INTRODUCTION

In ancient times, mankind survived with food from daily hunting. As human being accumulates experiences and knowledge about nature, agriculture became a major way of obtaining food. Agricultural activity also allowed us to have stable food supply and this was one of important reasons for the increase in human population and cultural flourish. As entering modern society, growth of human population accelerated as so demands for food. Limited space and resources with fast growing demands for food has pushed agriculturists to improve efficiency of food production through agriculture. Animal agriculture (or livestock production) is an important part of agriculture producing meat and fat. Pork production takes a key role providing over 42% of global meat consumption. This article is focused to discuss the roles of bio-fermentation technology on improving productivity of pork production in the area of nutrition based on the author´s own research experiences.

SWINE NUTRITION AND BIOTECHNOLOGY

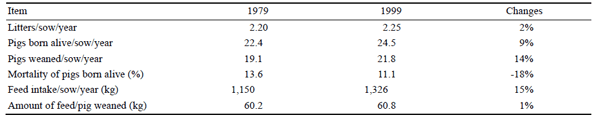

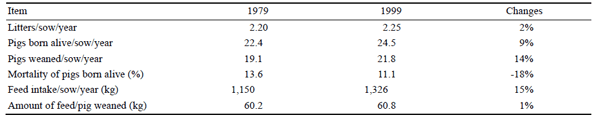

We can´t ignore that continuous genetic selection has made great contribution to animal agriculture by improving genetic potentials of maximal productivity. Scientific advances in nutrition, then, allowed expressing these genetic potentials to maximize productivity of livestock. It is amazing to see the improvement of productivity of pork production during the 20-40 years. The author had a chance to compare few economically important traits of pigs (especially for sows) between 1979 and 1999 (Kim, 1999). During the past 20 years, performance of sows has been improved dramatically. As examples, litter size of sows has increased by 9% whereas litter mortality has reduced by 18% (Table 1).

Table 1. Major changes in sow performance between 1979 and 1999. Adapted from Kim (1999)

It is not difficult to see the evidences showing that biotechnology was a key driving factor for the great improvement in the efficiency of pork production. One can easily think genetic engineering as a main theme of biotechnology. However, genetic engineering is only a portion of biotechnology. United Nations Convention on Biological Diversity defines biotechnology as "Any technological application that uses biological systems, dead organisms, or derivatives thereof, to make or modify products or processes for specific use". Biotechnology indeed includes a broad range of applications including bioengineering, bio-remediation, gene therapy, genetic selection, bio-degradation, cloning, bio-fermentation, etc. Among these, we can find many evidences that pork production has much been benefited from application of bio-fermentation technology in preparing feed and feed additives. In the next sections, few examples of successful application of bio-fermentation technology in swine nutrition are described based on the author´s own research experiences.

SUPPLEMENTAL AMINO ACIDS

It is early 1960s when an amino acid, mono-sodium glutamate, was produced in a large scale using biofermentation technology to be used for food application. Soon after, similar bio-fermentation technology was applied to produce feed grade supplemental amino acids. Supplemental amino acids are produced by liquid state fermentation. Briefly, sugars from sugar cane are extracted and used as a substrate for fermentation by microorganisms specifically selected for synthesizing targeting amino acids. After these microorganisms excrete targeting amino acids to broth, drying process and filtration are followed to obtain crystalline amino acids. Good examples of supplemental amino acids that can be produced in large scales are Llysine HCl, L-threonine, and L-tryptophan which are, in fact, three key limiting essential amino acids for swine. In recent years, feed grade supplemental L-glutamine and Lvaline are also introduced by a company leading this area. L-arginine HCl is another good example of supplemental amino acid for its unique function in an animal body that is also produced by bio-fermentation. Production efficiency of supplemental amino acids through bio-fermentation has been improved significantly due to advances in biotechnology. Currently production efficiency of L-lysine reaches over 50%.

