CoolexTM – a crucial step towards achieving the perfect pellet

Published: June 8, 2015

Source : Bühler

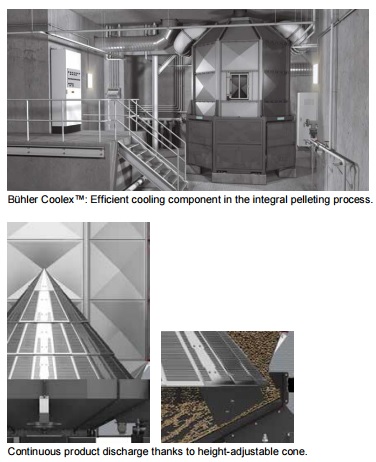

Decades of experience prove it: Optimal pellets cannot be produced using single machines or systems alone, but only on the basis of a seamlessly matched process chain – from cleaning and grinding to mixing, conditioning, pelleting, and cooling. And proper pellet cooling is one of the crucial process steps in the production of high-quality end products that has up to now not been adequately optimized. The new Bühler CoolexTM pellet cooler sets new standards in the feed manufacturing industry and will be presented for the very first time to the specialist public at VICTAM 2015 in Cologne.

Integral pelleting processes require individual system components that can be fully integrated in the overall production process. With its new CoolexTM cooler, Bühler offers feed producers not only efficient cooling and optimal hygiene, but also sets new standards in this area. This is the firm conviction of Stefan Hoh, Product Manager Feed at Bühler: “Efficient cooling of the still hot pellets is a process step that should not be neglected if high-quality end products are to be obtained. Proper cooling of feed pellets in the pelleting process chain means very much more than just to reduce the pellet temperature.

With our new perfectly integration-enabled CoolexTM cooling component, we support our customers in their efforts to increase their product quality and hygiene while at the same time cutting their costs.”

Efficient cooling and continuous product discharge

Efficient cooling and continuous product dischargeBühler CoolexTM is a breed apart by its visual appearance alone. Its innovative design based on the countercurrent principle and its conical product layer and octagonal geometry enable many important process steps to be optimized, ensuring a consistently high product quality of the pellets. With its specific air volume of merely 10 to 16 m3 per minute and metric ton, CoolexTM has a higher energy efficiency than many conventional coolers.

“But energy efficiency is only one aspect of our new CoolexTM that has a positive impact on feed producers’ margins,” explains Stefan Hoh. Thanks to the reliable reproducibility of the product quality, feed manufacturers can stretch the moisture content of their end product to the legally allowed limits and reduce their raw material consumption. This uniform cooling action enables the moisture content variance to be reduced to about half the value of conventional coolers, allowing margins to be perceptibly increased yet again.

Another unbeatable benefit that Bühler mentions for its new CoolexTM is the adjustability of the continuous product discharge rate, which ensures optimal throughputs and retention times. “Moreover, a uniform discharge rate enables smaller downstream system components such as conveyors or pellet crumblers to be used,” explains Stefan Hoh. This cuts the capital investment and operating costs of downstream systems or allows higher throughput capacities to be achieved in a smaller space.

More hygiene and less costs

Bühler CoolexTM is the first pellet cooler to be provided with several service doors and up to four integrated inspection windows. This makes cleaning of the cooler very much easier and significantly reduces product deposits, greatly diminishing the contamination risk and the risk of costly and imageimpairing recall campaigns. But the smart design of this cooler offers even more benefits, for it needs much smaller fans. This cuts energy consumption in comparison to other countercurrent cooler designs by as much as 10%. CoolexTM has a minimum number of wear parts and no hydraulic components at all. Elimination of the need for wear-prone ball bearings on the discharge grid and the use of durable, cost-effective air cushions that can be exchanged in a mere 60 minutes not only minimizes downtimes, but also ensures dependable, low-maintenance operation.

Easy installation and integration

With its CoolexTM, Bühler offers feed producers a highly efficient component that can be readily integrated in any production system. All parts can easily be brought to their places through standard doors. The installation costs are as low as the downtimes of the system. In addition, Bühler offers a number of upgrade options meeting any requirement. At present, four packages are available, and more are already in the planning stage. “CoolexTM is yet another step on the way to the perfect pellet,” says Stefan Hoh confidently. “For achieving completely integrated processes and thus our customers’ success.”

Source

Bühler Join to be able to comment.

Once you join Engormix, you will be able to participate in all content and forums.

* Required information

Would you like to discuss another topic? Create a new post to engage with experts in the community.

Create a postEngormix

10 de junio de 2015

Engormix was present at the launch of the Bühler Coolex with Frank Nehlig and Stefan Hoh.

|

|