Market Pig Transport

Published: June 7, 2013

By: John McGlone1; Anna Johnson2; Avi Sapkota1; Rebecca Kephart2 (1Texas Tech University; 2Iowa State University)

Introduction

Transportation is a necessary part of modern U.S.A. pig production. Over 100 million U.S.A. pigs are transported 2 or 3 times from birth to market (USDA, 2005). Pigs are most often transported at weaning from a farrowing barn to a nursery or wean to finish barn. Those taken to a nursery are transported to a finishing site (5 to 9 weeks later). Finally pigs are transported from the finishing site to the processing plant. For these two or three transport experiences, pigs become stressed to various degrees and these have been termed "transport losses." Transport losses refer to pigs that become non-ambulatory or die at any stage of the marketing process. Examples of transport losses in market weight pigs include; "non-ambulatory pigs" (fatigued [NANI] and injured [NAI]), "dead on arrival" (DOA), "dead in yard" (DIY) and "dead in pen" (DIP). A thorough review of the definitions, incidence and economical impacts of these transport losses have been assembled by Ritter et al. (2009). The main problems with transport are when pigs are DOA, NANI or NAI. Total dead and down (D&D) may approach 1% on some farms and plants. The rate of DOA in the USA is currently about 0.17% and the rate of NAI and NANI is about twice that. If the national average of pig losses is about 0.5%, this represents pig losses of over 500,000/year. Improving pig transport has direct animal welfare and economic benefits.

For pigs, the transportation process is a combination of unfamiliar or novel experiences that could be perceived as stressful. If the pig is not able to cope with these sequential and additive stressors, we will see increased losses through elevated mortality, morbidity and decreased product quality. Transport losses are multi-factorial and involve people, pig, facility design, management, transportation, processing plant, and environmental factors (Anderson et al., 2002; Ellis et al., 2003; Ellis and Ritter, 2005; Ritter et al., 2009a). By identifying potentially additive factors within the marketing stages that may be potential stressors to the pig, we may attempt to reduce stressors placed upon the pig and subsequently reduce transport losses.

Transport by itself does not have to be negative and the vast majority of pigs make it through transport with no adverse reactions. Consider an experienced dog that jumps into a car to go for a ride at any opportunity. That animal is not stressed by that transport experience. But consider, in sharp contrast, a pig that is taken from its mother and placed in a strange environment (like a livestock trailer) that is cold (or hot) with no food or water. Then it rattles and vibrates and moves in a manner that causes motion sickness.

However, there are aspects of transport that some individual pigs are unable to cope with as well as their counterparts. A few factors are as follows:

- The pig's previous experiences (or lack of experience)

- The novelty of the marketing / transport experience

- Degree of human interaction before transport (ex., in finishing pens)

- Temperature and relative humidity extremes

- Wind currents

- Bright sunlight if they were raised inside a building

- Footing and flooring

- Ramps with an up or down slope

- Vibrations and movements that may induce motion sickness

- Fencing materials that might be foreign or distracting

Let us speculate and make an educated guess about the market transport experience. Imagine a market pig that has been in a finishing pen for 16 weeks. It was ~8 weeks old when it arrived. It lives with 24 others pigs. One died. Every day someone walks by the aisle. Mostly the pig does not pay attention. Once or twice a week, someone walks in the pen which causes a stir. The pig may have to move to avoid the person. If the human stops for more than a minute, the pig may come investigate and chew the humans pant leg and boots, but otherwise it has not touched or been touched by a person since it can remember. Then one day, someone comes into this stable environment and moves the pig out of the pen, perhaps with pigs it has never met before, down the aisle, outside (where it is a different temperature), up a ramp and onto a strange surface (aluminum flooring). The pig experiences a stress associated with novelty and unfamiliarity, and then if it experiences rough handling, hot or cold temperatures and/or slippery floors – the stress is likely to be additive (Broom and Johnson, 1993). Next transportation, truck types and trailers used to transport market pigs vary around the world. Shown in Figure 1 are four trucks/trailers. The U.S.A. is intermediate in the intricacy of transport equipment (between South America & Asia vs. Europe). The trucks used in Colombia today are much like those common in the U.S.A. 30+ years ago.

