Bioconversion of palm kernel meal for aquaculture

Bioconversion of palm kernel meal for aquaculture: Experiences from the forest region (Republic of Guinea)

Published: May 23, 2012

By: Saurin Hem, Sékou Toure, Cé Sagbla and Marc Legendre

Summary

Proteins and fats locked in palm kernel meal cannot be used directly by fishes. Enzyme from maggots (Hermetia illucens larvae) lyses and extracts those nutrients which are consumed as food. Biomasses of maggots produced can be used to feed fishes. This innovation opens a new hope for many African countries where so much agro-industry by-products exist such as palm kernel meal, groundnut meal, cotton seed meal. The different aspects involved in this discovery are explained before the sequence of processes up to final discovery is described.

Key words: Hermetia illucens, black soldier fly, palm kernel meal, rural aquaculture, agro-industry by-products, fishmeal replacement, bioconversion.

INTRODUCTION

Searching for new aquaculture feedstuff, other than the usual commercial pellets, means looking forward to solve the problem faced frequently in the African rural context, where feedstuff supplies are difficult. The high cost (including transportation) of fish pellet and its ingredients such as fishmeal, fish-oil, soybean, etc. constitutes a real constraint for the development of aquaculture. The idea to apply acadja or brush-park fisheries in brackish water lagoon (Hem and Avit, 1994) as an extensive aquaculture system (without feeding with pellets) is one of the promising responses to this rural aquaculture constraint in West Africa. Research programs to develop rural selfsufficient technology are becoming an urgent need in order to save rural life from the impacts of globalization such as energy dependence or other raw products importation.

The Forest Region of Guinea Republic is a land locked region (Figure 1). Nevertheless, the economical exchanges as well as food supplies have existed traditionally with coastal regions of Liberia and Sierra Leone. However, the situation has changed to nearly collapse since 1990 when the civil war started in Liberia and since 1997 in Sierra Leone. As a consequence of the migration of the refugees, the population in the Forest Region has almost doubled within a short period of time, increasing from 1.3 million to 2 million people. As a direct consequence from those circumstances, there is a real critical food security issue. Considering the consumption rate of fish as example, the rate was as low as 2.5 Kg/capita/year while at the same time in the coastal region nearby Conakry the rate has remained acceptable at 15 kg/capita/year.

When the Institut de Recherche pour le Développement (IRD) in 1999 initiated a research program to develop aquaculture in the Forest Region (Republic of Guinea), self sufficient concept was declared firmly as terms of reference of the project. Acadja-bamboo in ponds (Hem et al., 1995), applied from Ivory Coast experiences, was introduced. Rice-fish culture, inspired from rural practices in Southeast-Asia, was also tested (Ali, 1992; Chapman, 1992). All these new techniques may improve fish biomass, but in terms of harvested yield (350 kg/ha) it remained far from farmers´ expectation. Therefore, one gosa is to assess in the study zones all kinds of agroindustrial by-products available as feedstuff sources for fish. This led us to consider palm oil and rubber industries and to cooperate with Soguipah (Société Guinéenne de Palmier à huile et d´Hévéa), a national company that owns those two agro industries.

Figure 1. Map showing the position of Forest Region which is one of the four natural regions of Guinea Republic having common border with three countries Sierra Leone, Liberia and Ivory Coast.

This paper concerns only Palm Kernel meal (PKM) bioconversion, a natural process used to transform this by-product to make it usable for feeding fish. Its composition in terms of nutriments will be also presented. A brief explanation on the sequence, which has driven us to discover the insect H. illucens, also known as Black soldier (BS), will be given. The first empirical culture method of BS larvae on PKM is hereby presented as well as the results on the first use of H. illucens larvae as feedstuff in tilapia culture.