L-lysine HCl is the first feed grade supplemental amino acid that is produced in a large scale by bio-fermentation which is soon after production of mono-sodium glutamate for food application. It was early 1960s when feed grade Llysine HCl was mass-produced first time in Japan. Since then L-lysine has well been used as the first limiting essential amino acid in swine feed. It may be 1950 when the first research paper about the requirement of lysine for swine published in a scientific journal (Brinegar et al., 1950). Several years later, Meade and Teter published a paper demonstrating the use of supplemental L-lysine HCl in swine diets to determine lysine requirement (Meade and Teter, 1956). Use of supplemental L-lysine in animal feed has continuously been increased and the current annual global use of L-lysine is near 900,000 ton. As research on swine nutrition advanced, second and third limiting essential amino acids were identified as L-threonine and Ltryptophan (Shelton et al., 1951; Beeson et al., 1953), and a large scale production of L-threonine and L-tryptophan by bio-fermentation began 1980s. Currently global use of Lthreonine and L-tryptophan are 65,000 and 1,900 ton, respectively and their usage continuously increases.

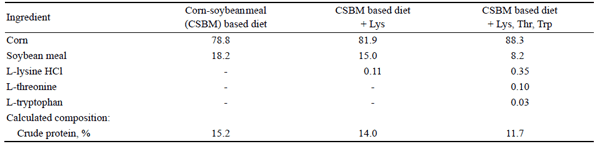

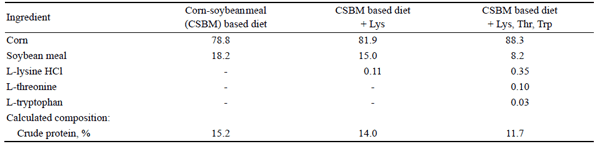

Production efficiency of lean pork has been maximized as nutritionists can formulate swine feed matching requirements of these limiting essential amino acids and reducing crude protein contents. It can be formulated to include 11.7% crude protein with the use of L-lysine, Lthreonine, and L-tryptophan which would provide an equal nutritional value of feed containing 15.2% crude protein without supplemental amino acids (Table 2).

Recently, a large scale production of feed grade L-valine has been initiated using bio-fermentation technology. Use of L-valine, which is often 4th or 5th limiting essential amino acids for swine, allows nutritionists to further reduce crude protein content in the feed without affecting growth performance of pigs. When these four feed grade amino acids are used in swine feed, 1% value of crude protein content can be further reduced. Currently feed grade Lvaline is only marketed in European Union, however, the use of L-valine will soon be extended to Americas and Asian countries. Development of new feed grade L-valine allowed nutritionists to formulate swine feed with high accuracy for maximal lean growth as well as that is environmentally friendly by reducing contents of excess amino acids in the diets over the requirements.

Table 2. Typical diet formula and compositions for swine with or without supplemental amino acids

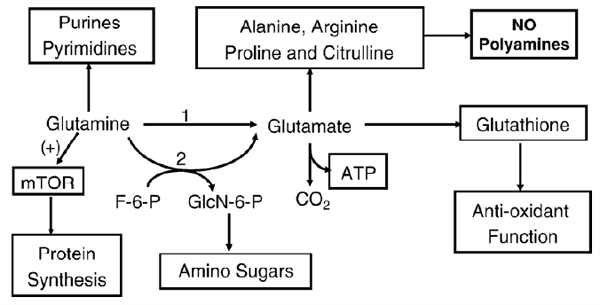

Another feed grade amino acid that is recently development by bio-fermentation is L-glutamine. Concept of applying L-glutamine in swine feed is somewhat different from the use of previous four limiting amino acids. L-glutamine is known as a non-essential amino acid that is not a limiting amino acid for swine. However, recent research clearly indicates specific function of L-glutamine other than being used for protein synthesis in an animal body. It is demonstrated that L-glutamine is a major energy substrate and an essential precursor of Nacetylglucosamine- 6-phosphate for proliferation and growth of enterocytes and for prevention of intestinal atrophy (Figure 1; Kim et al., 2007a; Wu et al., 2007). L-glutamine is essential for development of gut function especially for newly weaned young piglets that are under stressful condition due to new environment and diet changes. It is also suggested that pigs under chronic or acute stress with immune depression can be benefitted by supplemental Lglutamine as immune cells use L-glutamine as a major energy source.