Figure 1: Pig transport in modern times. A is a modern U.S.A. pig trailer, partially boarded for cool weather. B is a truck from Colombia which demonstrates not only how pigs are transported there, but how they were transported in the U.S.A. 30 years ago. C is a 4-deck pig for finishing pigs in China. D is a modern European trailer with ventilation controls.

In today's system, this multi-component experience, some components are unavoidable, like air temperature and novelty. Other components for example, how the trailer is prepared (i.e. levels of bedding used, boarding implemented and on board misting systems) and how pigs are handled, are under the control of people. For those factors with which we have less control, we can intervene. And just how we intervene is chronicled in the Trucker Quality Assurance? (TQA) program designed by the National Pork Board (http://www.pork.org/Certification/10/ tqa.aspx). The TQA program is designed to improve the welfare of pigs and to improve the profitability of pig transport. Some materials in the TQA program are based on professional judgment which we know is fallible. Scientific investigation can help us refine transport protocols so that pig welfare is less compromised.

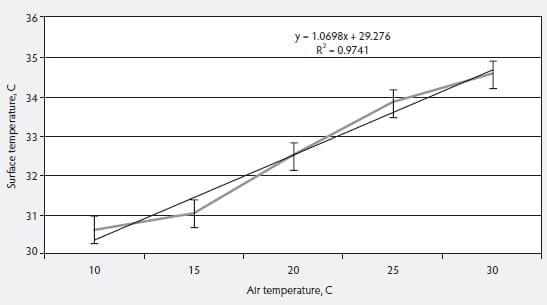

Hot weather increases DOA

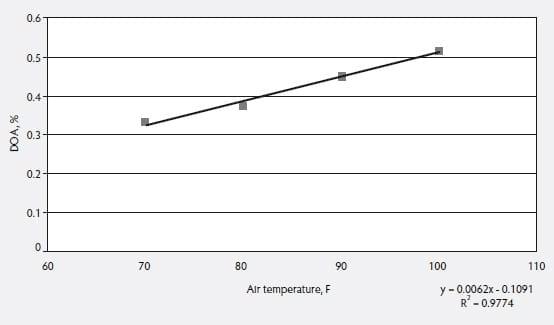

It does not matter what the outside air temperature is on a given day – if pigs get too hot, they will die. Pig surface temperature raises in proportion to outside air temperature much like a reptile. Note in Figure 3 the linear rise in pig surface temperature with a rise in outside air temperature. These data were collected on over hundreds of trailer loads of pigs in the Midwestern USA. When outside air temperature rises, pig surface temperature gets higher and the DOA goes up. It is really that simple.

What intervention might help? First we have to minimize handling during very warm temperatures (this is considered impossible by many people). Second, we need to have the most gently handling that is possible during warm weather (over 70°F). Third, we must not stop the truck on its trip (it heats up), not have any wait time at the plant unless the trailers are under a large fan and shaded and unloading should be done humanely but efficiently. Fourth, we need be sure we do not overcrowd the trailer (Fitzgerald et al, 2009). Apart from these best management factors, what can we do?

The three tools we have for USA trailers are to vary the boarding, bedding, and application of water (misting). These cool pigs (or keep them warm) by air flow (or blocking air flow), insulation between the pig and the trailer, and evaporative cooling. In warm weather (over 70°F or 21°C), the boarding (or plugs) are all open. Many plants enforce this boarding rule and truckers are well aware of the need for as much ventilation as possible in warm weather. The problem with warm weather is when the truck and trailer stop because the trailer heats up in a linear fashion starting about 2°F above outside air temperature.