MATERIALS AND METHODS

Palm oil industry by-products

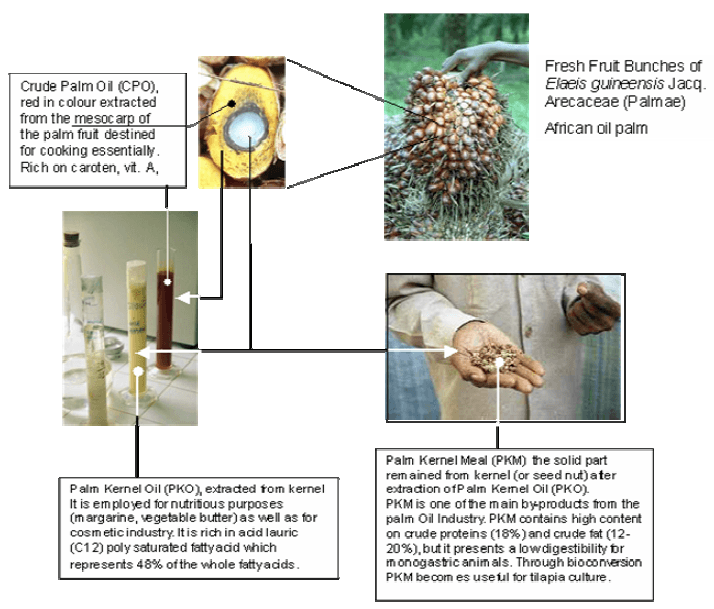

The palm tree (Elaeis guineensis, Jacq.) is native of tropical West Africa. The fruits grow in bunches and consist essentially of a soft outer skin, which is reddish when it becomes ripe (Figure 2). The palm fruit produces two types of oils: the first category of oil named crude palm oil (CPO), red in colour, is extracted from the fibrous external layer, the mesocarp of the fruit. CPO is usually used as cooking oil. Inside the mesocarp there is a hard nut (endocarp) also known as the shell which encloses a kernel, itself containing a second type of oil, the palm kernel oil (PKO). The PKO contains essentially saturated fatty acids (Anonyme, 2001): lauric acid (C12: 48%), myristic acid (C14: 16%) and oleic acid (C18: 15%). It is used as basic ingredients for margarine production, confectionery, animal feeds and cosmetics such as soaps, creams.

To process PKO, the first step consists of breaking the hard shell (Akubuo and Eje, 2002) and separating from the kernel. The Palm Kernel Meal (PKM) is the solid part remaining from palm kernel after the extraction of PKO by a mechanical screw pressing. The palm kernel meal, also known as palm kernel expeller (PKE) or Palm Kernel Cake (PKC), has high protein (18-20% of crude proteins) and lipid contents (12 - 20% of crude fats). This variability of crude fats concentration is related to the technical extraction process mechanical only or combined with solvent used (Chin, 2002). In our case study, PKO were extracted by mechanical screw pressing only. Therefore nutrients level remaining in PKM is usually higher (18% of crude proteins and 20% of crude fats). PKM is rich in arginine, leucine and cysteine but deficient in lysine (Pérez, 1997) which may be increased by fermentation (Iluyemi et al., 2006) or supplementation with other lysine-rich sources, such as molasse or vegetable oil.

Every year, Soguipah oil factory have produced nearly 1000 metrics tons of PKM. A very few quantity have been tried with monogastric animals, such as swine, poultry and fish. The uses of palm kernel meal have been tried with the Nile tilapia as well as with juveniles of Labeo senegalensis, but lower values results of PKM digestibility has been recorded (Omoregie, 2001). The low digestibility of the nutrients from PKM has been found and explained by the high levels of non-starch polysaccharides (NSP) in the cell wall materials (Düsterhöft, 1993). The NSP is known as an antinutritional factor impairing the digestibility of nutrients contained in PKM (Choct, 2001). Only ruminants may use PKM with a greater efficiency because of the action from microorganisms (bacteria and fungus) and their enzymes breaking down the cellulose walls of the cells (Lim et al., 2001). A few quantities of PKM have been tried locally with ruminants (sheep or cattle) but farmers preferred to feed extensively with green grass. Overall, a large quantity of PKM remains unused. Among other agro-industrial by-products, considering the percentage of proteins in the dried mater and the price of PKM, the cost effectiveness of proteins remains cheapest in PKM (Shayne, 2000).