Figure 1. Role of L-glutamine in porcine enterocytes. Adapted from Kim et al. (2006) and Wu et al. (2007).

Thus application of feed grade L-glutamine includes newly weaned piglet as well as pigs under stressful environment. Currently, feed grade L-glutamine is available only in South America as well as selected countries in Asia. However, feed grade L-glutamine will soon be available in North America, European Union and remaining Asian countries.

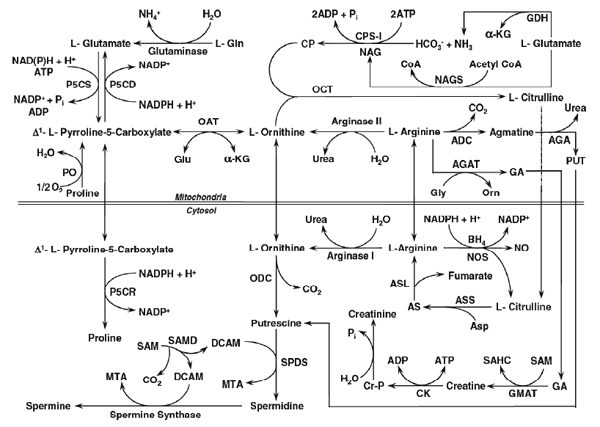

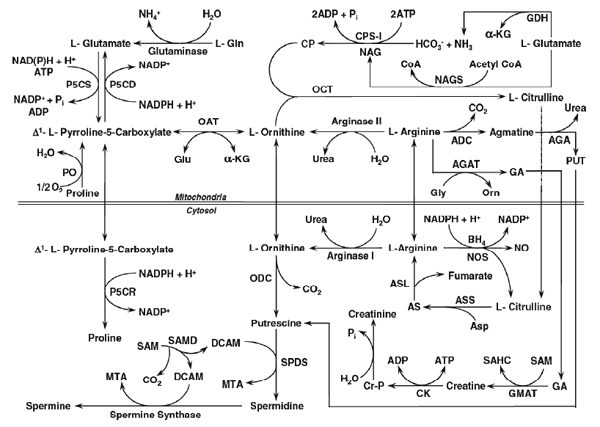

L-arginine is another important example of an amino acid that has great potential to be used in swine feed even though a large scale feed grade production has not occurred yet. There are many research papers showing unique functions of L-arginine in an animal body including humans (Figure 2; Wu et al., 2004; 2007; 2009).

Figure 2. Arginine metabolism in mammals. Adapted from Wu et al. (2008).