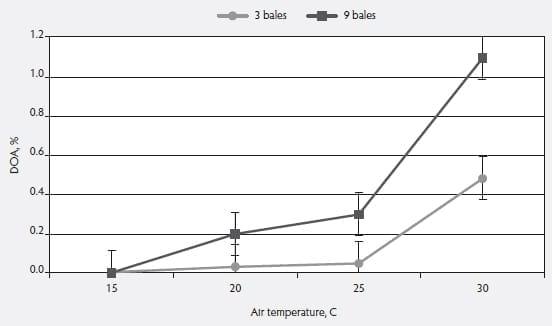

Bedding can be adjusted in warm weather, but how much is needed? We conducted a study in 2011 that examined 772 trailers. In the warm months of June and July we examined 254 trailers with 43,180 pigs. We had researchers at the farm sites and plants to measure pig handling, behavior and D&D rates. Drivers applied between 3 and 9 bales of wood chips (or shavings)/trailer over June and July.

The DOA rates responded to both bedding and air temperature in a significant and additive manner. That is, more bedding caused higher DOA rates and warmer air temperatures caused higher DOA rates. When added together, excessive bedding (9 bales) is quite deadly in warm weather (Figure 6). In warm weather, it is advisable to use a minimum amount of bedding.

Cold weather increases NANI pigs

Cold weather increases the rate of NANI pigs during transport. That is not to say the DOA rates cannot rise in cold weather. When the air temperature is cold, and trucks are highly boarded, and they sit still, it can get warm in the trailer which can cause DOA. But in most cases, pigs do not experience heat stress in cold weather. Rather, the risk to pigs during cool and cold weather is for NANI pigs.

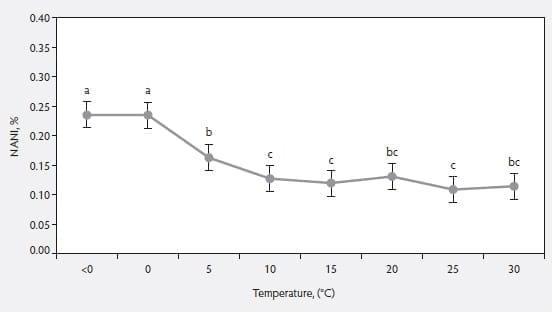

Sutherland et al. (2009) sampled the rates of D&D for 2 million pigs over a one-year period. In cold and cool weather (temperatures less than 41 F (5 C), the rates of NANI pigs increased (Figure 7).

Figure 2: Fatigued (NANI) pigs.

Figure 3: Changes in pig surface temperature in relation to outside air temperature. These data were collected on hundreds of pigs during spring and summer seasons.

Figure 4: Linear increase in DOA rates above 70°F (21°C). From Sutherland et al., 2009 who sampled over 2 million pigs at a commercial processing plant over a year.

Figure 5: Bedding in trailers with 1 or 6 bales/deck the bedding does not quite cover the trailer floor. 1 bale of wood chips is 50lb (23kg) and covers about 7ft3 (~105cm3).

Figure 6: The effects of bedding level and air temperature were additive for % DOA. More pigs died with more bedding. More pigs died in transport with the warmer air temperatures. The effects added. The DOA rates were over 1% of pigs whe the air temperature was over 30°C (86°F) and 9 bales were used per trailer.

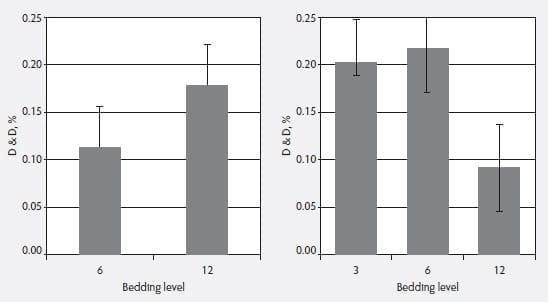

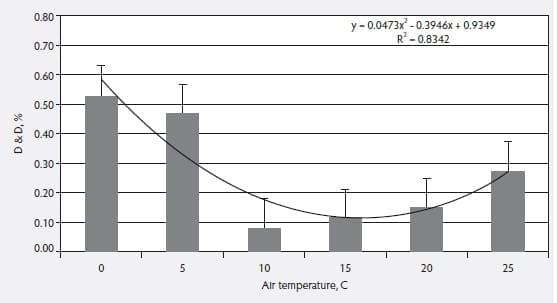

In our recent work, we used 6 or 12 bales/trailer in winter and 3, 6 or 13 bales in winter and spring to evaluate pig behavior, handling, and transport losses. We found that no matter the bedding level used, pig losses did not change (Figure 8). This means adding additional bedding does not change pig losses in cool and cold weather. We still found that cool weather (below 50°F or 10°C) caused an increase in D&D, primarily NANI pigs. DOA was not changed with cool and cold weather. Producers, transporters and plants can save money and not compromise pig welfare by not over-using bedding in cool and cold weather.

