Detection and Prevention of Milking Routine Problems by Computerized Monitoring of Milking Irregularities

Published: November 24, 2014

By: Ralph Ginsberg1, D. Rak2, A. Arazi2, and E. Aizinbud2 (1National Service for Udder Health and Milk Quality – Israel Dairy Board, Yehud, Israel 2 S.A.E Afikim, Kibbutz Afikim, Israel)

Electronic computer monitoring of herd and individual cow performance is common in Israeli dairy herds, and allows characterization and quantification of milking efficiency as well as parlor throughput. Eicker et al. (2000) theorized that computerized parlor data could be used to monitor how milkers used the equipment in the parlor. The advantage of ACR compared with manual removal is well known. One of milking routine violations is “overriding” of the ACR settings.

Historically cows were considered milked out when the milk flow rate decreased to 200 gr/min and most ACR's were set to this level. Sagi 1978 and Rasmussen 1993 concluded that the cluster can be detached at a flow rate of 400 gr/min with no negative effect on the milk yield. Milking time was also significantly shorter. Between 1997 and 2002 Steward together with various associates showed the effects of gradually raising take off settings with similar results.

A study was carried out to examine if computer monitoring of the dairy herd can help in the assessment of the milking routine on individual farms, to advise on possible shortcomings, and to monitor recommendations on improvements to the milking routine, particularly violations of “overriding” the ACR settings.

Materials and Methods

A survey was conducted at 30 randomly selected farms using the milking "Irregularities Report" of the Afimilk management software system (SAE Afikim, Kibbutz Afikim, Israel) to monitor: 1. Irregular take-offs - kick-offs or milker intervention. 2. Slow cows - Cows milking longer than 8 minuets. 3. Low flow time removal (Low milk flow was classified as less than 1 kg (2.2lb)/min). Default ACR settings for Afikim milk meters in Israel are 0.48kg (1.05 lb) milk/min.

All farms were monitored for ten consecutive days prior to the study. Milking routine was monitored visually with an emphasis on the milkers’ experience and skill. Farms with extreme milking irregularities were instructed on optimum udder preparation and not to manually override the automatic take-off settings.

Table 1. Milking irregularities as determined in a survey on 30 farms (7292 cows)

On one of the herds surveyed milkers routinely canceled the manufacturers default ACR settings resulting in irregular take-offs considerably higher than the average. Milkers were instructed not to "override" the ACR and to reattach the cluster only if the milk meter indicated that the cow had milked less than the designated minimum percent of milk per milking. Results were immediate and unmistakable.

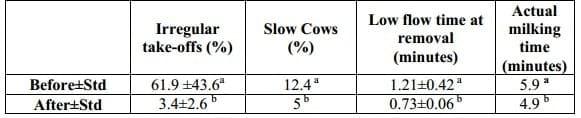

Table2. Milking Irregularities – two weeks prior and two weeks after the change in the milking routine.

Means of the same column with different superscripts are significantly different (P<0.05)

Table3. DHI data before and after the changing the milking routine (15/09/09)

Discussion

DiscussionResults of this survey showed large variations in milking irregularities with many of the herds overriding the ACR settings. The findings of this field study in commercial herds support the results of previous studies indicating that default ACR settings can be set at 0.48 kg (1.05 lb) milk/min with no detrimental effects on milk yield, udder health and milk quality. Computer detection of milking irregularities at one of the herds showed that it was possible to improve parlor performance and other shortcomings resulting from overriding ACR settings. Computerized monitoring in the milking parlor provides a data base for a fast and efficient clarification of milking irregularities. This data base can be used to correct the reasons for these phenomena and monitor the results.

References

Eicker, S., S. Stewart, D. Reid, and P. Rapnicki. New tools for measuring the effect of stimulation and take off on milk flows. Proc. Annual Meeting of the National Mastitis Council. 127-133, 2000.

Rasmussen, M.D. Influence of switch level of automatic cluster removers on milking performance and udder health. Journal of Dairy Research 60(3):287-297. 1993.

Sagi, R. Milk flow rate and end of milking detectors. Proc. Annual Meeting of the National Mastitis Council. 328-334 1978.

Stewart, S.C., et al. Effects of automatic cluster remover settings on average milking duration, milk flow, and milk yield. Journal of Dairy Science 85(4):818-823. 2002.

This paper was presented at the National Mastitis Council (NMC) Annual Meeting, Jan 2011 in Arlington, Virginia.

Related topics

Authors:

Join to be able to comment.

Once you join Engormix, you will be able to participate in all content and forums.

* Required information

Would you like to discuss another topic? Create a new post to engage with experts in the community.

Create a postC.Y.C. Agricultural Technologies & Management Ltd

16 de diciembre de 2014

Michael

A good pre-milking teat preparation, a short, consistent interval until attachment, and calm cows are prerequisites for detachment at high flow rates.

Overmilking is defined as when the flow of milk from the alveoli to the teat cistern is less than the flow of milk from the teat.

The distribution of milk in vast majority of cows is 55% in the back quaters and 45% in the front. Today we have cluster milked cows with take off settings of 1.2Kg with no detrimental effect.

I have mlking robots set at 400 ml' with no problems.

15 de diciembre de 2014

What level of milk flow would be set when milking by robot where each quarter if taken off individually.

.jpg&w=3840&q=75)