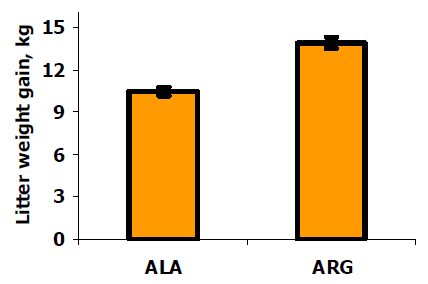

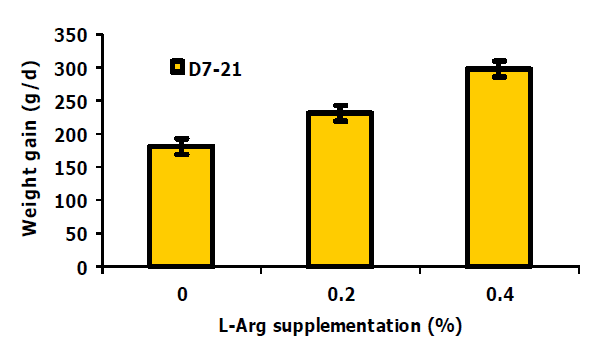

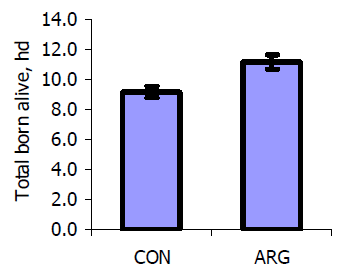

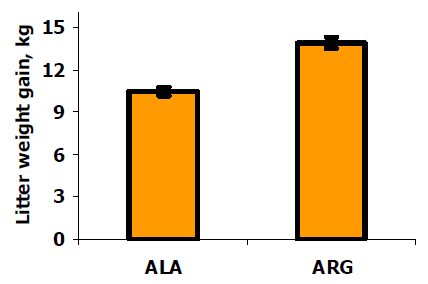

Briefly, L-arginine can be used by endothelial cells lining blood vessels which possess an enzyme called nitric oxide synthase converting L-arginine to citrulline releasing nitric oxide. Production of nitric oxide causes conversion of cellular GTP to cGMP which will cause vasodilatation with increase blood flow. In the mean time, L-arginine can also be converted to orinithine which will in turn metabolized to a group of polyamines including spermine and spermidine. Polyamine is known as a key components used for angiogenesis and cell proliferation. A recent study showed that dietary supplementation of L-arginine to milk replacer improved growth of newly born piglets (Figure 3; Kim and Wu, 2004). Sows are also benefitted by dietary supplementation of L-arginine. Improved blood flow to placenta and mammary gland increased nutrient supply to fetuses for growth and to mammary gland for milk production. Sows with supplemental L-arginine had reduced number of dead born piglets and increased milk production during early stage of lactation (Figure 4 and Figure 5; Mateo et al., 2007; 2008).

ENZYMES

Rapid increase in the cost of feed ingredients caused such a big obstacle to swine producers. Shortage of good quality feed grains pushed swine producers to include grain sources that are not in a best quality with indigestible nutrients and with potential anti-nutritional factors and mycotoxins. This caused decrease in production efficiency due to reduced utilization of nutrients in the feed by pigs. Use of exogenous microbial enzymes has greatly been increased in feeding swine. Most of exogenous enzymes are produced by bio-fermentation to help digestion of specific nutrients or compounds in the feed or feed grains. Thus specific enzymes can be supplemented to a diet with specific ingredients with potential problems. One of popular examples is the use of phytase to hydrolyze phytic acid structure releasing phosphorus as well as other minerals. There are several types of phytase products with distinct characteristics depending on the origin of microorganisms used for bio-fermentation (Kim and Baker, 2003). Use of phytase in swine feed improved utilization of phosphorus in feed grains reducing the amount of phosphorus in phytic acid excreted in manure. Phytase would be one of largely used exogenous microbial enzymes in animal feed.

Figure 3. Growth of nursing piglets (d 7-21) fed milk replacer with or without L-arginine. Adapted from Kim and Wu (2004).

Figure 4. Number of total born alive in a litter of sows fed gestation diets with or without L-arginine supplementation (1% as L-arginine HCl). Adapted from Mateo et al. (2007).

Figure 5. Weight gain (d 1-7) of a litter from sows fed lactation diets with or without L-arginine supplementation (1% as Larginine HCl). Adapted from Mateo et al. (2008).