Other major factors in transport loss

Particular farms may have issues with NANI pigs. Apart from cold temperatures, two other major factors (and some suspected others) have a large effect on the rate of NANI pigs: travel time and handling intensity.

Sutherland et al. (2009) examined the effect of traveling time on the rate of NANI pigs in their sample of over 2 million pigs. They found the slope of NANI pigs over travel time was negative and had an r-square of 0.93. At less than an hour from the plant, NANIs registered were over 0.3% while at 10+ hours the NANI rate was nearly 0%, and a linear decline in percent NANI as travel time increased. NANIs are thought to be the result of a metabolic challenge that results in a fatigued pig. After their novel experiences loading onto a trailer, the pigs have elevated heart rate and stress hormones. As the trip progresses they settle down and show few physiological signs of stress. It takes them up to 10 hours to get over the stress of loading. If they travel that long, then the pigs can more easily handle the stress of unloading (Pérez et al, 2002).

Handling intensity is the level of handling the pigs experience from very calm and smooth (score of 1) to the use of excessive force in moving pigs (score of 5). We found that 9.8% of our 467 trailers directly observed in 2011 showed this extreme handling. At unloading, the plants are audited and may be penalized if more that 25% of pigs vocalize. The D&D rates may reflect this lack of attention to pig handling and overall welfare on some farms. We observed that on farms with the best handling (scores of 1) had the lowest rate of (zero D&D) D&D pigs compared with scores of 2 to 5 (averaged 0.22 ± 0.10% D&D pigs; r2 between handling intensity and D&D was 0.70). Pig handling is industry issue that must be continually addressed.

In other than winter months, barrows have more NANI pigs than do gilts (Sutherland et al., 2009) and overall, barrows have about 55% more D&D than gilts (P < 0.05). The sex effect was more pronounced in straight-deck trailers than pot bellied trailers. If the wait time at the plant is too long, the rate of DOAs goes up (Sutherland et al., 2009). When the wait time exceeded 60 minutes at the plant, the DOA rate increased 50% compared with shorter plant wait times.

Figure 7: Rates of Non-ambulatory, non-injured pigs in cool and cold weather. From Sutherland et al., 2009. In this 2-million-pig sample, NANI % increased when air temperature was below 10°C (50°F).

Figure 8: Effects of bedding level on total dead and down rates (D&D). Left graph represents data collected in winter and the right graph represents data collected in the spring. In both seasons, bedding level did not significantly change pig losses (DOA, NANI, or D&D).

Figure 9: In springtime, the rates of dead and down pigs (D&D) increased when the air temperature was below 10°C (50°F). This increase was not impacted by changing the bedding levels.

On-going work

Our scientific investigations of transport losses are continuing. This year (2012) we are investigating the correct amount of boarding (spring and fall) and misting (summer). Keep posted for updates.

References

1. Anderson, D. B., D. J. Ivers, M. E. Benjamin, H. W. Gonyou, D. J. Jones, K. D. Miller, R. K. McGuffey, T. A. Armstrong, D. H. Mowrey, L. F. Richardson, R. Seneriz, J. R. Wagner, L. E. Watkins, A. G. Zimmermann. 2002. Physiological responses of market hogs to different handling practices. p. 399 in Proc. of the Am. Assoc. Swine Vet., Kansas City, MO.

2. Broom, D.M., K.G. Johnson. 1993. Stress and Animal Welfare. 1st ed. Chapman & Hall Animal Behaviour Series. New York, NY.