Figure 2 . Palm Kernel Meal (PKM): its origin and its composition in nutrients.

Attempt to use PKM through fermentation process

As a consequence of what we observed in ruminants and through many articles (Düsterhöft, 1993; O´Mara et al., 1999; Choct, 2001), micro-organisms through their complex enzymes in the digestive track could play a key role in the biodegradation of PKM. From this point, an attempt of PKM fermentation was attempted by simply mixing the PKM with rumen contents and water. After two weeks of culture, fermented PKM (mixed with rice bran) was used to feed Oreochromis. However, the fermented PKM, blended with rice bran was not appealing to tilapia. The unused fermented PKM, because of the smell, are stocked at the backyard of the station. After two weeks, we have observed around the area, many chickens and birds feeding from it. Surprisingly we discovered that inside the containers, thousands of maggots have developed within fermented PKM. The maggots were larvae from the insect Hermetia illucens.

The tilapia enjoyed the live maggots feed.

Hermetia illucens (Linnaeus) (Stratiomyidae – Diptera)

At first sight, H. illucens (also known as Black Soldier fly) larvae were not identified as such. They were found, as mentioned above, among fermented PKM forgotten at the backyard of the station. We initially mistook BS larvae for common blow flies maggots. And when we saw sometimes Black Soldier flies (H. illucens) alone, we were again mistaken by taking them as wasps. However, the larvae morphology and their size and weight (24 mm long, 8 mm wide and 240 mg weight) were so unlike fly larvae. Secondly, the duration of metamorphosis observed on those larvae (from eggs up to pupa stage) was much longer. The remarkable difference also concerned the pupa morphology. Because of this, we decided to enclose 50 pupae (at the black stage) in a 4 L transparent plastic container with a cover where we made small holes for air to pass through. After two to three weeks, we found in the plastic container a few insects black in colour hatched leaving empty black soughs. From that time it was clear that the larvae appeared among the fermented PKM were not from the ordinary flies (blow or green flies). The specimens of insects and larvae were preserved in 75% ethanol. The identification was the book "Immature insects" (Stehr, 1991; Chu and Cutkomp, 1992). It was clear that the larvae we have found, are the members of Stratiomyidae family and Diptera Order. Further search on the Internet led to know more about the insect. H. illucens has been recognized by many authors and scientists as one of the most useful species (Warburton et al., 2001). Recent studies (Sheppard, 1992; Newton et al., 1995) have shown that H. illucens, in larvae stage, have been used to reduce chicken and pig waste to a non-polluting residue in a matter of days under ideal conditions. Hermetia larvae biomass has been also used to feed fish and chicken.

In terms of biodiversity, H. illucens have been found in a large geographic range, around the world throughout warmer regions between latitudes 45° North and 45° South including the Australasian and Oceanic Regions like New Caledonia (Rageau, 1957; Cochereau, 1970,1974), Solomon Is, Vanuatu, Western Samoa, French Polynesia, etc.

Before making the decision to work on H. illucens, some previous investigations are needed to ensure that the insect species are not dangerous or have undesired negative side effects. According to many investigations, BS is well known as a useful insect (Sheppard, 1992; Newton et al., 1995; Leclercq, 1997). The short duration of the adult life may explain the character of the non pest aspect of Hermetia fly. However, one myasis case has been mentioned in Costa Rica (Calderon-Arguedas et al., 2005). Hermetia larvae is also used, in medical jurisprudence (Turchetto et al., 2001), as a forensic tests to esti-mate the period of a crime detection. Considering many advantages related to the BS role in biodegradation, it was reasonable for us to continue to carry on working with H. illucens.