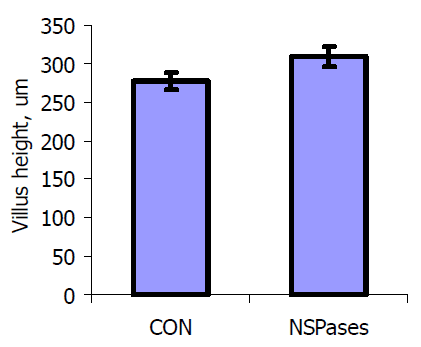

There are another types of exogenous enzymes that became popular. Carbohydrases or more often called NSPases (non-starch polysaccharidases) helps efficiency of energy utilization of feed grains by pigs. Application of exogenous NSPases should consider types of feed grains used in the diet because types of NSPs are different depending on feed ingredients (Kim and Baker, 2003). For corn-soybean meal based feed that are most widely used in Americas and Asian countries, types of NSPs that interfere energy digestibility are galactosides, mannosides, soybean oligosaccharides (raffinose, stachyose, and verbascose). These NSPs are also shown to reduce protein digestibility as they interfere access of proteases to substrates due to complex structure of NSPs that are bound to proteins. Use of NSPases targets elimination of these anti-nutritional NSPs in swine diets. Research by Kim et al. (2003) showed that exogenous NSPases improved digestibilities of energy as well as protein in corn-soybean meal based diets when fed to nursery pigs. These pigs with exogenous NSPases also had reduced damage to villus structure compared to pigs fed diets without NSPases (Figure 6; Kim et al., 2003). This may due to beneficial effects of these NSPases successfully eliminating raffinose family NSP known as anti-nutritional factors.

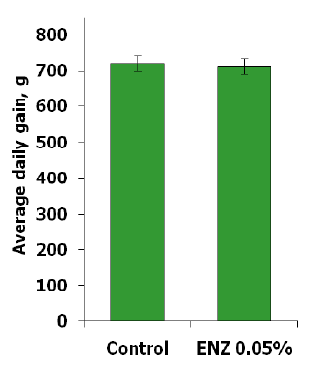

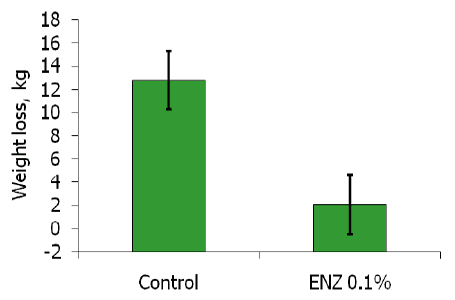

Growing-finishing pigs can also be benefitted by the use of NSPases as their ability to utilize energy in the feed improves. Swine producers can reduce energy content in the diets without sacrificing growth performance when exogenous NSPases are supplemented (Figure 7; Kim et al., 2006b). Use of NSPases in lactation diets helped sows often possessing a limited voluntary nutrient intake to preserve body tissues without reducing milk production as their energy digestibility improved (Figure 8; Ji and Kim, 2004). As previously described, exogenous microbial enzymes produced by bio-fermentation has made a great contribution to swine production by improving production efficiency.

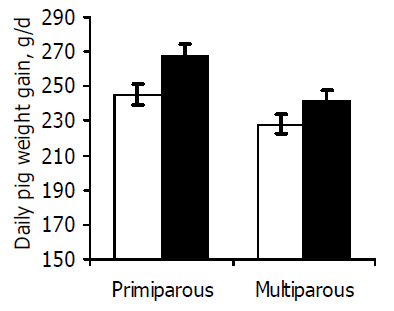

YEAST METABOLITES

There have been many types of probiotics and prebiotics introduced as potential alternatives to the use of supplemental antibiotics as growth promoters. These probiotics and prebiotics mainly target reducing pH and/or reducing population of pathogenic microorganisms in hind gut. However, lack of consistent research evidences showing benefits of probiotics and prebiotics limits application in swine diets. Yeast metabolites have newly been introduced in swine diets. Yeast metabolites are also called yeast culture that includes concepts of both probiotics and prebiotics. Yeast metabolites are first introduced to dairy producers and known to improve dry matter intake of dairy cows increasing milk production (Putnam et al., 1997). Recent research with sows conducted at a large commercial swine operation introduced that yeast metabolites may increase milk production for litter growth (Figure 9; Kim et al., 2008).