3. Ellis, M., F. McKeith, D. Hamilton, T. Bertol, M. Ritter. 2003. "Analysis of the current situation: What do downers cost the industry and what can we do about it?" p. 1 in Proc. of the 4th Am. Meat Sci. Assoc. Pork Quality Symp., Columbia, MO.

4. Ellis, M., M. J. Ritter. 2005. Impact of animal handling and transportation conditions on losses of slaughter weight swine during transport. 36th Ann. Mtg. Amer. Assoc. Swine Vet. p. 199– 202.

5. Fitzgerald, R.F., K.J. Stalder, J.O. Matthews, C.M. Schultz Kaster, A.K. Johnson. 2009. Factors associated with fatigued, injured, and dead pig frequency during transport and lairage at a commercial abattoir. J. Anim. Sci. 87: 1156– 1166.

6. Laboratory of Animal Behavior, Physiology and Welfare. 2012. Texas Tech University. Pig Transport Site. http:// www. depts.ttu.edu/animalwelfare/Research/Transport/index.php

7. Pérez, M. P., J. Palacio, M. P. Santolaria, M. C. AceÑa, G. ChacÓn, M. GascÓn, J. H. Calvo, P. Zaragoza, J. A. Beltran, S. García-Belenguer. 2002. Effect of transport time on welfare and meat quality in pigs. Meat Science. 61: 425–433.

8. Ritter, M. J., M. Ellis, N. L. Berry, S. E. Curtis, L. Anil, E. Berg, M. Benjamin, C. Dewey, B. Driessen, P. DuBois, J.D. Hill, J.N. Marchant-Forde, P. Matzat, J. McGlone, P. Mormede, T. Moyer, K. Pfalzgraf, J. Salak-Johnson, M. Siemens, J. Sterle, C. Stull, T. Whiting, B. Wolter, S.R. Niekamp, A.K. Johnson. 2009a. REVIEW: Transport losses in market weight pigs: I. A review of definition, incidence, and economic impact. Prof. Anim. Sci. 25: 404–414

9. Sutherland, M. A., A. McDonald, J. J. McGlone. 2009. Effects of variations in the environment, length of journey and type of trailer on the mortality and morbidity of pigs being transported to slaughter.

10. USDA. 2005. Commercial Livestock Slaughter by Months, Iowa and U.S.. http://www.nass. usda.gov/Statistics_by_ State/Iowa/Publications/Annual_Statistical_Bulletin/ 2006/06_99.pdf. Accessed Feb. 9 2012.

Acknowledgments

This work was supported by Texas Tech University, Iowa State University, the National Pork Board, Elanco Animal Health, a very large number of producers, and several packing plants that wish to remain anonymous. We thank the many faculty, graduate and undergraduate students that helped in data collection including: Dr. Art Coquelin, Dr. Kim Guay, Garrett Thomson, Mitch Akins, Tucker Williams, Derek Tomison, David Smith. Portions of this paper appear on the Texas Tech University web site and are available for educational purposes without copyright restrictions, although citing the source would be appreciated: http:// www.depts.ttu.edu/animalwelfare/ Research/Transport/index.php.

This paper was presented at the Allen D. Leman Swine Conference, held Sept. 15-18 at the St. Paul River Center in St. Paul, Minnesota. Published by Veterinary Continuing Education, Volume 39 2012. Engormix thanks the university and the author for this huge contribution.

The University of Minnesota, Allen D. Leman Swine Conference is an annual educational event for the global swine industry. It is internationally acclaimed for bringing science-driven solutions to the complex challenges facing the industry. Each year hundreds of participants from over 20 countries attend the Leman Swine Conference held in St. Paul, Minnesota, USA. Major players in swine production, animal health management, and marketing from around the world exhibit their products and services.

To see more about Allen D. Leman Swine Conference 2013 edition, please click here

Related topics

Authors:

Join to be able to comment.

Once you join Engormix, you will be able to participate in all content and forums.

* Required information

Would you like to discuss another topic? Create a new post to engage with experts in the community.

Create a post

.jpg&w=3840&q=75)