Production of BS larvae

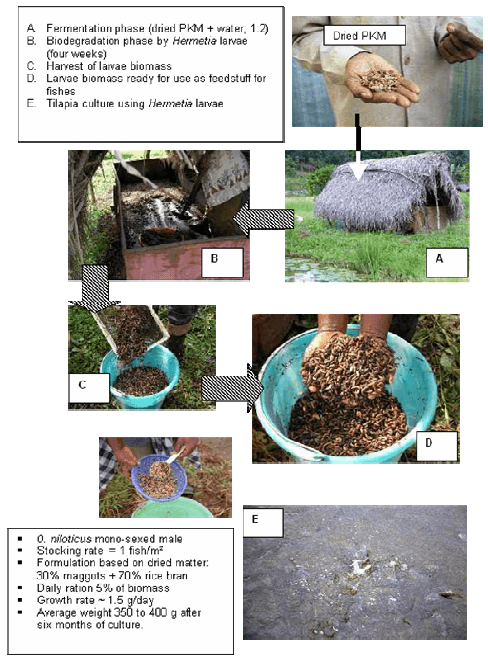

In terms of systematic classification, H. illucens is known with precision, but by contrast, their biology, biotope and habitat use as well as their breeding ecology, remain poorly known under tropical climate conditions. The production techniques applied during the year 2001 were based purely on empirical observations. The first mass cultures were done in rectangular iron tanks, dimensioned as follow: 1.5 x 3 x 0.4 m deep (Figure 3A). The whole structures were kept 0.5 m above ground. Eight tanks were used for the culture. The culture medium (Palm Kernel Meal, mixed with water: 1 kg PKM for 2 L of water) was placed on the culture tank bottom. The layer thickness of the medium must be 3 to 4 cm (Figure 3B). The culture tank as dimensioned above may receive 80 kg of dried PKM.

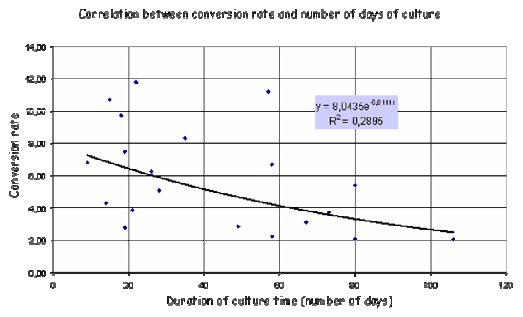

The optimum time of culture was not yet known at that time. The harvests have been executed according to the estimation at a rough guess on the quantity of larvae appearing in the medium. The larvae were separated from the medium by filtering and cleaning with water (Figures 3C and 3D). Among the data recorded, we have considered the amount of input PKM, the starting date, the harvest date and the biomass of larvae collected. When some time the cultures were destroyed by rain flood or by predation from wild animals, those data were not considered. The results showed that the conversion rate (the ratio between the quantity of PKM input and the biomass of larvae harvested) was very variable with an average = 5.8 and a standard deviation 3.2.

Through the graphic interpretation (Figure 4) by placing conversion rate (PKM kg/Biomass larvae kg) on the Y-axis and duration of culture time (the numbers of days between the started date - and the harvested date) on X axis, we observed an inverse correlation between the two parameters (r = negative). It means when the culture duration is longer, the conversion rate is low. Otherwise the conversion from PKM to larvae biomass was more efficient. According to this result, it is clear the optimal culture time is more than three weeks. From then on we fixed 4 weeks as the optimal time for harvest. Tanks must be covered by chicken wire in order to protect the culture from rats, lizards, birds, or other animals. The tanks must be also roofed otherwise the whole culture may be flooded by rain.

Application of Hermetia illucens larvae as feedstuff in tilapia culture

This is not the first time Hermetia larvae has been used for feeding fish. Bondari and Sheppard (1987) have tried to use BS larvae since 1981 to feed catfish Ictalurus puntatus and Oreochromis aureus. The authors have found that growth was satisfied of the two species feeding with BS. Chopping of BS larvae improved weight gain and efficiency of the utilization.

RESULTS AND DISCUSSION

Since June, 2002, production of BS larvae in Forest Region has become a routine. Production about 30 kg of fresh BS larvae have been obtained weekly from the culture. Direct feeding with live BS larvae to tilapia in pond has confirmed that the fishes appreciated greatly this new feedstuff (Figure 3E). From that stage we have proposed for the first time to design a simple formula based on BS larvae and rice bran (70% of rice bran and 30% BS larvae) the only ingredients available in the region. The proportion of each ingredient is based on their dried matters (6% of water in rice bran and 70% of water in SB larvae).