Figure 6. Height of villus in jejunum of nursery pigs fed diets with or without NSPases for 4 week after weaning. Adapted from Kim et al. (2003).

Figure 7. Growth performance of pigs fed a diet containing metabolizable energy at the NRC requirement or a diet containing reduced metabolizable energy (5%) with NSPases. Adapted from Kim et al. (2006b).

Yeast metabolites are produced by bio-fermentation of cereal grains by Saccharomyces ceravisiae under anaerobic liquid state condition. Yeast cells would preserve essential metabolites for their survival instead of generating ATPs under an anaerobic condition. Solid state fermentation follows liquid state fermentation encouraging further production of metabolites that can be dried and used in feed application. Yeast metabolites, therefore, include metabolites produced during anaerobic fermentation as well as cell content and cell wall components. Repeatable results are obtained showing dietary supplementation of yeast metabolites improves milk production in sows, even though it is premature to conclude which component in yeast metabolites helps milk production at this moment.

FERMENTED INGREDIENTS

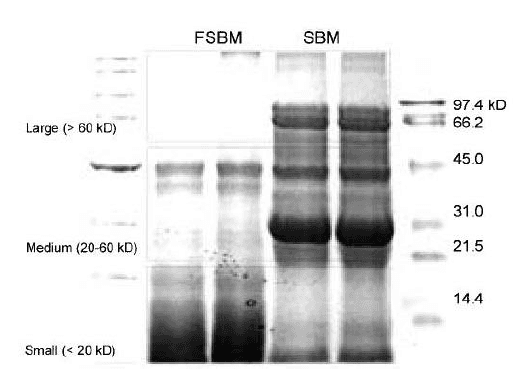

Vegetable protein sources including soybean meals have economical advantages over expensive animal protein sources. However, these vegetable protein sources often contain anti-nutritional factors limiting their application in feeding newly weaned pigs with immature gut structure that can be damaged by anti-nutritional factors. There are several anti-nutritional factors found in vegetable protein sources including trypsin inhibitor, lectin, flatulence producing compounds, phytate, glycinin, β-conglycinin, etc. Some of anti-nutritional factors can be destroyed by feed processing such as heating and cooking. Newly weaned pigs with limited HCl in stomach and enzymatic secretion in small intestine can have difficulties to digest proteins with complex structures and large molecular weights (Cranwell, 1985; Chapple et al., 1989). There has been an effort to improve vegetable protein sources by reducing anti-nutritional factors using bio-fermentation technology. Aspergillus oryzae and Bacillus subtilis have traditionally been used preparing soybeans via fermentation. Careful selection of these microorganisms for high activity in specific feed ingredient allowed preparation of novel fermented vegetable protein sources. This fermentation process by Aspergillus oryzae and Bacillus subtilis reduced trypsin inhibitor below a detection limit, reduced phytate content by 4-folds, reduced size of peptides for suitable for digestion, and reduced contents of glycinin and β- conglycinin that are known as allergenic compounds in gut (Figure 10; Hong et al., 2004).

Figure 8. Weight loss of sows fed diets with or without NSPases during 21-d lactation. Adapted from Ji and Kim (2004).

Figure 9. Weight gain of nursing pigs from sows fed diets with or without yeast metabolites during gestation (12 g/d) and lactation (15 g/d) at a commercial swine operation (n = 335). Adapted from Kim et al. (2008).

Figure 10. Distribution of peptides in soybean meals (SBM) before and after fermentation by Aspergillus oryzae. Adapted from Hong et al. (2004).

