeds to get fully utilized. Moreover, it can also improve the pellet feeds’ appearance quality and palatability in a large extent. Therefore, animals’ feed intake can be improved largely and this also increases the feed production, which allows the feeds’ quality to get market recognition.The process of adding liquid ingredient in feeds can be placed before granulation and after granulation. The addition amount before granulation generally does not exceed 4% of the output, otherwise it will cause problems such as loose particles after granulation. The largest amount of spray liquid can reach 8% after granulation. This can solve the impact issue which adding liquid brings to the feeds’ firmness, and it also be more suitable for extruded feeds’ production.

Drum Type Liquid Spraying Machine

Drum Type Liquid Spraying MachineFor the drum type liquid spraying machine which appeared earlier in the market, due to the existences of design problem, manufacturing problem, processing issue and the problem of use, there were always generating some issues after using a while. For example, oil spilling, deviation, noisy and some other problems, and these issues led to the operational difficulties.

Based on the actual situation of marketing and the application characters of drum type liquid spraying machine, ZHENG CHANG R&D Team started from the design problem, carried out comprehensive investigations, demonstrations and design analyses to it. The team also conducted a series of analyses aiming to solve the problems of weighing, oil deviation and oil spilling. In the end, the team designed a new drum type liquid spraying machine with high concentricity, good sealing degree, well-proportioned spraying and greatly adjustable spraying angle.

ZHENG CHANG drum type liquid spraying machine can spray grease, enzyme preparations, vitamin, organic acid, microorganism and other nutrients on the particle surface after pelletizing or the puffing. This machine can also realize the special recipe’s requirements from personalized pharmacists. It particularly applies to the recipes which need extremely small adding quantity but high uniformity.

ZHENG CHANG drum type liquid spraying machine can spray grease, enzyme preparations, vitamin, organic acid, microorganism and other nutrients on the particle surface after pelletizing or the puffing. This machine can also realize the special recipe’s requirements from personalized pharmacists. It particularly applies to the recipes which need extremely small adding quantity but high uniformity.

2017 Fuzhou, China Feed Industry Exhibition

Basic Operation Principle

Pellet feeds accept the spraying of trace elements in the elements adding scale through feed bin (The addition quantity can realize spraying from 8 pipelines at the same time, this can make recipe function quickly, efficiently and accurately). Then, through the belt conveyer’ smooth feeding, pellet feeds access into the revolving drum via draft tube, continue rolling and tossing. At the same time, the liquid supply system sprays liquid to the thrown particles through the nozzle according to the required spraying quantity, then the particles are discharged from the end of the drum.

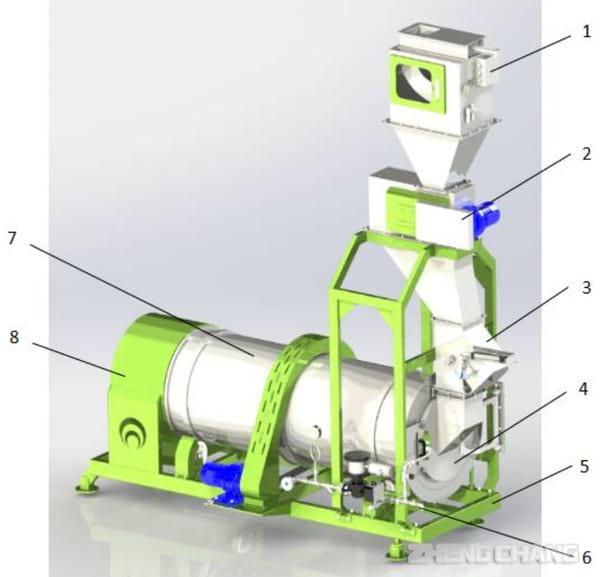

1. Microelements Adding Spraying Scale

2. Belt Conveyer

3. Pneumatic Three-way Damper

4. Inspection Hatch

5. Drum Base

6. Manifold Liquid Adding System

7. Customized Drum

8. Discharge Box

The Introduction of Use Function

First, the pellet feeds access into the trace elements’ adding scale through feed bin. Then, users can confirm the real spraying quantity of trace elements through trace elements’ weighing adding scale and adding proportion. In this process, users can add many different kinds of trace elements into it, such as, enzymes, vitamin, flavours, microbial preparation, growth promoter and so on. The adding proportion is 0.01%~3%.

The particle of trace elements which are sprayed completely will access to the belt type conveyer through artesian way. The belt type conveyer was drove by variable frequency motor, the user can adjust transmission frequency according to material level of feed bin, convey pellet feed into the roller through diversion pipe.

The roller was rotated by one gear motor through belt driving and it was supported by two pairs of wheel. In the front, there is one stopper which was used to stop the wheel from gliding. The roller was put obliquely towards the exit, the angle can adjust (generally, it adjust 5 to 6° at the beginning). In the middle, there is a spraying tube, and there is a pressurized air atomizing nozzle on it. In the inner wall of roller, there is a reversing plate with special angle. With the rotation of roller, it can toss the materials, let the particle accept the liquid spray during the process of tossing. Also, in this process, user can spray grease, molasses and many other liquid. The adding proportion can reach at 8% for maximum. The pellet feed which after spraying can be transported to the discharging box through the rotation of tilted roller and then access to the follow-up machines.

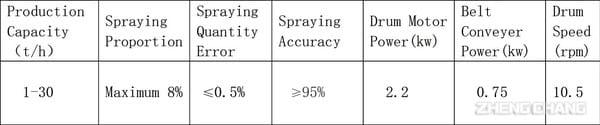

The table upwards is technical parameter

Main Performance Characteristics

1. The new type of roller has been systematization, it has large capacity utilization, and it can satisfy configuration requirements in different quantities, such as from 1 ton to 30 tons per hour.

1. The new type of roller has been systematization, it has large capacity utilization, and it can satisfy configuration requirements in different quantities, such as from 1 ton to 30 tons per hour.

2. Drum-type spraying adopts reversing plate from special angles and air atomizing burner. The particle of liquid spraying is very small so that it can contact completely with the surface of particle, the uniformity of spraying can reach more than 95%.

3. Its one-piece installation structure does not need to take apart for shipping and it also do not need to field assembly. Its fool-style operation allows people to use it in-place.

4. The inclination’s angle of roller can adjust. The user can make adjust according to materials’ different flow angles.

5. Its large open structure make it is convenient, easy and efficient to clean the roller.

6. Its sealing form will has no leak of dust and grease, which make the environment very clean and clear.

7. The computer can automatic control adding quantity completely, this makes the measurement more concise, which can realize no deviation in recipe function.

8. Double adding type let the pelletized products has comprehensive and balanced nutrition. The manager and formulator can worry-saving, set their mind and be relieved.

Related topics

Join to be able to comment.

Once you join Engormix, you will be able to participate in all content and forums.

* Required information

Would you like to discuss another topic? Create a new post to engage with experts in the community.

Create a post