Four hundred males Tilapia about 20 g of body weight (Oreochromis niloticus) were placed in pond (20 x 20 x 1.5 m). The feeding rate was started from 7.5% of biomass and ended at 4% at the sixth month before harvest.

The mortality was relatively high at the beginning of the experimentation (3% during the two first months) and stabilized around 1% until harvest. At the end of the culture the individual daily growth rate was at the average of 1.8 g/day was recorded. It means the growth rate is 3.5 times faster than culture feeding with rice bran alone (0.52 g/day).

This first result has opened a new desire to promote aquaculture in the region. December, 2003 marked the end of the project, but the culture of BS continued as well as tilapia culture. Now, replication of the experiments have confirmed the process. The value of growth rate from 1.5 to 2 g/day, resulted from 6 months of culture of tilapia male (density of one per m²), from 20 g initial weigh to 300 g final weigh. The formulation of 30% of BS larvae and 70% of rice bran, based on dried mater, has become the standard in the studied zone.

Figure 3. Bioconversion process is started from fermentation of PKM (with water). After one week, the smell of PKM fermented attracts the insect Hermetia illucens to come and lay their eggs on it. Hermetia larvae biodegrades the PKM and develops within the medium (PKM). Biomass of larvae obtained is used as foodstuffs for tilapia culture.

Figure 4. Relationship between the conversion rate and the duration of culture (number of days).

Conclusion and recommendations The finding of this bioconversion process on PKM by black soldier larvae has opened a new hope for tilapia rearing in the rural areas where agricultural by-products are often available. This experience can be transferred into others regions and countries in West Africa where PKM are abundant. The time limit of our project did not permit us to accomplish the research on BS life cycle. So far the study referred to data from literatures published in the United Stated and Australia. This lack of knowledge concerning tropical zones need to be filled.

PKM is not the only by-product that can be used as medium for biodegradation. Future attempts should include other organic by-products or domestic wastes (Newton et al., 1995). Research technique must focus on mass production of BS larvae in order to respond to the real scale of fishmeal replacement need. For a large extension program, we must keep in mind and concentrate effort on rural conditions in order to innovate the low key technology that do not require heavy cost investments. Once the mass production of BS larvae is achieved, research must continue on nutrition aspects in order to perform the formulation for fish or for animal feed in order to reach a better profitability for rural farmer.

Acknowledgement

The authors would like to express a special thank to Dr Emmanuel Paradis who has kindly accepted to revise and refine this article.

REFERENCES

Akubuo CO, Eje BE (2002). Palm Kernel and Shell Separator Biosyst. Eng. 81: 193-199.

Ali A (1992). The rice-fish ecosystem. ASFA-1:-Biological-Sciencesand- Living-Resources (Q1) p. 3.

Anonyme (2001). Palm Kernel Oil - Composition and Properties, FOSFA International (Association for international trading in oils, fats and oilseeds).

Bondari K, Sheppard DC (1987). Soldier fly, Hermetia illucem L., larvae as feed for channel catfish, Ictalurus punctatus (Rapisnesques) and blue tilapia, Orcochromis aureus (Steindachner). Aquacult. Fisheries Manage. 18: 209-220.

Calderon-Arguedas O, Barrentes Jm, Solano ME (2005). Miasis entérica por Hermetia illucens (Diptera: Stratiomyidae) en una paciente geriátrica de Costa Rica. Parasitol. Latinoam 60: 162-164.

Chapman G (1992). Fry nursery techniques in the rice-fish systems of northeast Thailand. Rice Fish Resaerch and Development in Asia.

Chin FY (2002). Utilization of palm kernel cake (PKC) as feed in Malaysia, Asian Livestock, FAO Regional Office Bangkok, Thailand, pp. 19- 23.

Choct M (2001). Nutritional Constraints to Alternatives Ingredians. American Soybean Association – Tech. Bull. AN31-2001, p. 9.

Chu HF, Cutkomp LK (1992). Immature insects. Wm. C. Brown Publishers, Dubuque.