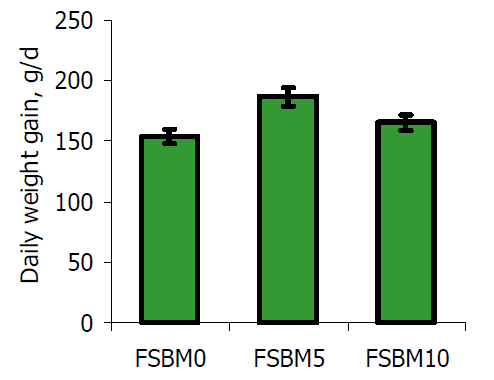

Use of these fermented vegetable protein sources in nursery diets improved growth efficiency of newly weaned pigs compared to pigs fed same vegetable protein sources without fermentation. Fermented vegetable protein sources could also replace the use of animal protein sources such as whey protein concentrates and spray dried plasma protein in part without compromising growth performance (Figure 11; Kim et al., 2009). It is a great contribution to swine industry applying bio-fermentation technology to prepare relatively inexpensive vegetable protein sources replacing the use of expensive animal protein sources in swine diets.

CONCLUSIONS

This article reviewed examples of application of biofermentation technology to advance swine nutrition based on the author´s own research experience. Production of feed grade supplemental amino acids by bio-fermentation allowed nutritionists to formulate accurate feed for optimal lean growth and reduced nitrogen excretion. Recent issues with high feed grain prices caused potential feed quality problem. Bio-fermentation allowed nutritionists to use exogenous supplemental enzymes such as phytase and NSPases in swine diets improving nutrient utilization and reducing nutrient excretion to environment. Yeast metabolites are also produced by bio-fermentation and repeatedly shown to improve milk production of sows during early lactation even though actual mechanisms are still to be investigated. Bio-fermentation technology also allowed nutritionists to prepare vegetable protein sources with large protein molecules and anti-nutritional factors suitable for feeding newly weaned piglets as selected microorganisms significantly reduces specific antinutritional factors and size of peptides. Preparations of vegetable protein sources suitable for newly weaned pigs will greatly contribute to swine nutrition by providing efficient alternatives to the use of animal protein sources that are often expensive and somewhat against societal preference. Considering few examples listed above, biotechnology has closely influenced improvement of production efficiency of swine industry. As we have limited resources to produce meat to satisfy ever increasing global demands, extensive adaptation of biotechnology to enhance production efficiency should be continued. However, at the same time, wise and careful application of bio-technology should be considered to ensure production of safe food and to meet the expectation of our society.

Figure 11. Growth performance of nursery pigs (week 1 and 2 postweaning period) fed diets containing fermented soybean meal replacing whey protein concentrates based on equal protein values. Contents of lactose, lysing, threoning, tryptophan, and methionine were balanced among diets. Adapted from Kim et al. (2010).

REFERENCES

Beeson, W. M., H. D. Jackson and E. T. Mertz. 1953. Quantitative threonine requirement of the weanling pig. J. Anim. Sci. 12:870.

Brinegar, M. J., H. H. Williams, F. H. Ferris, J. K. Loosli and L. A. Maynard. 1950. The lysine requirement for the growth of swine. J. Nutr. 42:129-138.

Chapple, R. P., J. A. Cuaron and R. A. Easter. 1989. Effect of glucocorticoids and limiting nursing on the carbohydrate digestive capacity and growth rate of piglets. J. Anim. Sci. 67:2956-2973.

Cranwell, P. D. 1985. The development of acid and pepsin (EC 3.4.23.1) secretory capacity in the pig; the effects of age and weaning. 1. Studies in anaesthetized pigs. Br. J. Nutr. 54:304- 320.

Hong, K. J., C. H. Lee and S. W. Kim. 2004. Aspargillus Oryzae GB-107 fermentation improves nutritional quality of food soybeans and feed soybean meals. J. Med. Food 7:430-436.

Ji, F. and S. W. Kim. 2004. Effects of carbohydrase supplement on lactation performance of primiparpous sows. Asian-Aust. J. Anim. Sci. 17:533-537.

Kim, S. W. 1999. Mammary gland growth and nutrient mobilization in lactating sows: A dynamic model to describe nutrient flow. Ph.D. Thesis. University of Illinois at Urbana- Champaign, IL.

Kim, S. W. and D. H. Baker. 2003. Use of enzyme supplements in pig diets based on soyabean meal. Pig New Info. CABI. 24:91N-96N.

Kim, S. W. and G. Wu. 2004. Dietary arginine supplementation enhances the growth of milk-fed young piglets. J. Nutr. 134:625-630.

Kim, S. W., D. L. Knabe, K. J. Hong and R. A. Easter. 2003. Use of carbohydrases in corn-soybean meal-based nursery diets. J. Anim. Sci. 81:2496-2504.

Kim, S. W., R. D. Mateo, Y.-L. Yin and G. Wu. 2007a. Functional amino acids and fatty acids for enhancing production performance of sows and piglets. Asian-Aust. J. Anim. Sci. 20:295-306.

Kim, S. W., J. H. Zhang, K. T. Soltwedel and D. L. Knabe. 2006b. Use of carbohydrases in corn-soybean meal-based growerfinisher pig diets. Anim. Res. 55:563-578.

Kim, S. W., M. Brandherm, M. Freeland, B. Newton, D. Cook and I. Yoon. 2008. Effects of yeast culture supplementation to gestation and lactation diets on growth of nursing piglets. Asian-Aust. J. Anim. Sci. 21:1011-1014.

Kim, S. W., E. van Heugten, J. Fei and R. D. Mateo. 2010. Fermented soybean meal as a vegetable protein source: I. Effects on growth performance of nursery pigs. J. Anim. Sci. 88:214-224.

Mateo, R. D., G. Wu, F. W. Bazer, J. C. Park, I. Shinzato and S. W. Kim. 2007. Dietary L-arginine supplementation enhances the reproductive performance of gilts. J. Nutr. 137:652-656.

Mateo, R. D., G. Wu, H. K. Moon, J. A. Carroll and S. W. Kim. 2008. Effects of dietary arginine supplementation during gestation and lactation on the performance of lactating primiparous sows and nursing piglets. J. Anim. Sci. 86:827- 835.

Meade, R. J. and W. S. Teter. 1956. The influence of L-lysine supplementation of 12, 14, and 18 percent protein cornsoybean oil meal diets upon nitrogen balance of growing swine. J. Nutr. 60:609-618.

Putnam, D. E., C. G. Schwab, M. T. Socha, N. L. Whitehouse, N. A. Kierstead and B. D. Garthwaite. 1997. Effect of yeast culture in the diets of early lactation dairy cows on ruminal fermentation and passage of nitrogen fractions and amino acids to the small intestine. J. Dairy Sci. 80:374-384.

Shelton, D. C., W. M. Beeson and E. T. Mertz. 1951. Quantitative DL-tryptophan requirement of the weanling pig. J. Anim. Sci. 10:73-79.

Wu, G., D. A. Knabe and S. W. Kim. 2004. Arginine nutrition in neonatal pigs. J. Nutr. 134:2783S-2790S.

Wu, G., F. W. Bazer, T. A. Davis, L. A. Jaeger, G. A. Johnson, S. W. Kim, D. A. Knabe, C. J. Meininger, T. E. Spencer and Y. L. Yin. 2007. Important roles for the arginine family of amino acids in swine nutrition and production. Livest. Sci. 112:8-22.

Wu. G., F. W. Bazer, T. A. Davis, S. W. Kim, P. Li, J. M. Rhoads, M. C. Satterfield, S. B. Smith, T. E. Spencer and Y. Yin. 2008. Arginine metabolism and nutrition in growth, health and disease. Amino Acids 37:153-168.

Wu, G., F. W. Bazer, T. A. Davis, S. W. Kim, J. M. Rhoads, M. C. Satterfield, S. B. Smith, T. E. Spensor and Y. L. Yin. 2009. Arginine metabolism and nutrition in growth, health and disease. Amino Acids 37:153-168.

This article was originally published at the Asian-Australasian Journal of Animal Science Vol. 23, No. 6 : 825 - 832 , June 2010. Engormix.com thanks for this huge contribution.

.jpg&w=3840&q=75)