Cochereau P (1970). Observations sur la faune des bois en voie de décomposition en forêt Néo-calédonienne. Cah.ORSTOM, Sér. Biol. 12: 123-127.

Cochereau P (1974). Ebauche d´un inventaire faunistique de l´ïle Mangareva (archipel des gambier). Cahiers du Pacifique tome 2: 479-532.

Düsterhöft EM (1993). Characterisation and enzymic degradation of non-starch polysaccharides in lignocellulosic byproducts: a study on sunflower meal and palm-kernel meal. Wageningen Dissertation Abstracts - WAU dissertation p. 1593.

Hem S, Avit JBLF, Cissé A (1995). Acadja as a system for improving fishery productivity, In: Symoens J, Micha JC (Eds.), The management of integrated freshwaler agro-piscicultural ecosystems in tropical areas, Brussels. Technical Centre for Agricultural and Rural Co-operation (CTA), Brussels, 16-19 May 1994, pp. 423-435.

Hem S, Avit JLB (1994). First results on "Aacja-enclos" as an extensive aquaculture system (West Africa). Bull. Mar. Sci. 55: 1038-1049.

Iluyemi FB, Hanafi MM, Radziah O, Kamarudin MS (2006). Fungal solid state culture of palm kernel cake. Bioresour. Technol. 97: 477-482.

Leclercq M (1997). A propos de Hermetia illucens (Linnaeus, 1758) ("soldier fly") (Diptera Stratiomyidae: Hermetiinae) Bull. Annls. Soc. R. Belge Ent. 133: 275-282.

Lim H-A, Ng W-K, Lim SL, Ibrahim CO (2001). Contamination of palm kernel meal with Aspergillus avus affects its nutritive value in pelleted feed for tilapia, Oreochromis mossambicus School of Biological Sciences, Universiti Sains Malaysia, Penang 11800, Malaysia. Aquacult. Res. 32: 895-905.

Newton GL, Sheppard DC, Thompson SA, Savage SI (1995). Soldier Fly Benefits Annual Report, Animal & Dairy Science, CAES, UGA, pp. 311-321.

O´Mara FP, Mulligan EJ, Cronin EJ, Rath M, Caffrey PJ (1999). The nutritive value of palm kernel meal measured in vivo and using rumen fluid and enzymatic techniques. Livestock Prod. Sci. 60: 305-316.

Pérez R (1997). Feeding pigs in the tropics - Chapter 4 African oil palm. Food and Agriculture Organization of the United Nations Rome.

Rageau J (1957). Possibilités de lutte contre les mouches en Nouvelle- Calédonie. Institut Français d´Océanie.

Shayne L (2000). Cost effective supplement purchasing, In: Nutrition PP (Ed.), Dairy Page, Official website of the Queensland Dairyfarmers´ Organisation Ltd., Brisbane QLD 4003.

Sheppard DC (1992). Large-scale Feed Production from Animal Manures with a Non-Pest Native Fly. FINL 5.

Stehr FW (Ed.) (1991). Immature Insects. Kendall/Hunt Publishing Company, Dubuque.

Turchetto M, Lafisca S, Costantini G (2001). Posmortem interval (PMI) determined by study sarcophagous biocenoses: three cases from the province of Venice (Italy). Forens. Sci. Int. 120: 28-31.

Warburton K, Dart P, Hallman V, Taylor M (2001). Performance comparison of earthworms and soldier fly larvae in the processing of sewage sludge, In: (AWTT) AWTT (Ed.), Scheme Project 1003-01- 001, Dept. of Zoology, University of Queensland, Queensland, p. 11.

This article was originally published at the African Journal of Biotechnology Vol. 7 (8), pp. 1192-1198, 17 April, 2008. Engormix.com thanks for this contribution.

Related topics

Authors:

Join to be able to comment.

Once you join Engormix, you will be able to participate in all content and forums.

* Required information

Would you like to discuss another topic? Create a new post to engage with experts in the community.

Create a post2 de septiembre de 2012

This paper is published in 2008. is there any latest study on this project of bsf mass culture?

.jpg&w=3840&q=75)